Fermentation method of herbal trichosporon kashiwayama with spot fading effect

A yeast fermentation and film coating technology, applied in the biological field, achieves the effects of good anti-inflammatory activity, low cost and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

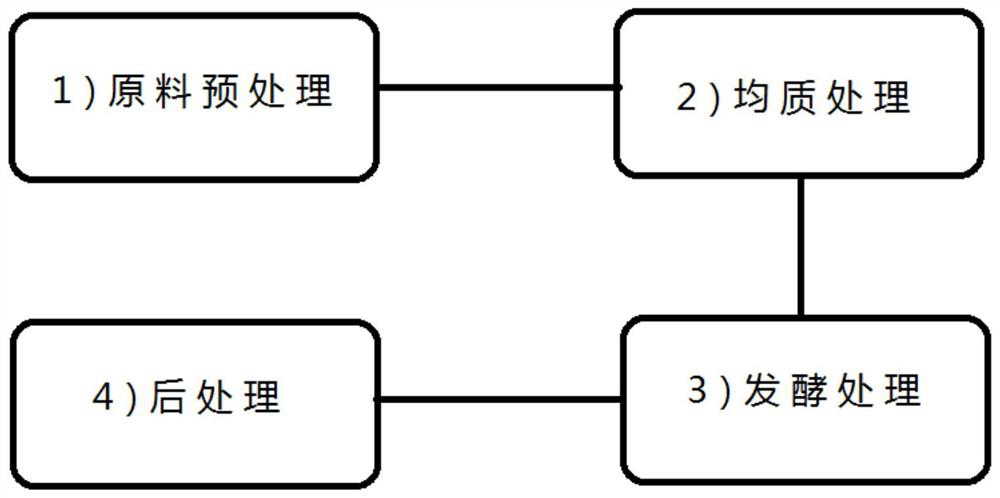

Method used

Image

Examples

Embodiment 1

[0064] Present embodiment 1 specifically comprises the following steps:

[0065] (1) Raw material pretreatment: select 200 grams of dry raw material mixture with a water content of less than 10%, and grind it to 200-300 mesh.

[0066] (2) Homogenization treatment: use a micro-jet high-pressure homogenizer to suck the feed through a booster pump or a plunger pump of the homogenizer; the ratio of raw material mixture to water is 1:8 times pure water, and the pH is adjusted to 7.2; Material pressurization: The material is pressurized to a set pressure value of 35Mpa in the plunger booster pump; the pressurized material reaches an ultra-fine homogeneous state in the micro-jet high-pressure homogenizer, and the homogenized raw material The mixture is homogeneous material and is collected into the discharge container. During this process, the material treated by high-pressure micro-jet is cooled by a heat exchanger. In this embodiment, the real-time temperature control temperature ...

Embodiment 2

[0072] Present embodiment 2 specifically comprises the following steps:

[0073] (1) Raw material pretreatment: select 200 grams of dry raw material mixture with a water content of less than 10%, and grind it to 200-300 mesh.

[0074] (2) Homogenization treatment: use a micro-jet high-pressure homogenizer to suck the feed through a booster pump or a homogenizer plunger pump; the ratio of raw material mixture to water is 1:10 times pure water, and the pH is adjusted to 7.2; Material pressurization: The material is pressurized to the set pressure value of 38Mpa in the plunger booster pump; the pressurized material reaches an ultra-fine homogeneous state in the micro-jet high-pressure homogenizer, and the homogenized raw material The mixture is homogeneous material and is collected into the discharge container. During this process, the material treated by high-pressure micro-jet is cooled by a heat exchanger. In the embodiment, the real-time temperature control temperature is se...

Embodiment 3

[0080] Present embodiment 3 specifically comprises the following steps:

[0081] (1) Raw material pretreatment: select 200 grams of dry raw material mixture with a water content of less than 10%, and grind it to 200-300 mesh.

[0082] (2) Homogenization treatment: use a micro-jet high-pressure homogenizer to suck the feed through a booster pump or a homogenizer plunger pump; the ratio of raw material mixture to water is 1:8 times pure water, and the pH is adjusted to 7.5; Material pressurization: The material is pressurized to a set pressure value of 35.8Mpa in the plunger booster pump; the pressurized material reaches an ultra-fine homogeneous state in the micro-jet high-pressure homogenizer, and the homogenized Raw material mixture homogeneous material, is collected into the discharge container. During this process, the material treated by high-pressure micro-jet flow is cooled by a heat exchanger. In this embodiment, the real-time temperature control temperature is set to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com