Doping device and method for czochralski silicon single crystal

A technology of Czochralski silicon and single crystal, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of high pollution in the furnace, low doping rate of arsenic and phosphorus, high resistivity of silicon single crystal, etc. , to avoid bubbling, increase doping rate, and reduce volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Pulling N-type 6-inch arsenic-doped single crystal, the polysilicon feed rate is 60kg, and the crystal orientation is .

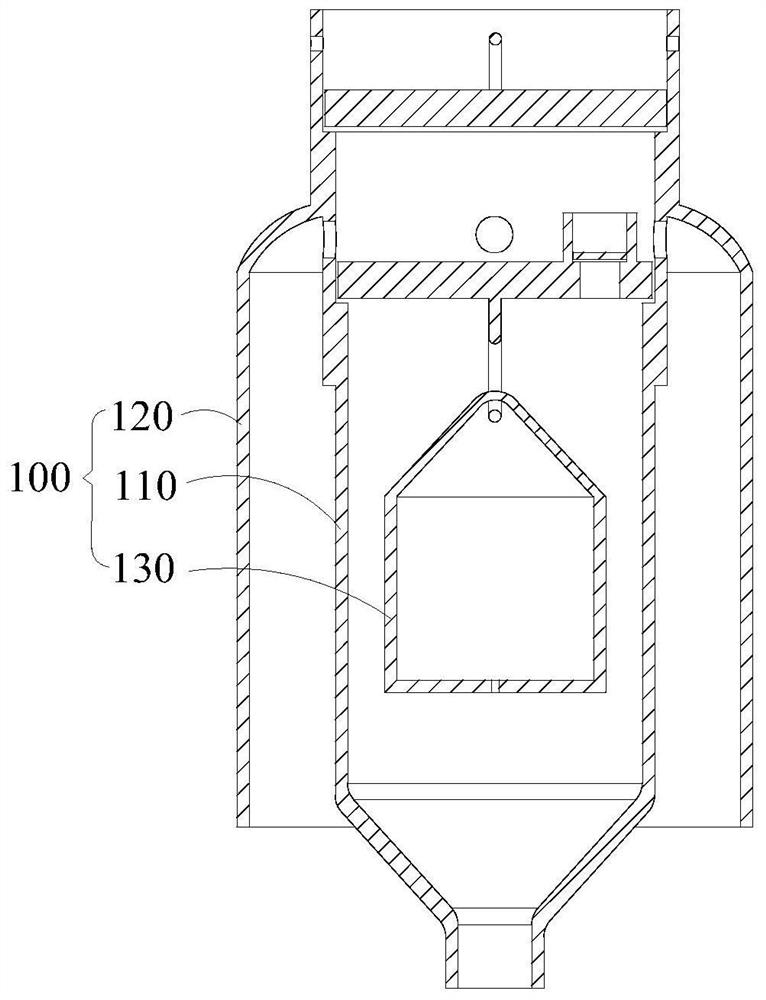

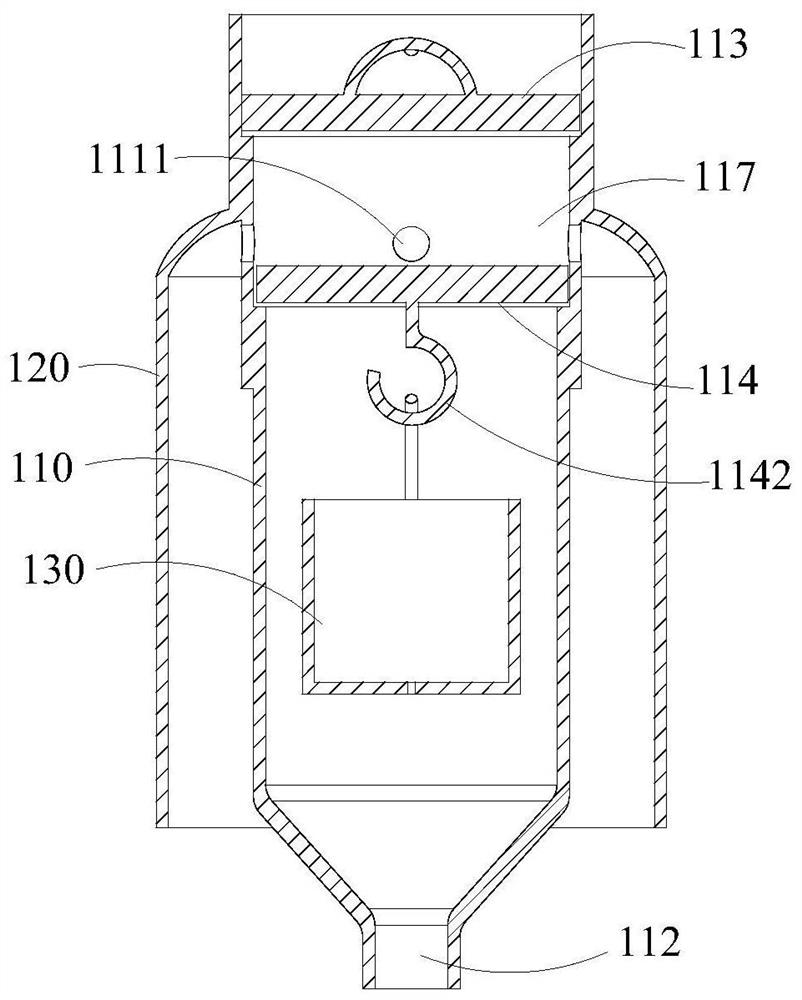

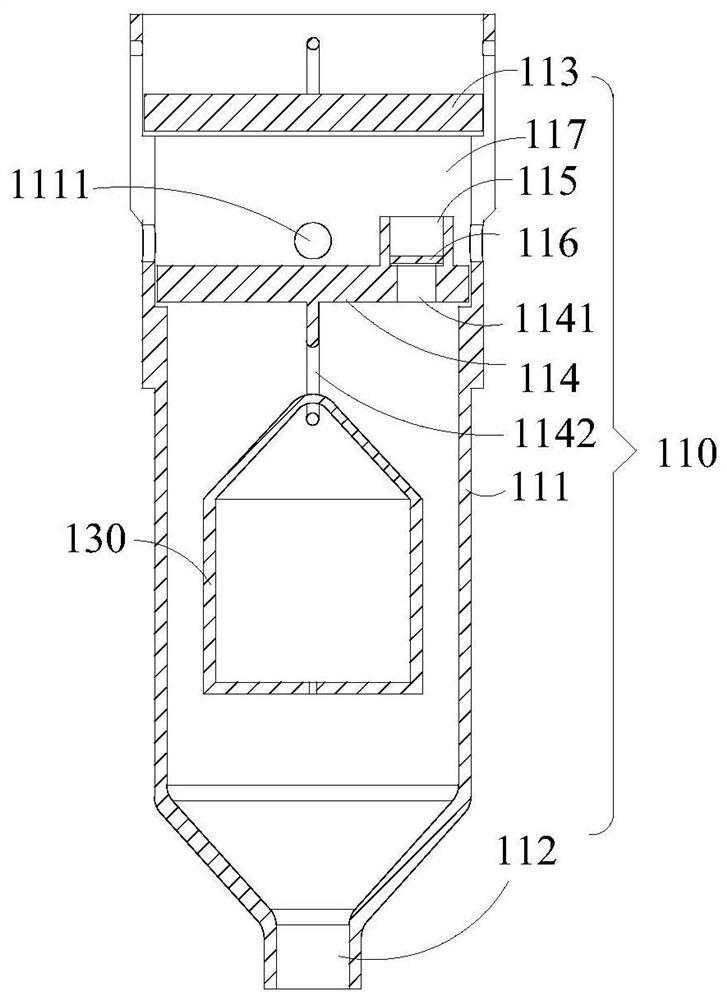

[0053] Put 60kg of silicon raw material in the quartz crucible 210 for compounding. After the compounding is completed, set the temperature in the single crystal furnace 200 to 1280°C, and the argon flow in the single crystal furnace 200 is constant at 75L / min, keeping the temperature in the single crystal furnace 200 Furnace pressure is 20Kpa, stable under this parameter for half an hour, put 410g of arsenic in the quartz cup 130, hang the quartz cup 130 on the hook 1142 of the second quartz cover 114, cover the second quartz cover 114, row Gas piece 116, the first quartz cover 113, the whole doping part 100 is lowered vertically to the lower end of the immersion tube 112 and enters 20mm below the silicon melt liquid level for doping, and observes the volatilization of arsenic in the quartz cup 130. After the arsenic volatilizes completely, the dopi...

Embodiment 2

[0059] Pulling N-type 6-inch arsenic-doped single crystal, the polysilicon feed rate is 60kg, and the crystal orientation is .

[0060] Put 60kg of silicon raw material in the quartz crucible 210 for compounding. After the compounding is completed, set the temperature in the single crystal furnace 200 to 1320°C, and the flow rate of argon in the single crystal furnace 200 is constant at 85L / min, keeping the temperature in the single crystal furnace 200 Furnace pressure is 30Kpa, stable under this parameter for half an hour, put 410g of arsenic in the quartz cup 130, hang the quartz cup 130 on the hook 1142 of the second quartz cover 114, cover the second quartz cover 114 successively, row Gas piece 116, the first quartz cover 113, the whole doping part 100 is lowered in the vertical direction to the lower end of the immersion tube 112 and enters 30mm below the silicon melt liquid level for doping, and observes the volatilization of arsenic in the quartz cup 130. After the arse...

Embodiment 3

[0066] Pulling N-type 6-inch phosphorous-doped single crystal, the feeding amount is 60kg, and the pulling crystal orientation is .

[0067] Put 60kg of silicon raw material in the quartz crucible 210 for compounding. After the compounding is completed, set the temperature in the single crystal furnace 200 to 1280°C, and the argon flow in the single crystal furnace 200 is constant at 75L / min, keeping the temperature in the single crystal furnace 200 Furnace pressure is 20Kpa, stable under this parameter for half an hour, put 200g of phosphorus in the quartz cup 130, hang the quartz cup 130 on the hook of the second quartz cover 114, cover the second quartz cover 114 successively, exhaust Plate 116, the first quartz cover 113, the whole doping part 100 is lowered to the lower end of the immersion tube 112 in the vertical direction and enters 20 mm below the silicon melt liquid level for doping, and observes the volatilization of phosphorus in the quartz cup 130. After the volat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com