Thermal regeneration device and method for ammonium bisulfate poisoning denitration catalyst

A technology of denitrification catalyst and ammonium bisulfate, which is applied in the thermal regeneration device field of denitrification catalyst poisoned by ammonium bisulfate, can solve the problems of lack of timely and reliable methods and large investment in the completion of regeneration technology evaluation, and achieve intelligent control of heating time and economy Good and universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

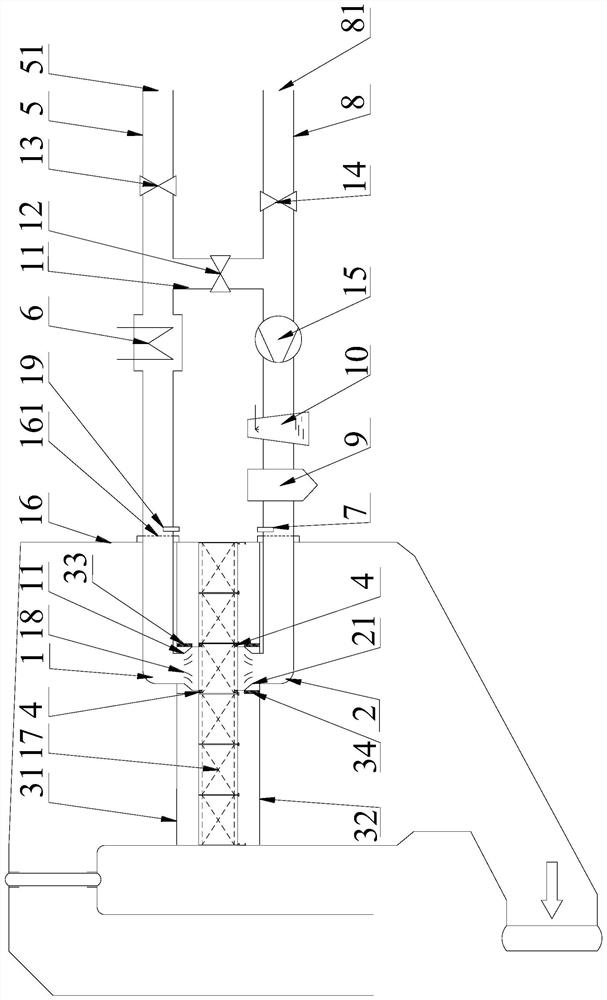

[0036] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

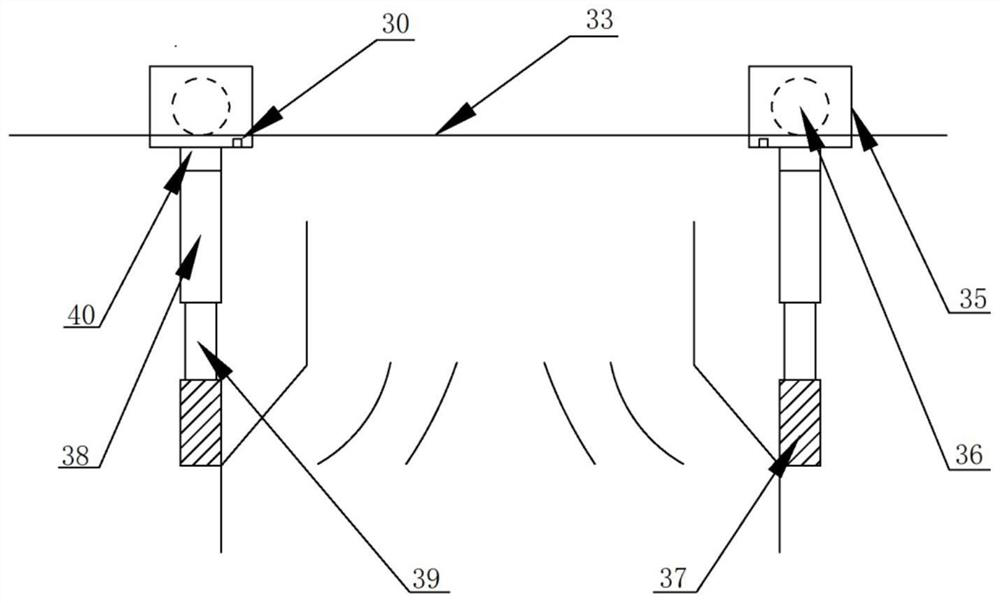

[0037] see Figure 1 to Figure 3 The thermal regeneration device of ammonium bisulfate poisoned denitrification catalyst, the device includes a thermal regeneration medium supply unit, a first thermal regeneration reaction unit 1, a second thermal regeneration reaction unit 2 and an ammonia concentration detection unit 7, and the thermal regeneration medium supply unit is used For the supply of heat regeneration medium, the heat regeneration medium is air, nitrogen, argon, and its temperature is 300-500°C, which has no pollution to the environment and meets environmental protection and safety.

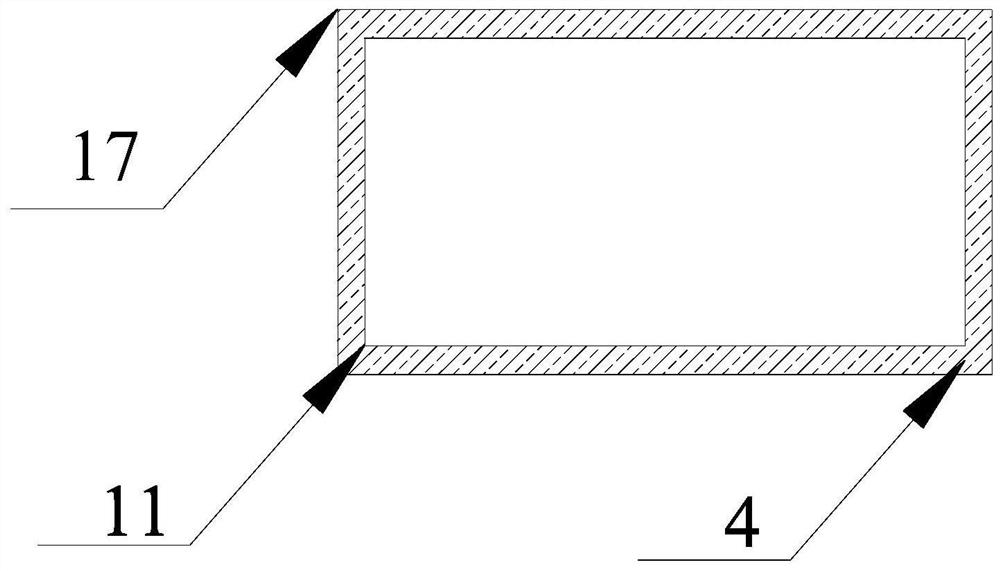

[0038] The specific structures of the first heat regeneration reaction unit 1 and the second heat regeneration reaction unit 2 are as follows: the first heat regeneration reaction unit 1 and the second heat regeneration reaction unit 2 are independent o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com