System and method for continuously and flexibly preparing methane by utilizing renewable energy sources

A renewable energy and energy storage system technology, applied in the direction of electric energy storage system, energy storage, energy input, etc., can solve the problems of inability to realize thermal integration of devices, increase the scale of process equipment, limit economic feasibility, etc., and achieve thermal Integrate and heat cycle, avoid volatility and intermittency, and improve the effect of energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

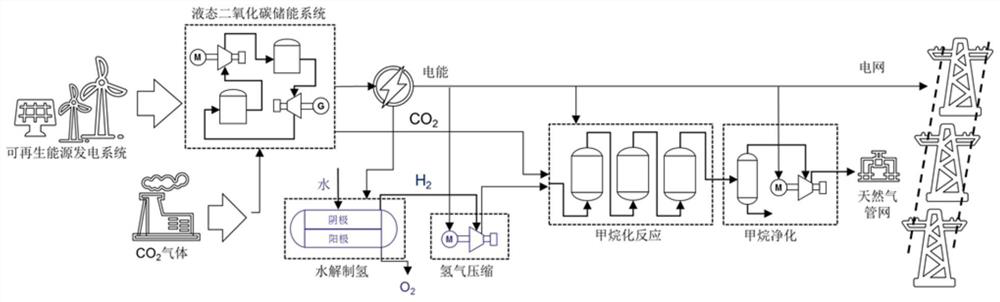

[0057] refer to figure 1 , the present invention provides a continuous and flexible system for producing methane from renewable energy sources, including renewable energy power generation systems, liquid CO 2 Energy storage system, methanation production system, the renewable energy power generation system and liquid CO 2 The energy storage system is connected and is liquid CO 2 The energy storage system provides electrical energy, the liquid CO 2 The energy storage system is connected to the methanation production system and provides CO for the methanation reaction 2 , the electrical energy required by the methanation production system consists of liquid CO 2 Energy storage system or grid power supply.

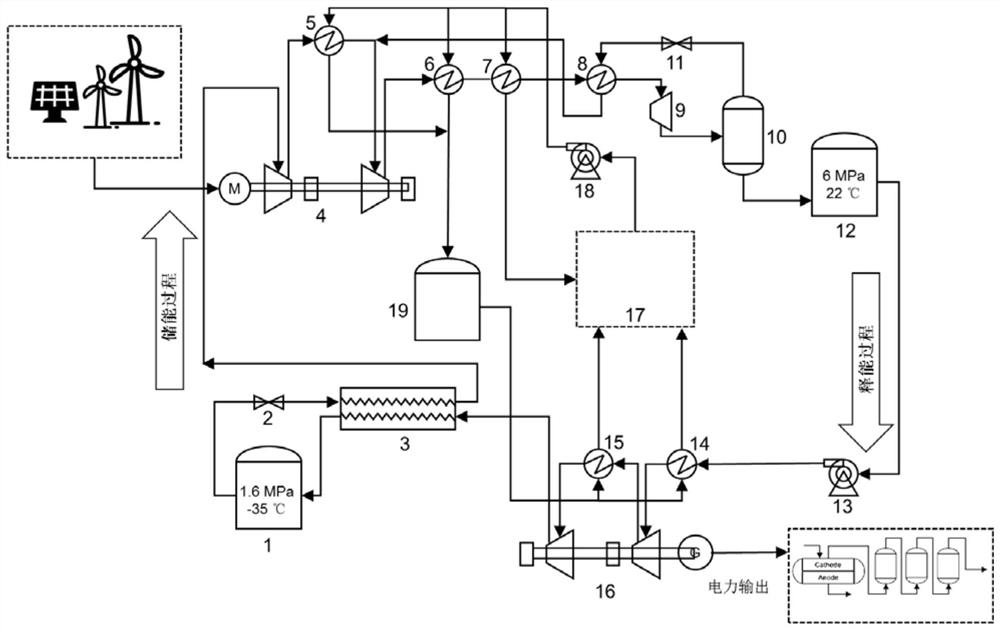

[0058] refer to figure 2 , the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com