Ring dyeing method of cotton fibers

A cotton fiber and cotton fabric technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of denim retro style difficult to deal with, unable to meet denim dyeing requirements, etc., to achieve fast dyeing speed and color fixation efficiency High and efficient recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

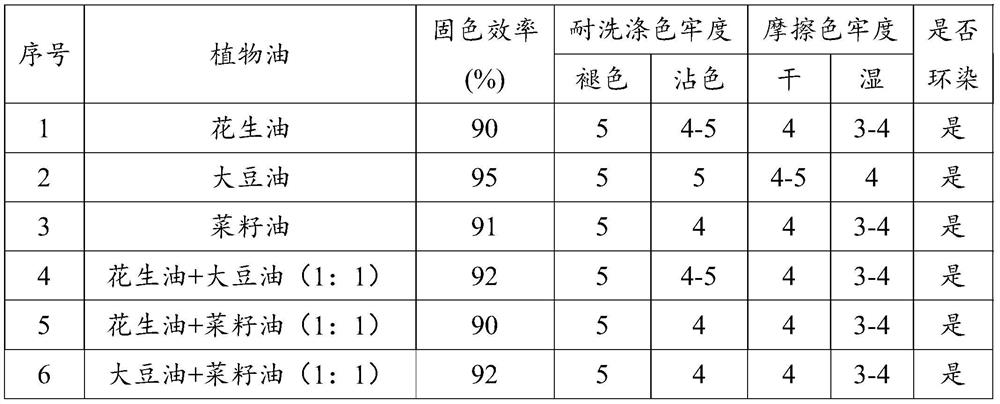

[0034] Cotton yarn is soaked in various vegetable oils, and then rolled on a padding machine so that it contains 80% oil carrying rate.

[0035] Add 5 g of sodium alginate to 95 g of water to prepare a 5% sodium alginate paste. Get 2g (2%) of reactive blue 194 dye, 3g (3%) of ethanol, 3g (3%) of sodium carbonate, 50g (50%) of sodium alginate paste with a mass fraction of 5%, 42g (42%) of water, mix After stirring, it is made into a spray dyeing slurry.

[0036] Tension is applied to the calendered cotton yarn containing vegetable oil, so that the cotton yarn is in a taut state. The prepared spray dyeing paste is added into the spray gun to spray dye the cotton yarn. After spraying, dry it in an oven, and then steam it in steam for 10 minutes. Then rinse most of the vegetable oil and floating color on the cotton yarn with running cold water, then wash in soap solution, wash in cold water, and dry to complete the dyeing.

[0037] The dyeing effect is characterized by the col...

Embodiment 2

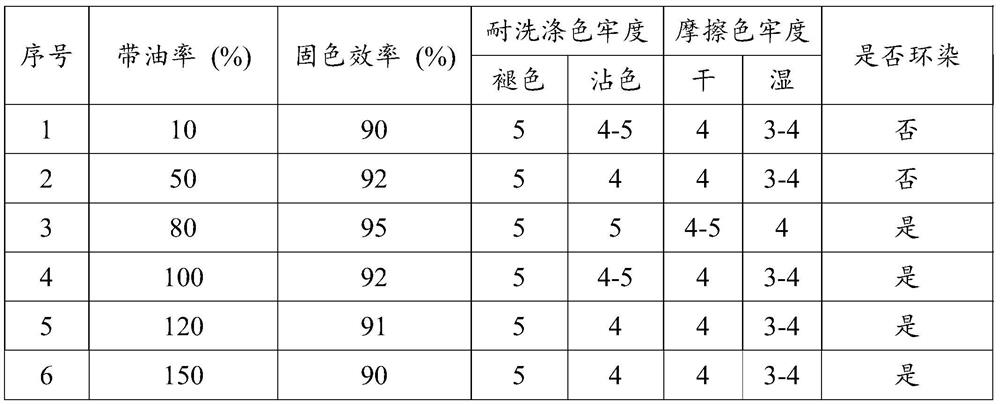

[0041] The cotton yarn is soaked in soybean vegetable oil, and then rolled on a padding car, so that it contains 10%-150% oil carrying rate.

[0042] Add 5 g of sodium alginate to 95 g of water to prepare a 5% sodium alginate paste. Get 2g (2%) of reactive blue 194 dye, 3g (3%) of ethanol, 3g (3%) of sodium carbonate, 50g (50%) of sodium alginate paste with a mass fraction of 5%, 42g (42%) of water, mix After stirring, it is made into a spray dyeing slurry.

[0043] Tension is applied to the calendered cotton yarn containing vegetable oil, so that the cotton yarn is in a taut state. The prepared spray dyeing paste is added into the spray gun to spray dye the cotton yarn. After spraying, dry it in an oven, and then steam it in steam for 10 minutes. Then rinse most of the vegetable oil and floating color on the cotton yarn with running cold water, then wash in soap solution, wash in cold water, and dry to complete the dyeing.

[0044] The dyeing effect is characterized by th...

Embodiment 3

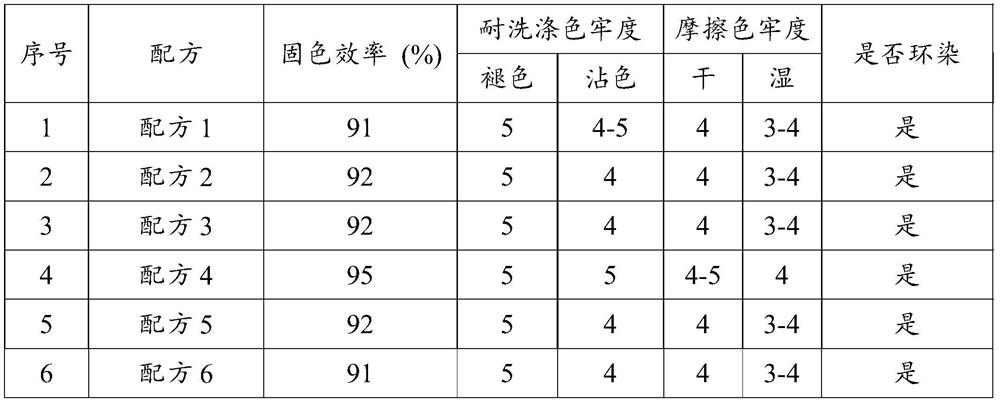

[0048]Cotton yarn is dipped in soybean vegetable oil, and then rolled on a padding machine so that it contains 80% oil carrying rate.

[0049] Add 5 g of sodium alginate to 95 g of water to prepare a 5% sodium alginate paste. Change the ratio of reactive blue 194 dye, ethanol, sodium carbonate, sodium alginate paste with a mass fraction of 5% and water (in Table 3) in the color paste, stir after mixing, and make a spray dyeing paste.

[0050] Tension is applied to the calendered cotton yarn containing vegetable oil, so that the cotton yarn is in a taut state. The prepared spray dyeing paste is added into the spray gun to spray dye the cotton yarn. After spraying, dry it in an oven, and then steam it in steam for 10 minutes. Then rinse most of the vegetable oil and floating color on the cotton yarn with running cold water, then wash in soap solution, wash in cold water, and dry to complete the dyeing.

[0051] The dyeing effect is characterized by the color fixing efficiency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com