Alloy element adding method for steel hot galvanizing

An alloy element, hot-dip galvanizing technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of shortening the smelting time of the intermediate alloy, easy burning of the metal element, difficult to melt into the high melting point, etc. , to shorten the smelting time, improve the metal yield, and achieve the effect of stable yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

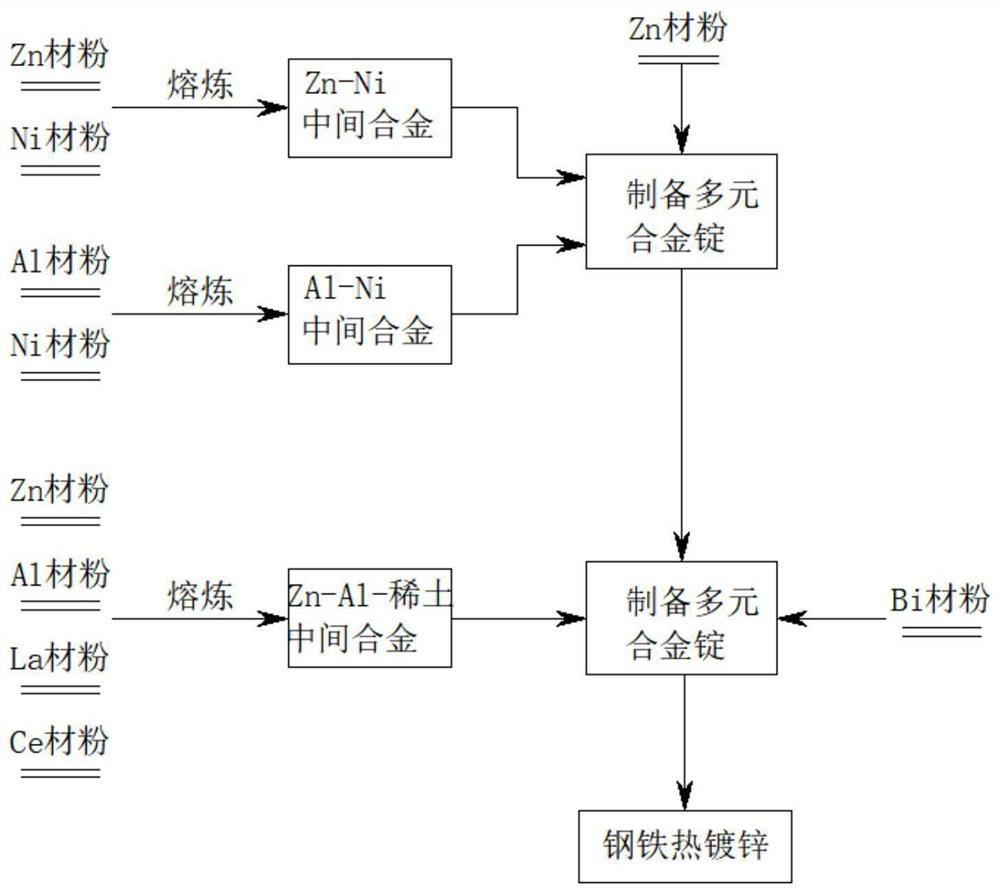

[0041] see figure 1 Shown, the present invention is a kind of method for adding alloy elements for hot-dip galvanizing of iron and steel, comprising the following steps (in terms of furnace capacity 1000kg):

[0042] S1: Grind Al, Ni, Bi, La, Ce and Zn in batches. The specifications of Bi and Zn are 80-100 mesh. Al, Ni, Mg, The crushing specifications of La material and Ce material are both 200-400 meshes. After crushing, 100kg of Al material powder, 10kg of Ni material powder, 15kg of Bi material powder, 5kg of La material powder, 5kg of Ce material powder and 865kg of Zn material powder, the mass percentage of the components of the multi-element alloy ingot is Al10±2%, Ni1±0.1%, Bi1.5±0.15%, La0.5%, Ce0.5%, and the rest are Zn;

[0043] S2: Smelting Zn-Ni master alloy;

[0044] The concrete steps of smelting Zn-Ni master alloy are:

[0045] S21: Add 100kg of Zn material powder into the intermediate frequency furnace and raise the temperature to 450°C;

[0046] S22: After...

Embodiment 2

[0065] see figure 1 Shown, the present invention is a kind of method for adding alloy elements for hot-dip galvanizing of iron and steel, comprising the following steps (in terms of furnace capacity 1000kg):

[0066] S1: Grind Al, Ni, Bi, La, Ce and Zn in batches. The specifications of Bi and Zn are 80-100 mesh. Al, Ni, Mg, The crushing specifications of La material and Ce material are both 200-400 meshes. After crushing, 100kg of Al material powder, 10kg of Ni material powder, 15kg of Bi material powder, 5kg of La material powder, 5kg of Ce material powder and 865kg of Zn material powder, the mass percentage of the components of the multi-element alloy ingot is Al10±2%, Ni1±0.1%, Bi1.5±0.15%, La0.5%, Ce0.5%, and the rest are Zn;

[0067] S2: Smelting Zn-Ni master alloy;

[0068] The concrete steps of smelting Zn-Ni master alloy are:

[0069] S21: Add 100kg of Zn material powder into the intermediate frequency furnace, and raise the temperature to 475°C;

[0070] S22: Afte...

Embodiment 3

[0089] see figure 1 Shown, the present invention is a kind of method for adding alloy elements for hot-dip galvanizing of iron and steel, comprising the following steps (in terms of furnace capacity 1000kg):

[0090] S1: Grind Al, Ni, Bi, La, Ce and Zn in batches. The specifications of Bi and Zn are 80-100 mesh. Al, Ni, Mg, The crushing specifications of La material and Ce material are both 200-400 meshes. After crushing, 100kg of Al material powder, 10kg of Ni material powder, 15kg of Bi material powder, 5kg of La material powder, 5kg of Ce material powder and 865kg of Zn material powder, the mass percentage of the components of the multi-element alloy ingot is Al10±2%, Ni1±0.1%, Bi1.5±0.15%, La0.5%, Ce0.5%, and the rest are Zn;

[0091] S2: Smelting Zn-Ni master alloy;

[0092] The concrete steps of smelting Zn-Ni master alloy are:

[0093] S21: Add 100kg of Zn material powder into the intermediate frequency furnace, and raise the temperature to 500°C;

[0094] S22: Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com