A kind of preparation method of casting superalloy spectroscopic analysis internal control standard

A high-temperature alloy and spectral analysis technology, applied in the field of chemical analysis of high-temperature alloys, can solve the problem that it is difficult to prepare standard samples or internal control standard samples for high-temperature alloy spectral analysis, the accuracy and reliability of test results cannot be guaranteed, and it is difficult to control the uniformity of components In order to overcome the problems of uneven composition and uncontrollable defects, it is easy to realize and ensure the uniformity of composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

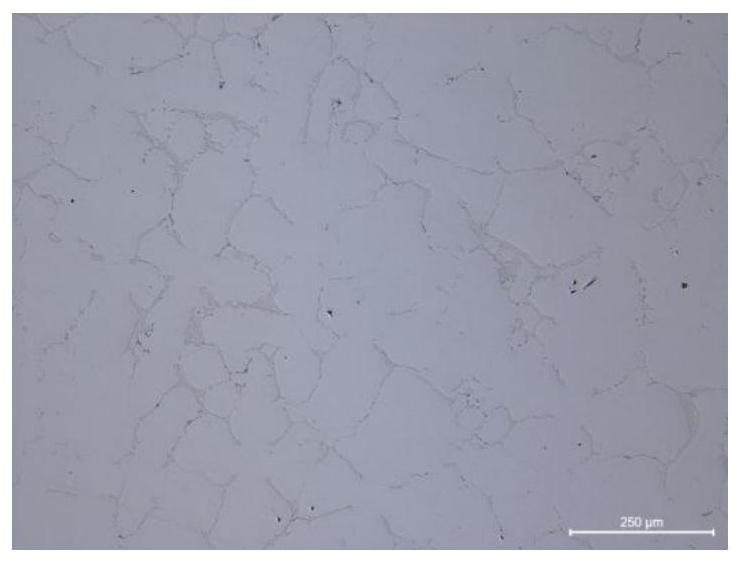

[0029] In the specific implementation process, the method for preparing an internal control standard sample for spectroscopic analysis of cast superalloys of the present invention mainly includes the following steps: (1) determining the alloy's batching point according to the element mass percentage range of the superalloy, and using a vacuum furnace for high-temperature melt treatment Then prepare a master alloy ingot; (2) use a directional solidification furnace to remelt the master alloy ingot to prepare a directional solidification sample, and process it into a sample of a certain size; (3) perform a homogenization heat treatment on the sample, Improve ingredient uniformity.

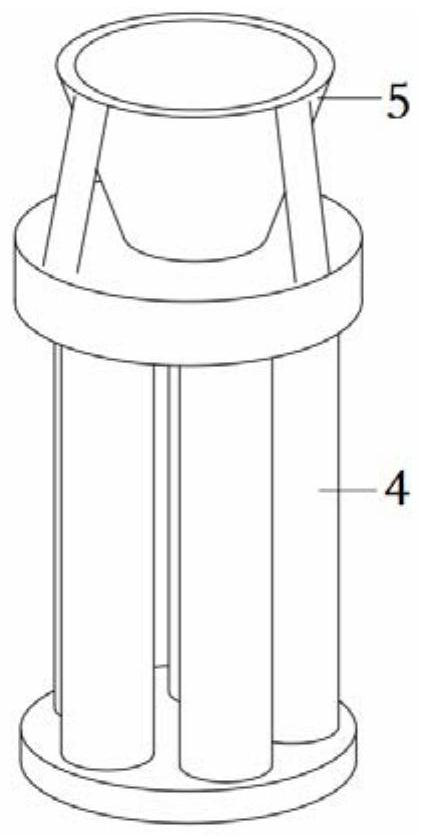

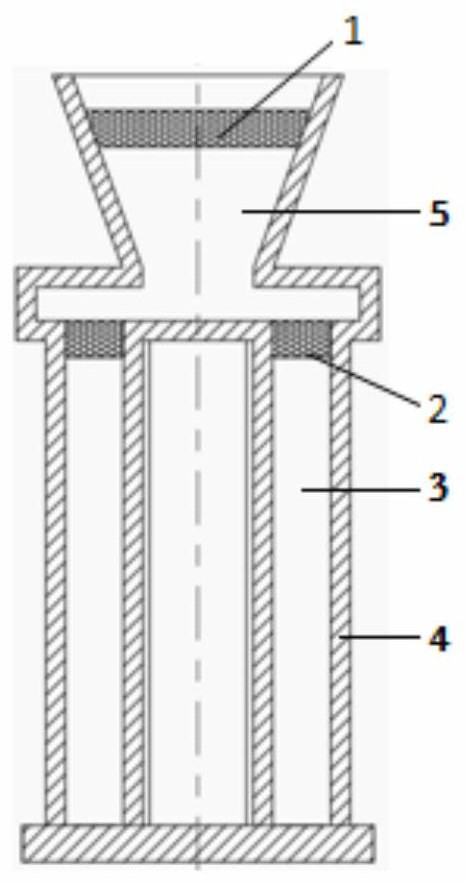

[0030] like figure 1 and figure 2 As shown, the top of the mold shell 4 is provided with a pouring cup 5, the mold shell 4 used in the directional solidification process can form seven cylindrical samples 3, and a first slag baffle plate 1 is horizontally provided at the pouring cup 5, Moreover, a...

Embodiment 1

[0033] In this embodiment, for the preparation method of the internal control standard sample for spectroscopic analysis of cast superalloy, the selected alloy is DZ417G, which is composed of the following components by mass percentage: C0.13%-0.22%, Cr8.5%-9.5%, Co9.00 %~11.00%, Mo2.50%~3.50%, Al4.80%~5.70%, Ti4.10%~4.70%, V0.60%~0.90%, B0.012%~0.024%, Ni is the balance. In terms of mass percentage, the following batching points of DZ417G samples prepared by this method: C0.19%, Cr9.1%, Co10.0%, Mo3.1%, Al5.42%, Ti4.45%, V0. 80%, B0.019%, Ni is the balance.

[0034] The method for preparing an internal control standard sample for spectroscopic analysis of a cast superalloy includes the following steps:

[0035] 1. Prepare alloy raw materials according to the composition range of the superalloy, add it into a 50kg vacuum induction furnace, process it with a high temperature melt (the temperature is selected to be higher than the liquidus line of the alloy and keep for 3-5min ...

Embodiment 2

[0040] In this embodiment, for the preparation method of the internal control standard sample for spectroscopic analysis of cast superalloy, the selected alloy is DZ40M, which is composed of the following components by mass percentage: C0.45%-0.55%, Cr24.5%-26.5%, Ni9.5 %~11.5%, W7.00%~8.00%, Mo0.10%~0.50%, Al0.7%~1.2%, Ti0.05%~0.30%, Ta0.10%~0.50%, B0.008%~ 0.018%, Zr 0.10% to 0.30%, Co is the balance. In terms of mass percentage, the following are the ingredients of DZ40M samples prepared by this method: C0.52%, Cr25.6%, Ni10.7%, W7.7%, Mo0.23%, Al1.0%, Ti0. 20%, Ta0.30%, B0.013%, Zr0.20%, Co is the balance.

[0041] The method for preparing an internal control standard sample for spectroscopic analysis of a cast superalloy includes the following steps:

[0042] 1. Prepare alloy raw materials according to the composition range of the superalloy, add it into a 50kg vacuum induction furnace, process it with a high temperature melt (the temperature is selected to be higher th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com