A kind of modified carbon fiber, preparation method and application

A technology for modifying carbon and carbon fiber, which is applied in shielding materials, magnetic field/electric field shielding, electrical components, etc. It can solve problems such as easy agglomeration and poor dispersion, and achieve the effects of enhancing roughness, improving electrical conductivity, and improving interface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

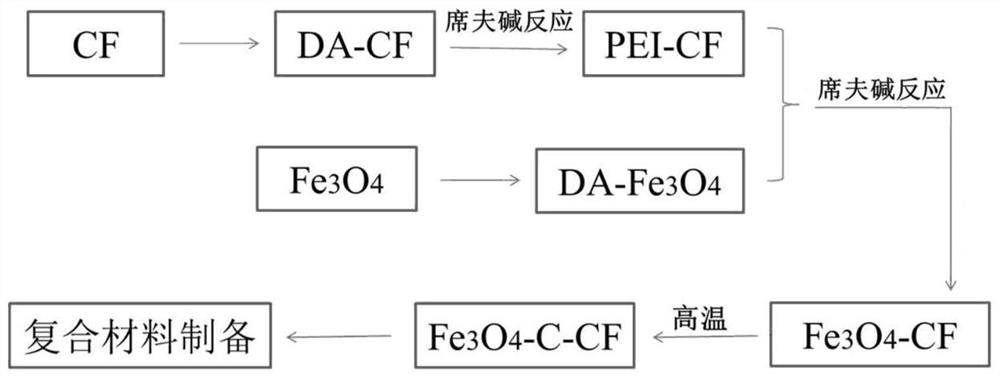

[0056] The present invention also provides a kind of preparation method of modified carbon fiber, comprises the following steps:

[0057] a) Immersing dopamine-modified carbon fibers into a solution containing substance A to obtain substance A-dopamine-modified carbon fibers;

[0058] The substance A is a compound or polymer containing an active amino group;

[0059] b) under alkaline conditions, the substance A-dopamine-modified carbon fiber and dopamine-modified filler are mixed and reacted in the liquid phase to obtain filler-modified carbon fiber;

[0060] The dopamine-modified filler includes dopamine-modified magnetic particles and / or dopamine-modified carbon nanomaterials;

[0061] c) Carbonizing the filler-modified carbon fibers to obtain modified carbon fibers.

[0062] In the modified carbon fiber preparation method provided by the present invention, firstly provide dopamine modified carbon fiber, the dopamine modified carbon fiber is composed of carbon fiber mater...

Embodiment 1

[0088] according to figure 1 The process shown in the preparation of composite materials specifically includes the following steps:

[0089] (1) Add dopamine (DA) into the Tris-HCl buffer solution with a pH value of 8.5 to prepare a DA / Tris-HCl buffer solution with a DA concentration of 1 mg / mL and stir evenly; then the desized carbon fiber fabric (CF ) immersed in DA / Tris-HCl buffer solution at room temperature for 12 hours; then washed three times with deionized water and dried at 80-100°C to prepare dopamine-modified carbon fibers (DA-CF).

[0090] (2) Add DA-CF to 1 mg / mL polyethyleneimine solution, and immerse at room temperature for 2 hours to obtain polyethyleneimine-modified carbon fiber (PEI-CF).

[0091] (3) Dopamine (DA) is added to the Tris-HCl buffer solution with a pH value of 8.5 to prepare a DA / Tris-HCl buffer solution with a DA concentration of 1 mg / mL and stir evenly; then ferric iron tetroxide nanoparticles Add to DA / Tris-HCl buffer at room temperature to ...

Embodiment 2

[0096] (1) Add dopamine (DA) into the Tris-HCl buffer solution with a pH value of 8.5 to prepare a DA / Tris-HCl buffer solution with a DA concentration of 2 mg / mL and stir evenly; then the desized carbon fiber fabric (CF ) immersed in DA / Tris-HCl buffer solution at room temperature for 24-36h; then washed three times with deionized water and dried at 80-100°C to prepare dopamine-modified carbon fibers (DA-CF).

[0097] (2) Add DA-CF to 2 mg / mL polyethyleneimine solution, and soak at room temperature for 1-2h to obtain polyethyleneimine-modified carbon fiber (PEI-CF).

[0098] (3) Dopamine (DA) is added to the Tris-HCl buffer solution with a pH value of 8.5 to prepare a DA / Tris-HCl buffer solution with a DA concentration of 2 mg / mL and stir evenly; Add it to DA / Tris-HCl buffer solution to prepare a mixed solution with a Ni concentration of 1 mg / mL, ultrasonicate at 200 W for 60 minutes, then magnetically stir the mixed solution at room temperature for 24 hours; finally wash with...

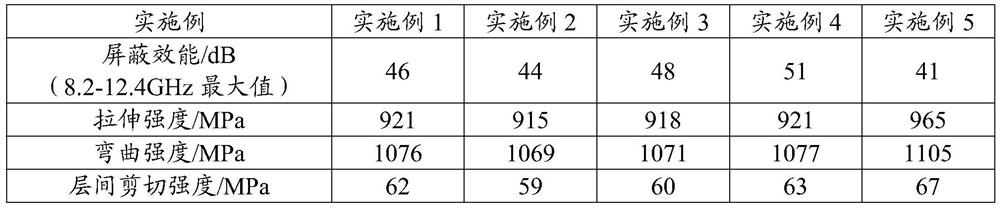

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com