Solar module mounting structure

A technology for solar modules and installation structures, which is applied to the support structure of photovoltaic modules, electrical components, photovoltaic power generation, etc., can solve the problems of easy rusting of bolts, low disassembly and installation efficiency of solar photovoltaic panels, and difficulty in adjusting the installation angle of solar modules, etc. To achieve the effect of easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

[0037] The technical solution used in the present invention is:

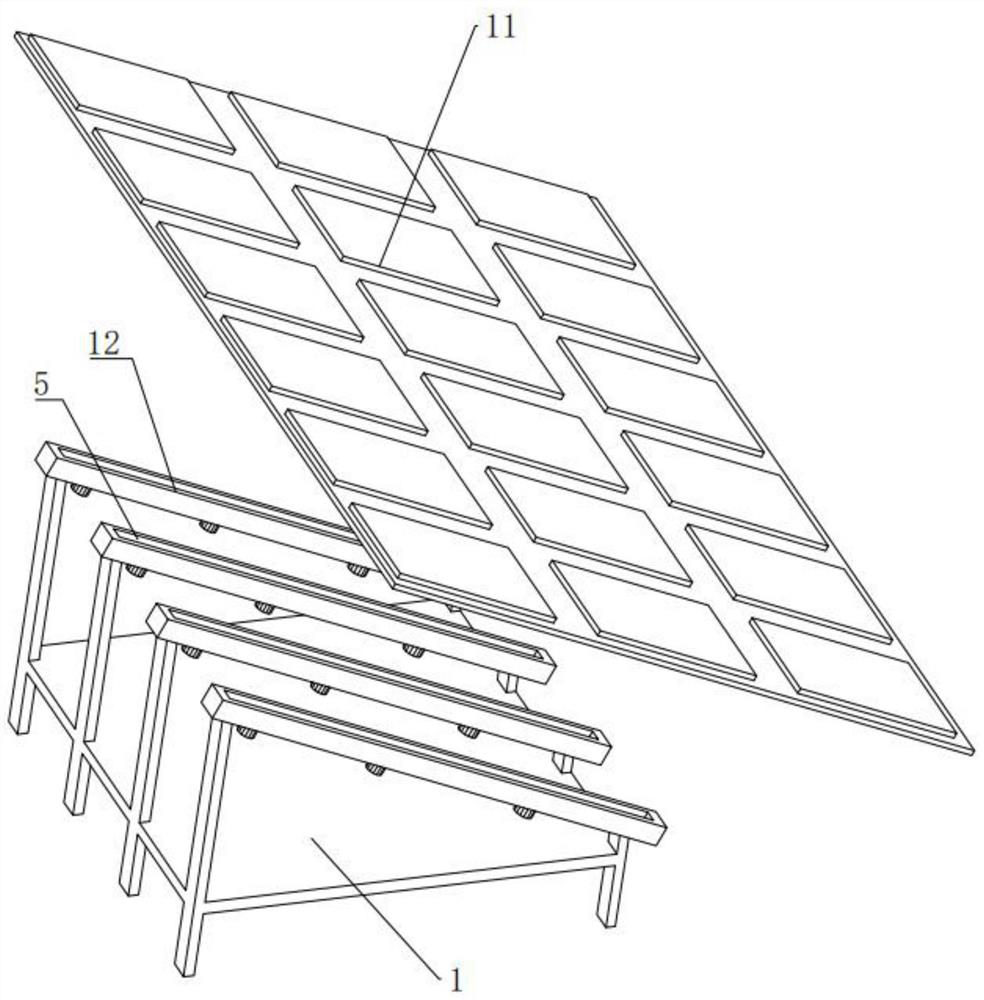

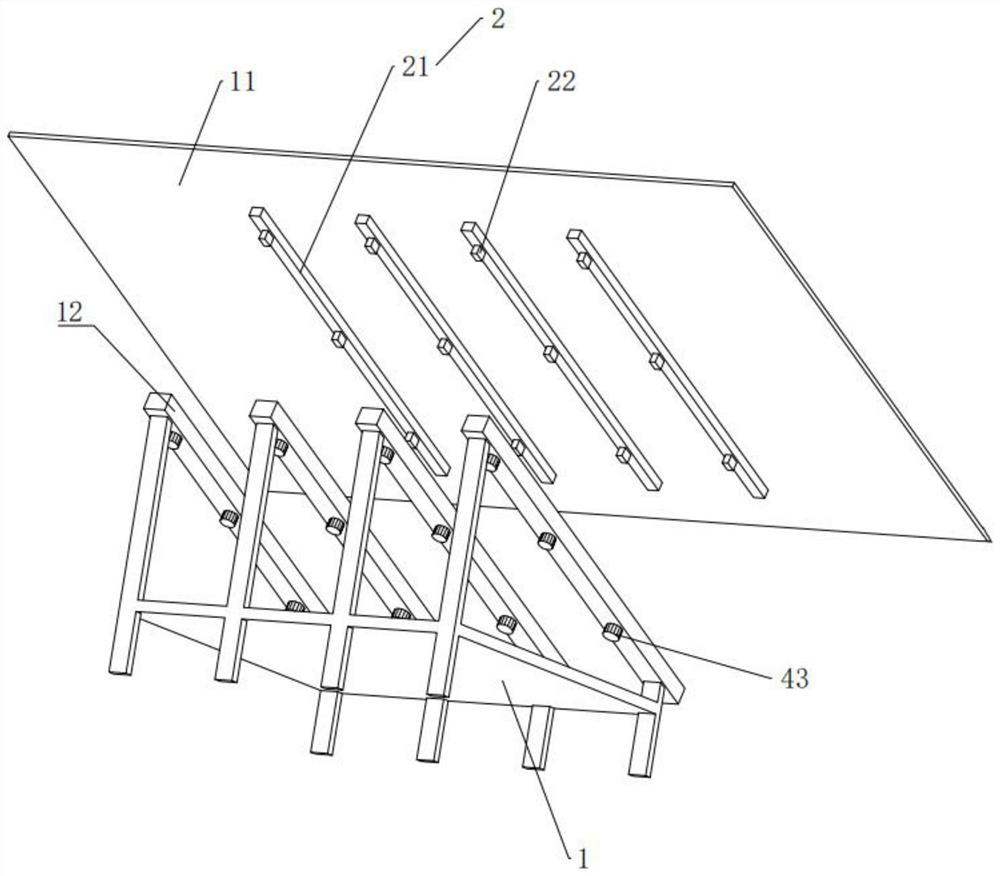

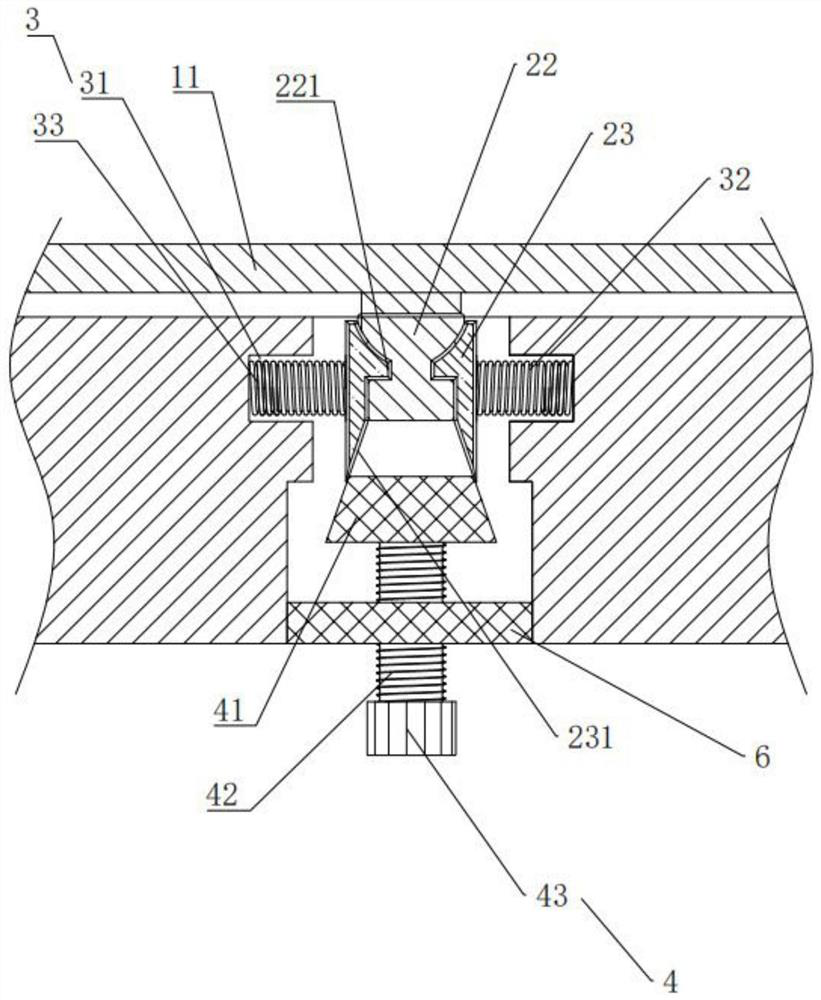

[0038] This embodiment is provided with a solar module mounting structure, such as Figure 1-3 As shown, including the base 1 and the solar photovoltaic plate 11, the solar photovoltaic plate 11 and the base 1 are connected between the mounting bracket 2, the mounting bracket 2 includes a connecting rod 12, a connecting strip 21, a connection cartridge 22, a movable block 23, a reset Driver 3 and the open piece 4. The inclination angle of the connecting rod 12 relative to the horizontal plane is 40 ° ± 10 °, and the latitude adjustment is adjusted according to the latitude of the mounting position.

[0039] like Figure 1-3 As shown, the connecting strut 12 is fixed to the base 1, which is inclined with respect to the horizontal plane for supporting the solar photovoltaic plate 11; the connecting strip 21 is fixed to the solar photovoltaic plate 11 toward one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com