Preparation method of phase change gel material with variable mechanical state

A technology of mechanical state and gel material, which is applied in the field of phase change materials, can solve the problems of complex operation and high cost, and achieve the effect of simple operation, low cost, and improved temperature regulation and temperature control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In a first aspect, the application provides a method for preparing a phase-change gel material with a variable mechanical state, which includes the following steps:

[0038] (1) Using the initiator / tetramethylethylenediamine oxidation-reduction system as the initiating system, prepare a poly-N-isopropylacrylamide hydrogel with a three-dimensional crosslinked network structure, and then soak it in a lower alcohol for alcoholization to obtain alcohol gel; and

[0039] (2) heating and melting the phase change material to perform solvent replacement with the alcohol gel to obtain the phase change gel material.

[0040] In this application, an easy-to-implement, novel and low-cost preparation method for three-dimensional cross-linked gel-supported phase-change gel materials is proposed. Wherein, the phase change gel material has a three-dimensional cross-linked network gel as a supporting frame, which can prevent the contained phase change material from leaking, and can mai...

Embodiment 1

[0068] According to the preparation method of the phase-change gel material of variable mechanical state of the present application, it comprises the following steps:

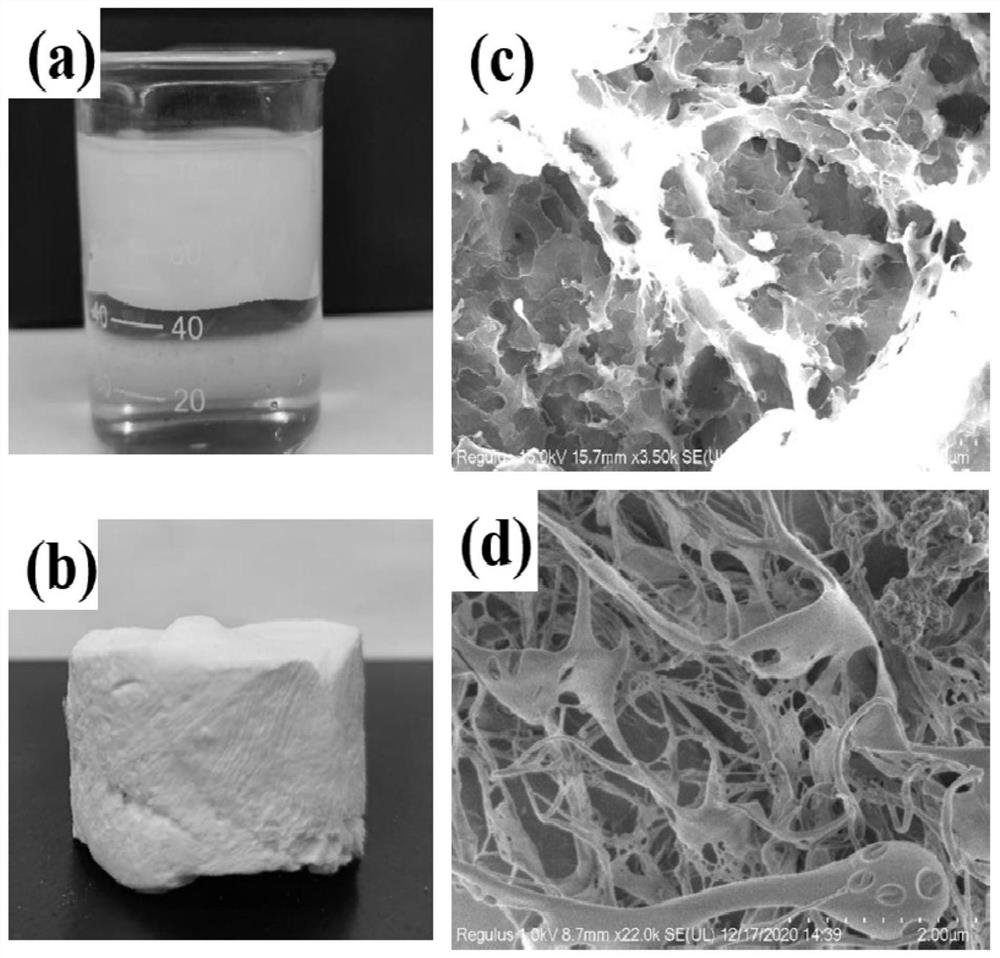

[0069] (1) Dissolve 2.3g of N-isopropylacrylamide, 0.069g of methylenebisacrylamide and 0.023g of initiator potassium persulfate in 10mL of deionized water, and in a nitrogen atmosphere, at 25°C Stir in an oil bath for 30 min. Subsequently, 20 μL of tetramethylethylenediamine was added thereto, and the system was isolated from air, and heated and reacted in an oil bath at 50° C. for 30 minutes. When the temperature drops to room temperature, pour acetone and soak for 12 hours, then soak in deionized water for 12 hours, and finally soak in ethanol for 24 hours to fully alcoholize to obtain alcohol gel;

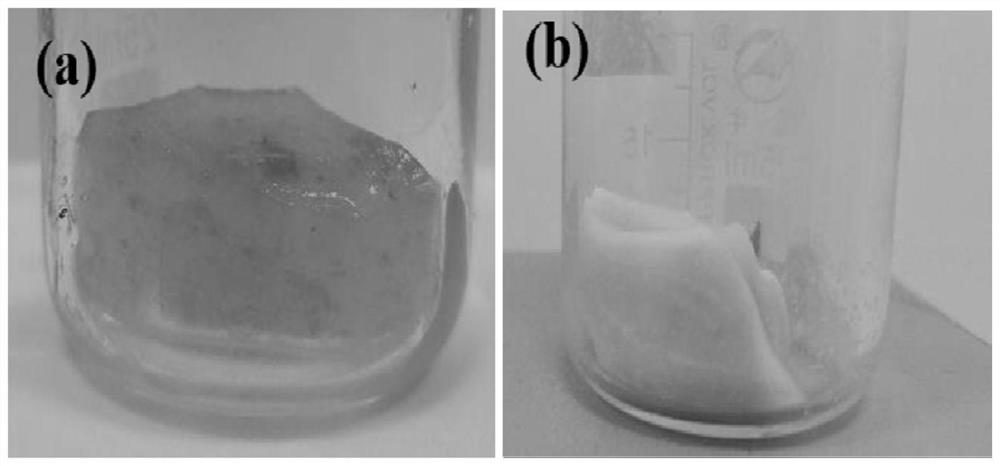

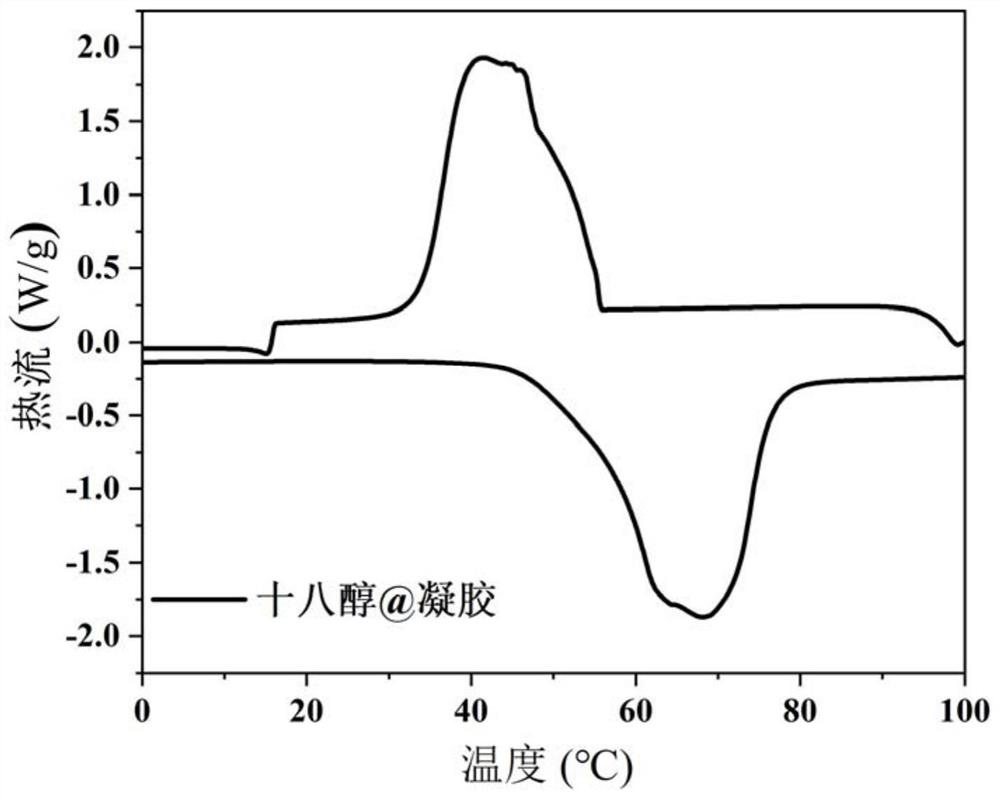

[0070] (2) Heating 2g of the phase change material stearyl alcohol at 80°C until completely melted, adding 0.66g of the alcohol gel into the above stearyl alcohol melt, and incubating at 80°C for 12h to perform...

Embodiment 2

[0075] According to the preparation method of the phase-change gel material of variable mechanical state of the present application, it comprises the following steps:

[0076] (1) Dissolve 1.8g of N-isopropylacrylamide, 0.072g of methylene bisacrylamide and 0.018g of initiator potassium persulfate in 10mL of deionized water, and in a nitrogen atmosphere, at 25°C Stir in an oil bath for 30 min. Subsequently, 10 μL of tetramethylethylenediamine was added thereto, the system was isolated from air, and heated and reacted in an oil bath at 50° C. for 30 minutes. When the temperature drops to room temperature, pour acetone and soak for 12 hours, then soak in deionized water for 12 hours, and finally soak in ethanol for 24 hours to fully alcoholize to obtain alcohol gel; further replace ethanol with dichloromethane.

[0077] (2) Heating 2g of the phase change material hexadecane at 80°C until completely melted, adding 0.66g of the alcohol gel to the above hexadecane melt, and keepin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com