Method for preparing metal nanowire array on the basis of interface reaction and solid-state phase change

A metal nanowire, solid-state phase transition technology, applied in the field of preparation of metal nanowire arrays, can solve the problems of low efficiency, high cost, complex preparation process of metal nanowire arrays, etc., and achieves easy collection, less aggregation, and universality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

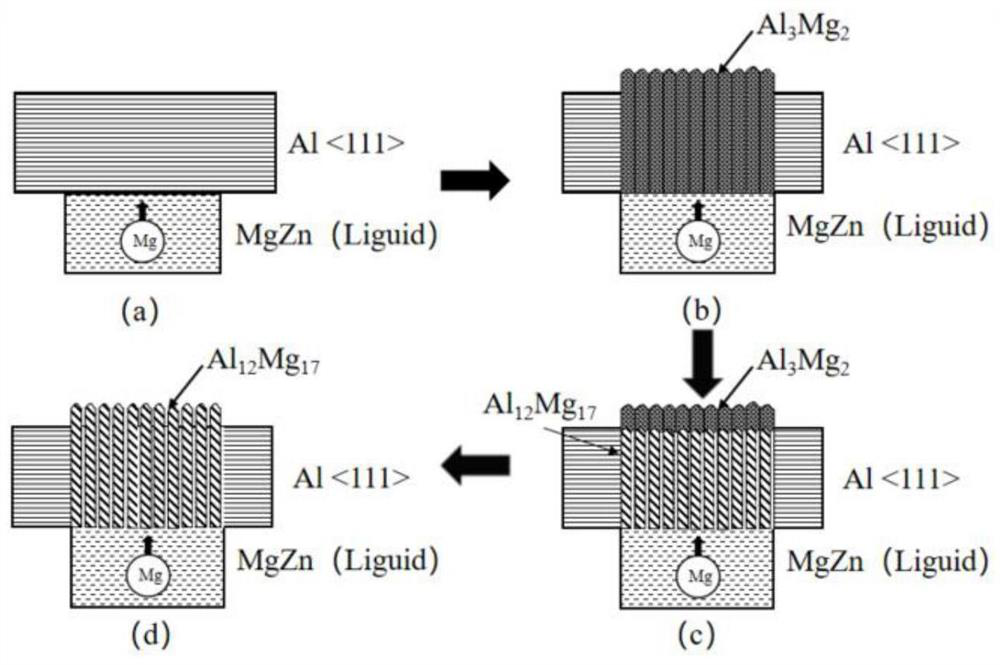

[0055] In specific implementation process, Al of the present invention 12 Mg 17 The preparation method of the nanowire array, firstly, the aluminum alloy substrate is cleaned; secondly, the MgZn-based alloy is used as the cladding material to make close contact with the substrate; thirdly, the metal nanowire array is grown on the aluminum alloy substrate by the method of reaction diffusion Inside; finally, remove the bulge on the surface of the substrate. The method specifically includes the following steps:

[0056] 1. Clean the surface of the substrate;

[0057] 2. Using MgZn-based alloy as the cladding material, the MgZn-based alloy is in close contact with the substrate as a diffusion couple to establish a reaction-diffusion system;

[0058] 3. Using the method of constant temperature heating, the growth of the intermetallic compound and the solid-state phase transition process are carried out in the reaction diffusion system established in step 2, and the growth direct...

Embodiment 1

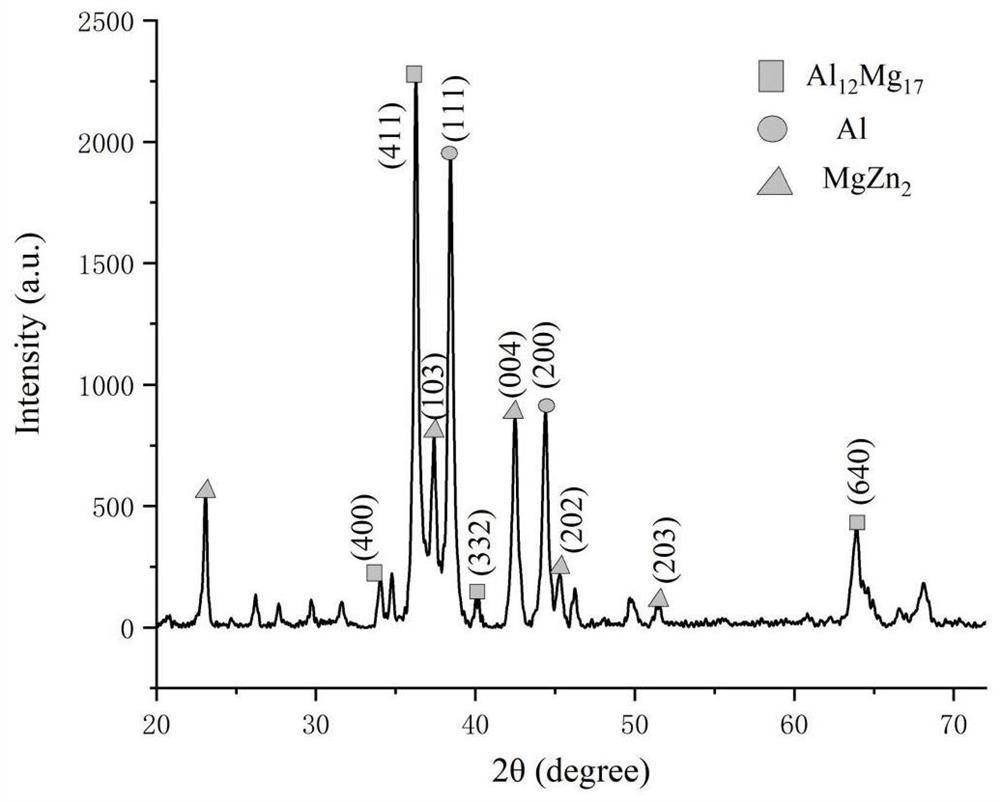

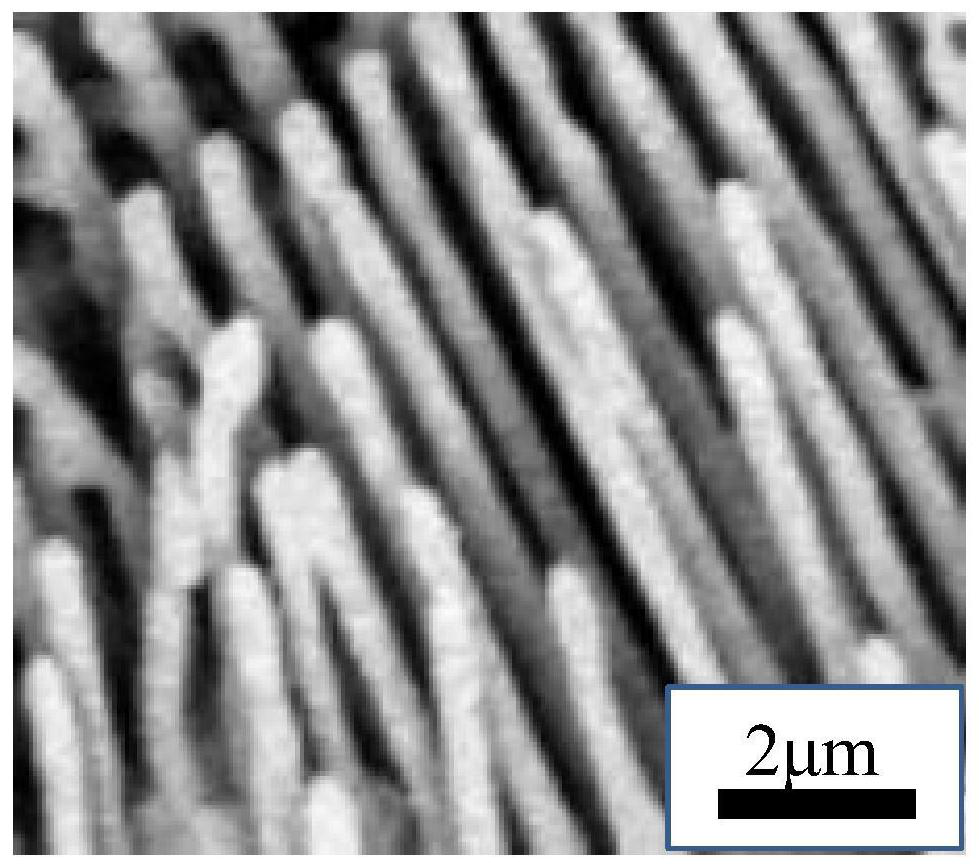

[0062] In this example, the preparation of Al 12 Mg 17 Nanowire array: use ethanol to clean the aluminum substrate in an ultrasonic cleaning machine, and the cleaning time is 5 minutes. The MgZn alloy is melted as the cladding material, and it is closely contacted with the metal Al plate by hot cladding. After the contact, the MgZn cladding layer and the metal Al plate are integrated as a diffusion couple, and the covering agent is used as a protective measure for solid-state During the phase transition process, the temperature is 450°C and the time is 5 minutes. Take out the diffusion couple after the reaction is completed, and use sandpaper grinding method for mechanical processing. After removing the bulge on the surface of the metal Al plate, the directional growth of Al can be obtained. 12 Mg 17 The technical parameters and performance indexes of the nanowire array are as follows: the wire diameter is 150-200nm, the spacing is 200-300nm, and the length is 4-6μm.

[00...

Embodiment 2

[0067] In this example, the preparation of Al 12 Mg 17 Nanowire array: use ethanol to clean the aluminum substrate in an ultrasonic cleaning machine, and the cleaning time is 5 minutes. A highly eutectic MgZn alloy is smelted as cladding material, and it is closely contacted with the metal Al plate by hot cladding. After contact, the MgZn cladding layer and the metal Al plate are integrated as a diffusion couple to cover As a protective measure, the solid-state phase transition process is carried out at a temperature of 460°C and a time of 5 minutes. Take out the diffusion couple after the reaction is completed, and use sandpaper grinding method for mechanical processing. After removing the bulge on the surface of the metal Al plate, the directional growth of Al can be obtained. 12 Mg 17 The technical parameters and performance indexes of the nanowire array are as follows: the wire diameter is 150-200nm, the spacing is 200-300nm, and the length is 4-6μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com