Novel MXene metal nano composite material, preparation method and application

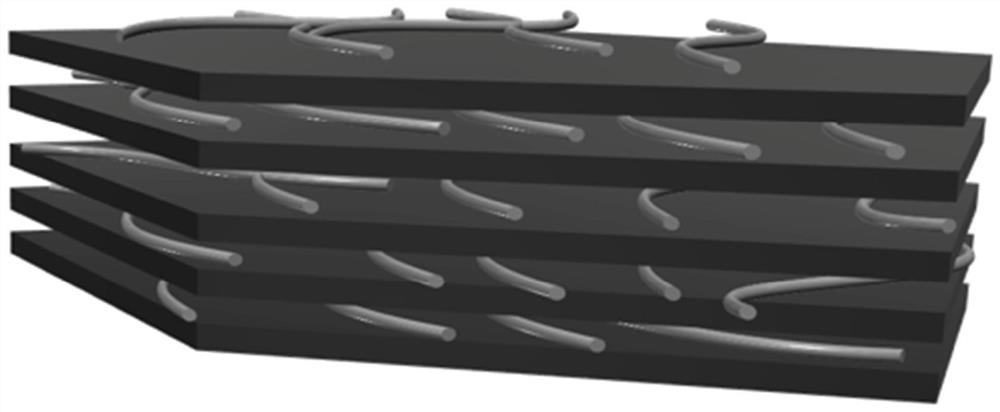

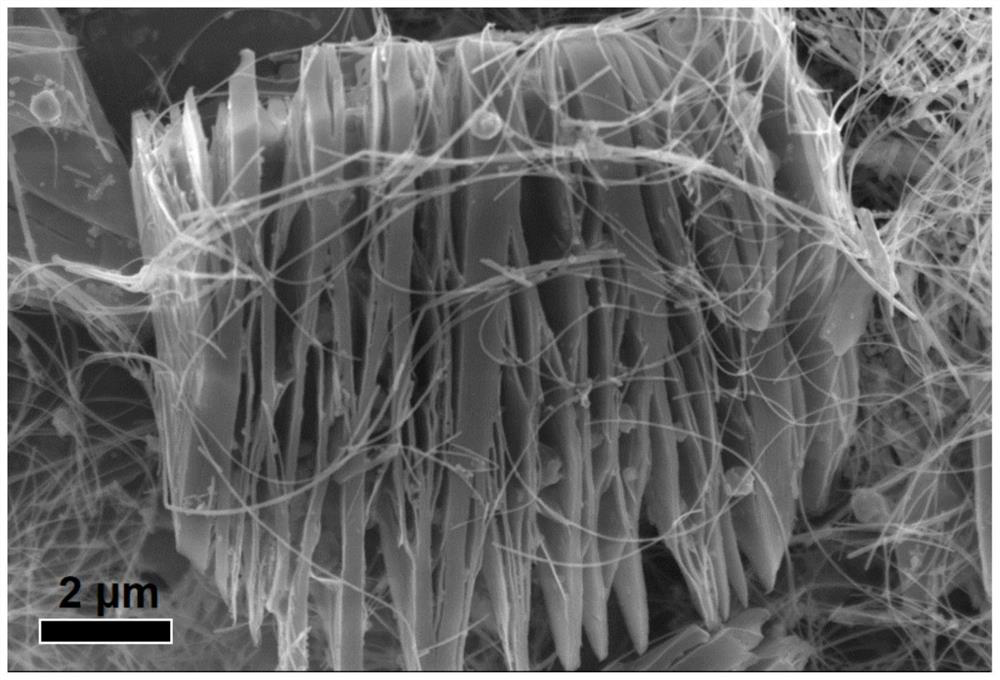

A technology of metal nano and composite materials, which is applied in the field of MXene materials, can solve the problems of reduced active sites, interlayer collapse, and lack of interlayer energy storage space, so as to achieve interlayer energy storage space, avoid collapse, and improve conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

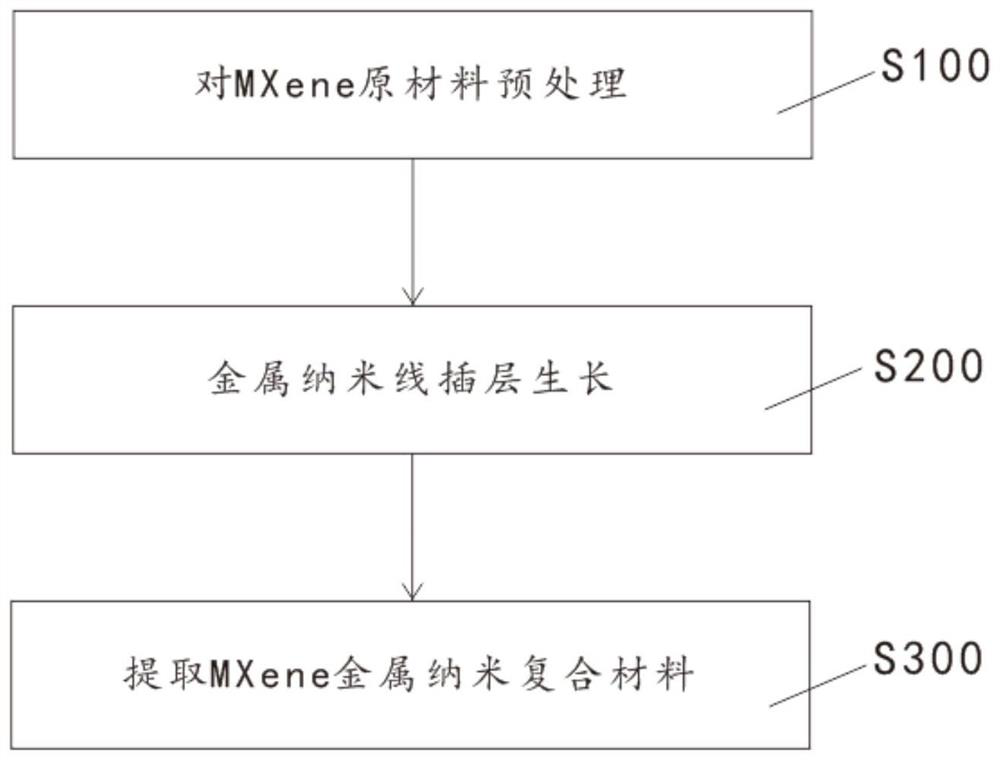

[0046] Take 0.1g of the MXene raw material and place it in a three-necked flask, add 5ml of structure-directing agent, and place the entire flask in cold water for mixed ultrasonic pretreatment; in this example, the MXene raw material is Ti 3 C 2 T x , the structure directing agent uses oleylamine, and the ultrasonic treatment time is 20min, so that oleylamine can fully infiltrate the Ti 3 C 2 T x ;

[0047] Next, in the mixture after pretreatment, add metal precursor and reducing agent, in this embodiment, add 0.1g cupric chloride as metal precursor and 0.1g nickel acetylacetonate as reducing agent, then place the three-necked flask in a magnetic Stirring platform, continuously feed nitrogen into it and add magnets, then raise the temperature to 180°C, stir and react for 4 hours, and make the mixture in the three-necked flask react, that is, copper chloride and Ti 3 C 2 T x A reaction occurs, and positively charged metal ions are adsorbed and inserted into the interlay...

Embodiment 2

[0050] Take 0.1g of MXene raw material and place it in a three-necked flask, add 10ml structure directing agent, place the whole flask in cold water for mixed ultrasonic pretreatment; in this example, the MXene raw material is Ti 2 CT x , the structure directing agent uses oleylamine, and the ultrasonic treatment time is 30min, so that oleylamine can fully infiltrate the Ti 2 CT x ;

[0051] Next, in the mixture after pretreatment, add metal precursor and reducing agent, in the present embodiment, add 0.1g cupric chloride as metal precursor and 0.15g nickel acetylacetonate as reducing agent, then place the three-necked flask in a magnetic Stirring table, continue to pass helium into it and add magnetons, then raise the temperature to 180 ° C, stir for 4 hours, and make the mixture in the three-necked flask react, that is, copper chloride and Ti 2 CT x A reaction occurs, and positively charged metal ions are adsorbed and inserted into the interlayer of MXene, and metal nano...

Embodiment 3

[0054] Take 0.1g of MXene raw material and place it in a three-necked flask, add 20ml structure directing agent, place the whole flask in cold water for mixed ultrasonic pretreatment; in this example, the MXene raw material is Ti 2 NT x , the structure directing agent uses oleylamine, and the ultrasonic treatment time is 40min, so that oleylamine can fully infiltrate the Ti 2 NT x ;

[0055] Next, in the mixture after pretreatment, add metal precursor and reducing agent, in the present embodiment, add 0.1g cupric chloride as metal precursor and 0.2g nickel acetylacetonate as reducing agent, then place the three-necked flask in a magnetic Stirring platform, continuously pass argon gas into it and add magnetons, then raise the temperature to 180°C, stir and react for 4h, and make the mixture in the three-necked flask react, that is, copper chloride and Ti 2 NT x A reaction occurs, and positively charged metal ions are adsorbed and inserted into the interlayer of MXene, and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com