Preparation method of poly (aryl ether ketone) and poly (aryl ether ketone)

A technology of aryl ether ketone and benzophenone, applied in the field of polymer materials, can solve the problems of dark color, poor product quality and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a kind of preparation method of poly(aryl ether ketone), the method comprises:

[0021] Step 1: Mix benzophenone compounds or diacid chloride compounds, hydroxyl-containing compounds and sodium borohydride uniformly under the action of the first solvent, and heat to 80-150° C. to remove the first solvent to obtain a premix;

[0022] Step 2: Using the premix obtained in Step 1 as the reaction substrate, adding the second solvent and carbonate in sequence at 150-160° C., and gradually raising the temperature for reaction to obtain poly(aryl ether ketone).

[0023] According to the present invention, first add benzophenone compounds or diacid chloride compounds, hydroxyl-containing compounds, sodium borohydride and the first solvent in the three-necked flask in sequence, start slowly and stir to 30-40rpm, and after 5-10 minutes, the solids Dissolve everything, increase the stirring speed to 100-120rpm, stir for 10-15 minutes, mix the reaction materia...

Embodiment 1

[0036] Take a 3000ml three-necked bottle and place it in a heating mantle, insert a metal stirring paddle into the middle port of the three-necked bottle, weigh 218.2g (1mol) of 4,4'-difluorobenzophenone into the three-necked bottle from one port, and weigh 110.1 g (1mol) of hydroquinone was added into the three-necked bottle from the same side port, and 1.892g sodium borohydride (0.05mol) was added into the three-necked bottle from the same side port, and 800ml of acetone was measured, Add it into the three-necked flask, start stirring slowly to 30rpm, and after 5 minutes all the solids are dissolved, increase the stirring speed to 100rpm, and stir for 10 minutes, and the 4,4'-difluorobenzophenone and hydroquinone are thoroughly mixed. Seal the feeding edge of the three-necked bottle, connect the other side (collecting the edge) to a straight condenser tube and a collecting bottle, keep the stirring speed at 100 rpm, heat the three-necked bottle to 80°C, the acetone in the thr...

Embodiment 2

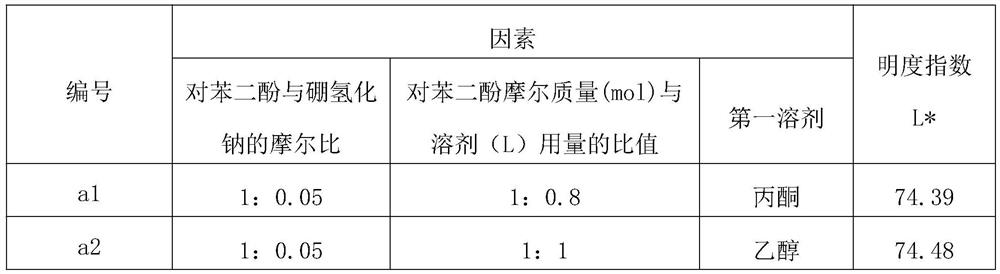

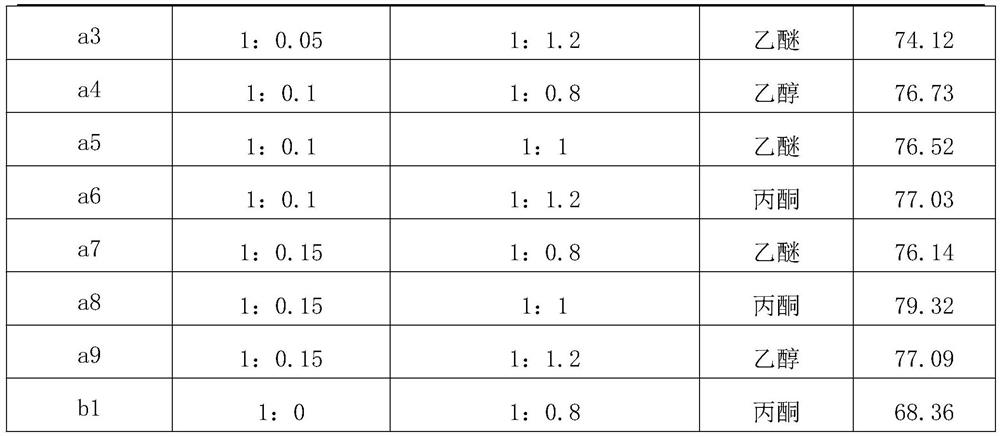

[0043] Prepare poly(aryl ether ketone) a2-a9 according to the steps of Example 1, the difference is that the type of the first solvent in step 1, the amount of the first solvent and the amount of sodium borohydride are changed, as shown in the table 1 shows:

[0044] Table 1

[0045]

[0046]

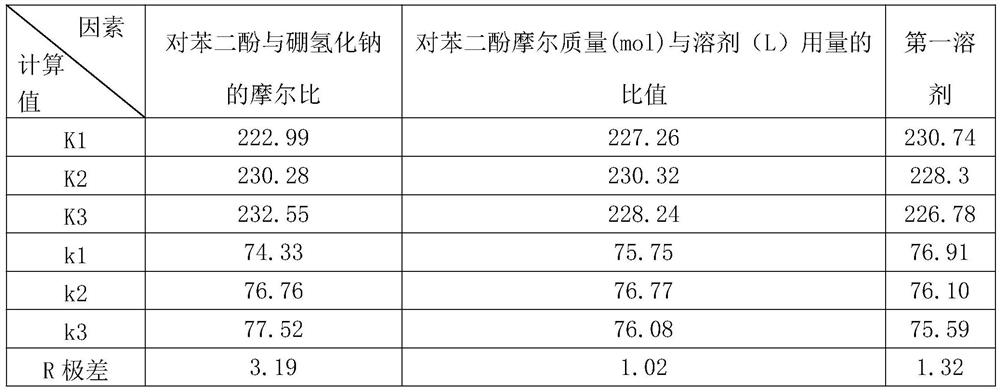

[0047] From this, the orthogonal factor influence table can be obtained, as shown in Table 2

[0048] Table 2

[0049]

[0050] As can be seen from Tables 1 and 2, the amount of sodium borohydride has the greatest impact on the premixing effect, and the order of impact is: the amount of sodium borohydride>the first solvent>the amount of solvent, so the best premixing condition is: using acetone as For solvent, the molar ratio of hydroquinone to sodium borohydride is 1:0.15, and the ratio of molar mass (mol) of hydroquinone to solvent (L) is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com