Preparation method for grafting maleic anhydride onto plasma activated carbon nano tube

A plasma and carbon nanotube technology, applied in the field of carbon materials, can solve the problems of short polymerization chain length, low reaction efficiency, long reaction time, etc., and achieve the effects of improving reaction speed and degree, uniform surface coating, and convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 0.2g of carbon nanotubes, place them in the plasma reaction chamber, and evacuate to 1.0×10 -4 After Pa, pass high-purity argon gas for 15 minutes (air pressure is 13.3Pa, gas flow rate is 20ml / min); discharge treatment at a power of 60W for 10 minutes, and pass oxygen for 20 minutes (air pressure is 13.3Pa, gas flow rate is 20ml / min), take out carbon nanotubes;

[0034] Dissolve 6.8g of maleic anhydride in 100ml of xylene at 60°C to obtain a maleic anhydride xylene solution, then add the above-mentioned treated carbon nanotubes into it and sonicate for 10min, under nitrogen protection, at 110°C, microwave The power is 300W, after reacting for 40min, filter while hot, and wash with xylene, acetone, ethanol, distilled water for 4 times, and then vacuum dry at 80°C for 8h to complete the functionalization of carbon nanotubes. . To obtain the product of maleic anhydride grafted on plasma-activated carbon nanotubes.

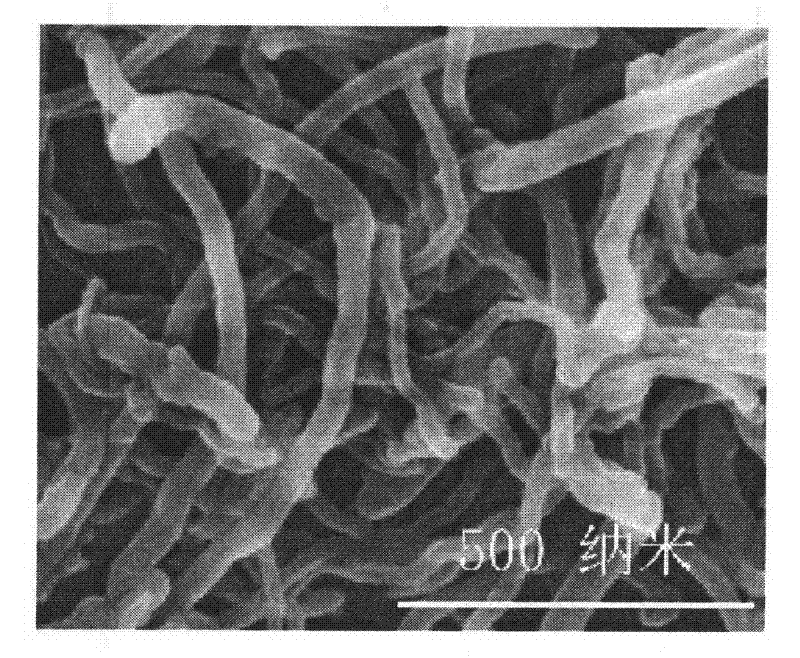

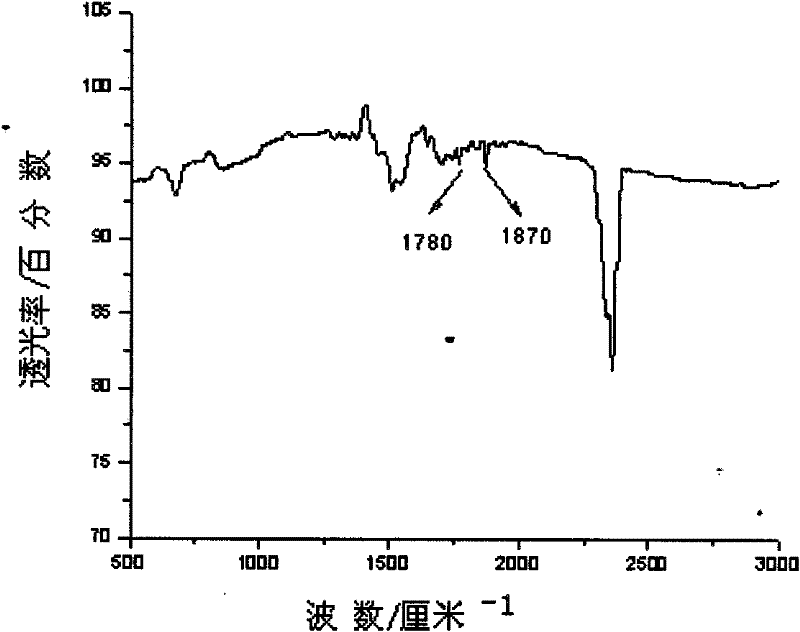

[0035] figure 1 It is a scanning electron micro...

Embodiment 2

[0041] In the step (2) of embodiment 1, maleic anhydride amount is 4.0g, and other conditions and steps are identical with embodiment 1, and the grafting rate of gained product is 8.2%.

Embodiment 3

[0043] In the step (3) of embodiment 1, microwave power is 200W, and other conditions and steps are identical with embodiment 1, and the graft rate of gained product is 9.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com