Plastic particle recycling system

A recovery system and plastic granule technology, applied in the field of plastic granule recovery system, can solve the problems of poor drying uniformity, affecting drying speed, low recovery efficiency, etc., and achieve the goal of accelerating drying, improving recovery efficiency, increasing gas production speed and gas production volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

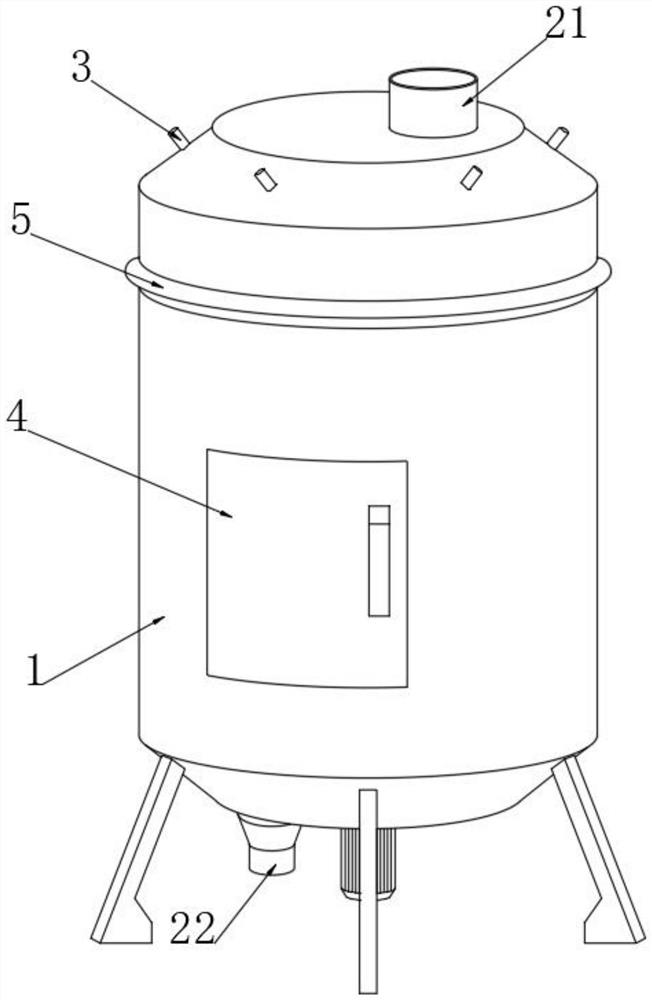

[0039] see figure 1 , a plastic particle recovery system, including particle conveying equipment, cleaning equipment, and drying and recycling equipment, the drying and recycling equipment includes a drying outer cylinder 1 with a heating component, the outer end of the drying outer cylinder 1 is connected with a sealed door 4, and the drying outer cylinder The upper end of the cylinder 1 is fixedly connected with a feed pipe 21 and a plurality of exhaust ports 3 , and the lower end of the drying outer cylinder 1 is fixedly connected with a discharge pipe 22 .

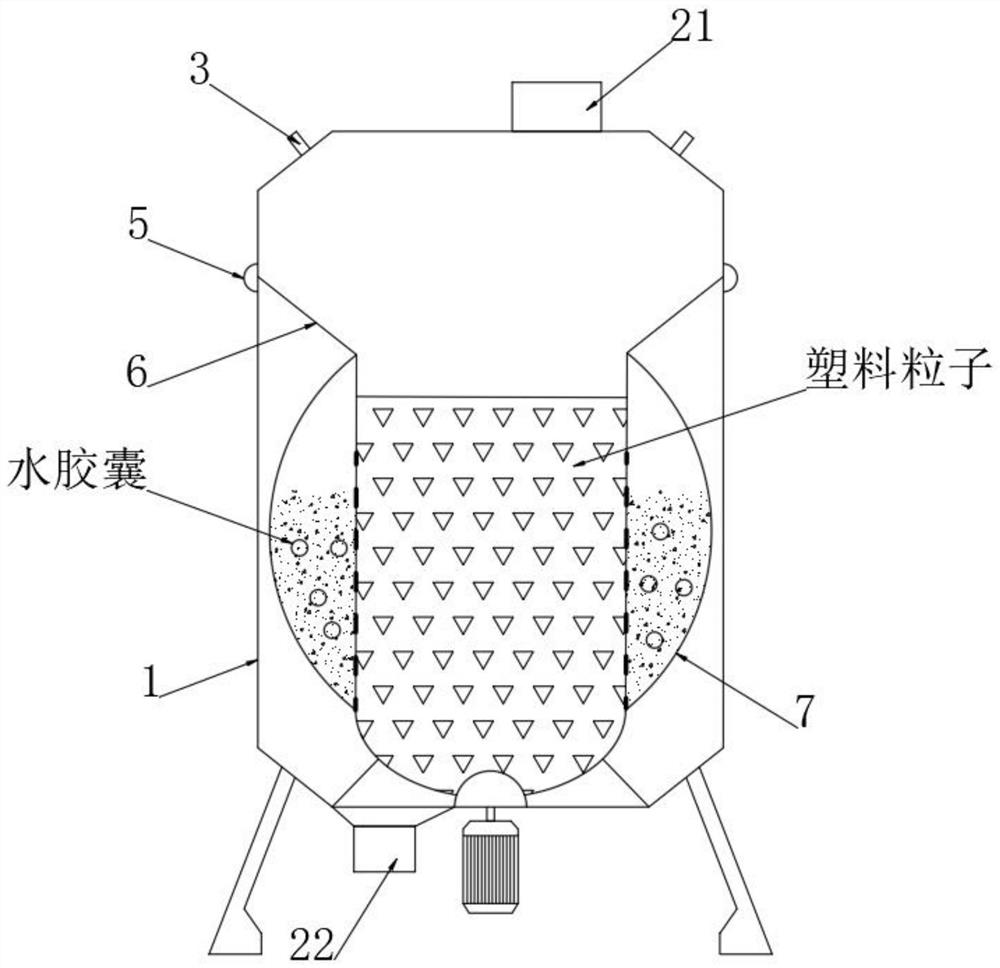

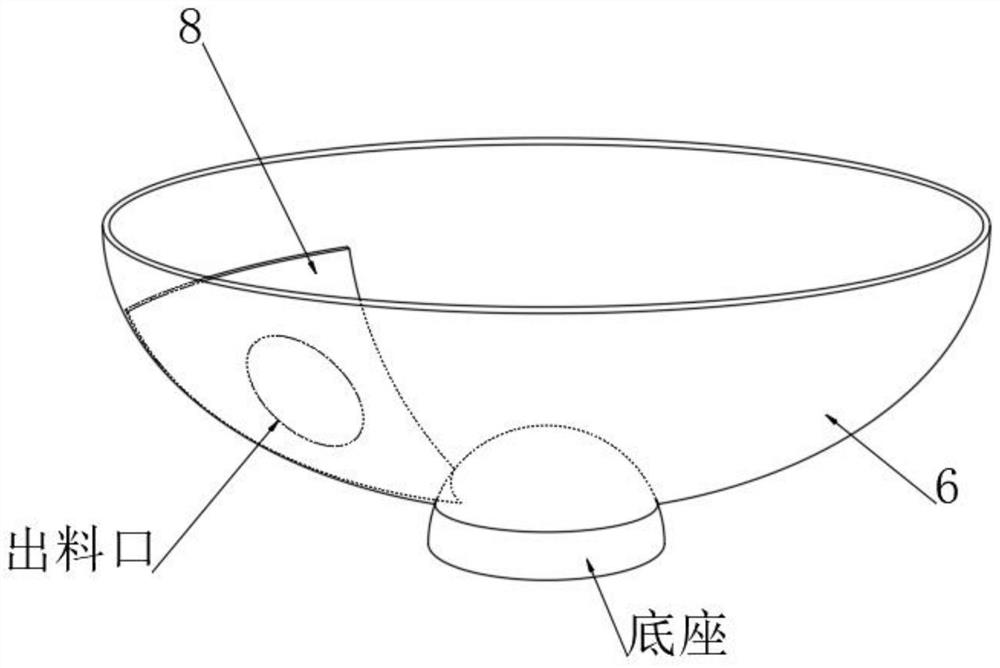

[0040] see Figure 2-3 , the outer end of the drying outer cylinder 1 is fixedly connected with an outer drum ring 5, the outer drum ring 5 is rotatably connected with an inner drying cylinder 6, the inner bottom of the drying outer cylinder 1 is provided with a base connected by a motor, and the upper end of the base is connected with the inner drying cylinder. The lower end of the cylinder 6 is fixedly connected, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com