Method for preparing hard carbon material from biomass waste physalis pubescens leaves, and sodium ion battery

A sodium-ion battery and waste mushroom technology, which is applied in non-aqueous electrolyte storage batteries, electrolyte storage battery manufacturing, secondary batteries, etc. The effect of saving resources and realizing commercialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of a hard carbon material derived from biomass waste mushroom leaves, comprising the following steps:

[0027] (1) The leaves of Guniang fruit were washed several times with deionized water and then dried in an air-blast drying oven at 80 °C for 12 h;

[0028] (2) Soak the material in step (1) in a 1 mol / L hydrochloric acid solution for 24 h;

[0029] (3) The material in step (2) is washed repeatedly with deionized water until neutral;

[0030] (4) Under an argon atmosphere, raise the material in step (3) to 1400 °C at a heating rate of 5 °C / min in a tube furnace, keep it warm for 2 hours, and then lower it to room temperature; take it out and grind it into powder, Obtain the sodium ion battery hard carbon negative electrode material, marked as HC-1400.

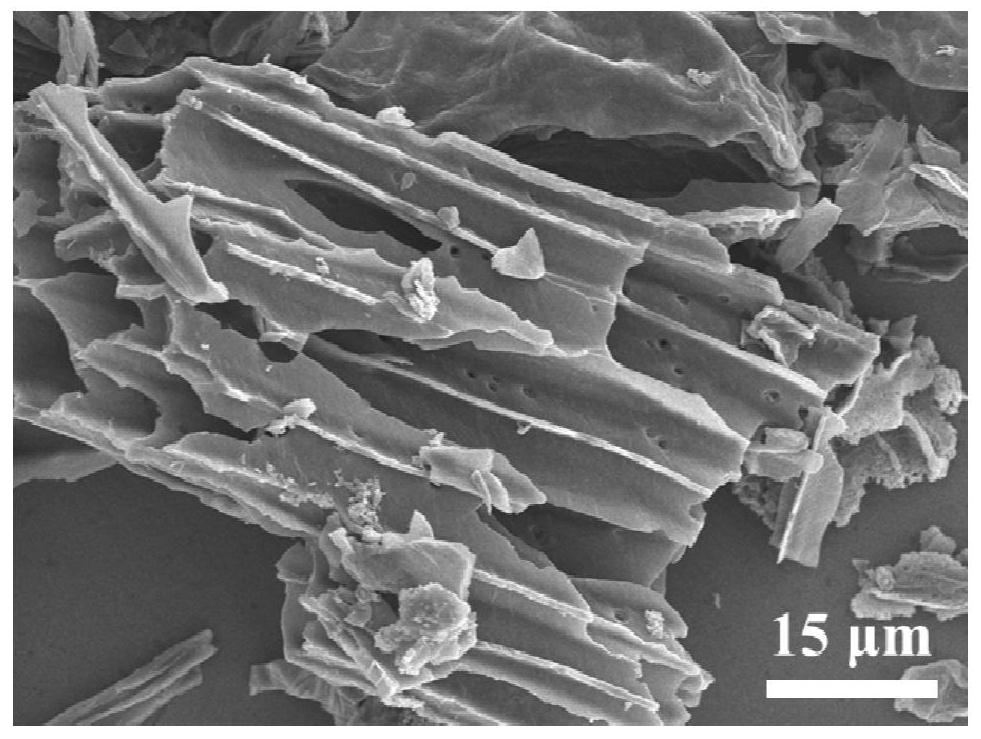

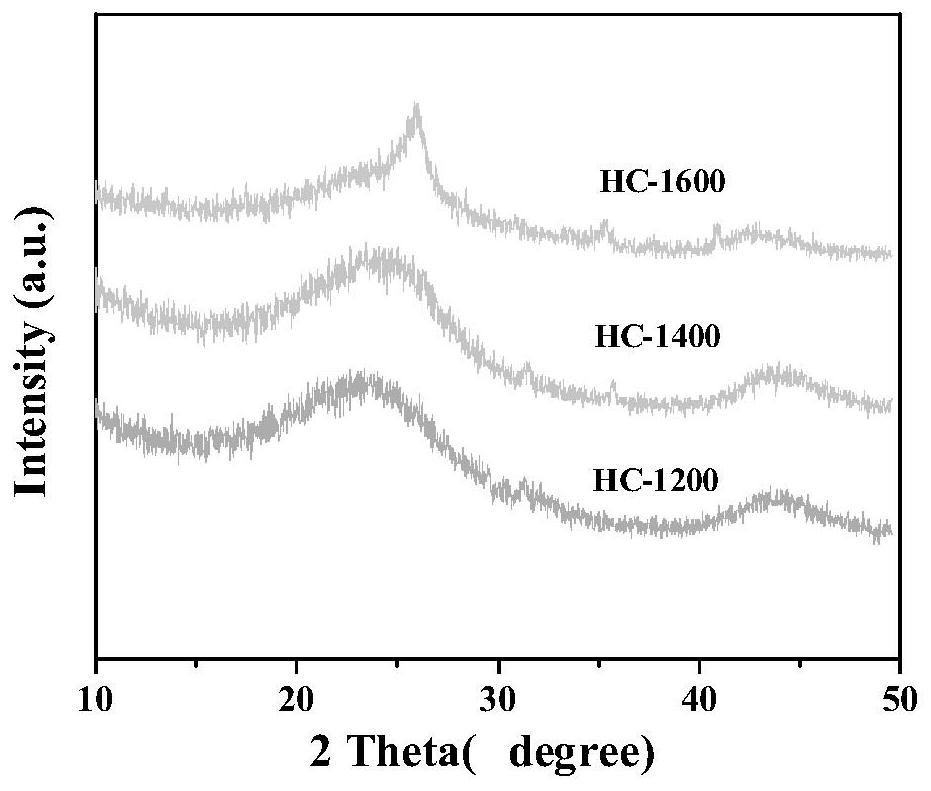

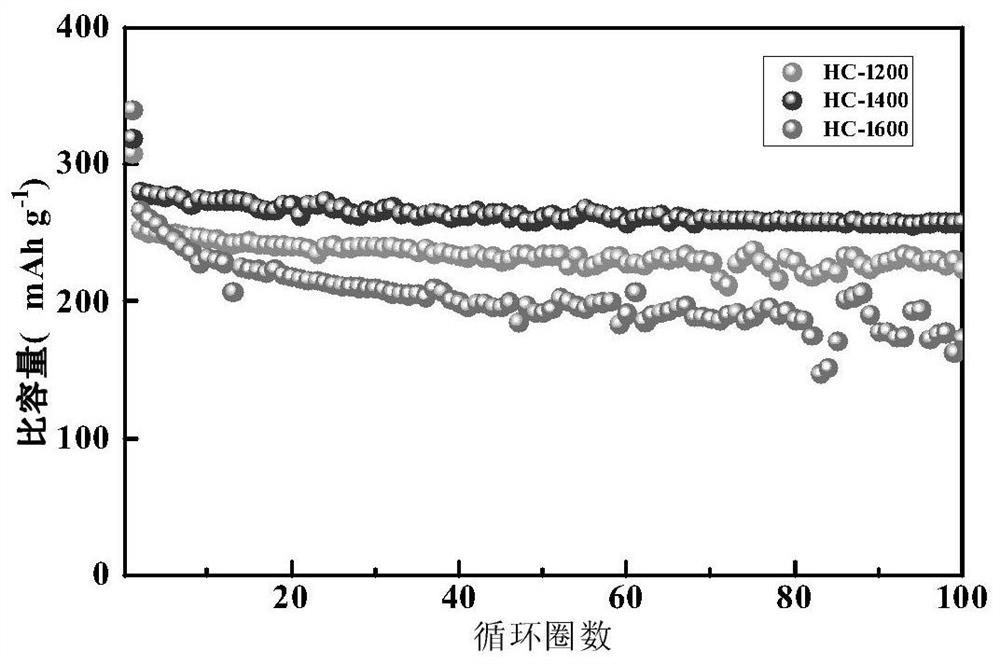

[0031] See attached figure 1 , is the SEM image of the biomass hard carbon material prepared in this example. It can be seen that the material shows the morphology of porous channels, which is c...

Embodiment 2

[0034] A preparation method of a hard carbon material derived from biomass waste mushroom leaves, comprising the following steps:

[0035] (1) The leaves of Guniang fruit were washed several times with deionized water and then dried in an air-blast drying oven at 80 °C for 12 h;

[0036] (2) Soak the material in step (1) in a 1 mol / L hydrochloric acid solution for 24 h;

[0037] (3) The material in step (2) is washed repeatedly with deionized water until neutral;

[0038] (4) Under an argon atmosphere, raise the material in step (3) to 1200 °C in a tube furnace at a rate of 5 °C / min, keep it warm for 2 h, and then lower it to room temperature; take it out and grind it into powder , to obtain a hard carbon negative electrode material for sodium ion batteries, marked as HC-1200.

Embodiment 3

[0040] A preparation method of a hard carbon material derived from biomass waste mushroom leaves, comprising the following steps:

[0041] (1) The leaves of Guniang fruit were washed several times with deionized water and then dried in an air-blast drying oven at 80 °C for 12 h;

[0042] (2) Soak the material in step (1) in a 1 mol / L hydrochloric acid solution for 24 h;

[0043] (3) The material in step (2) was washed with deionized water several times until neutral, and then dried in a blast drying oven at 80 °C for 12 h;

[0044] (4) Under an argon atmosphere, raise the material in step (3) to 1600 °C in a tube furnace at a rate of 5 °C / min, keep it warm for 2 h, and then lower it to room temperature; take it out and grind it into powder , to obtain a hard carbon negative electrode material for sodium ion batteries, marked as HC-1600.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com