Deep vertical fast-assembly graphite grounding electrode and processing technology thereof

A graphite grounding and processing technology, applied in the direction of connection, connection contact material, electrical components, etc., can solve the problems of small flow capacity of graphite material, limited excavation of hard objects, resistance reduction and construction difficulties, etc. Beneficial for dispersing flow, slowing down electrochemical corrosion, maintaining compactness and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

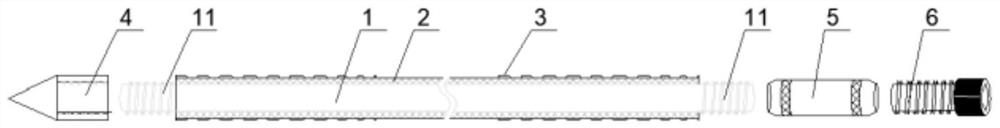

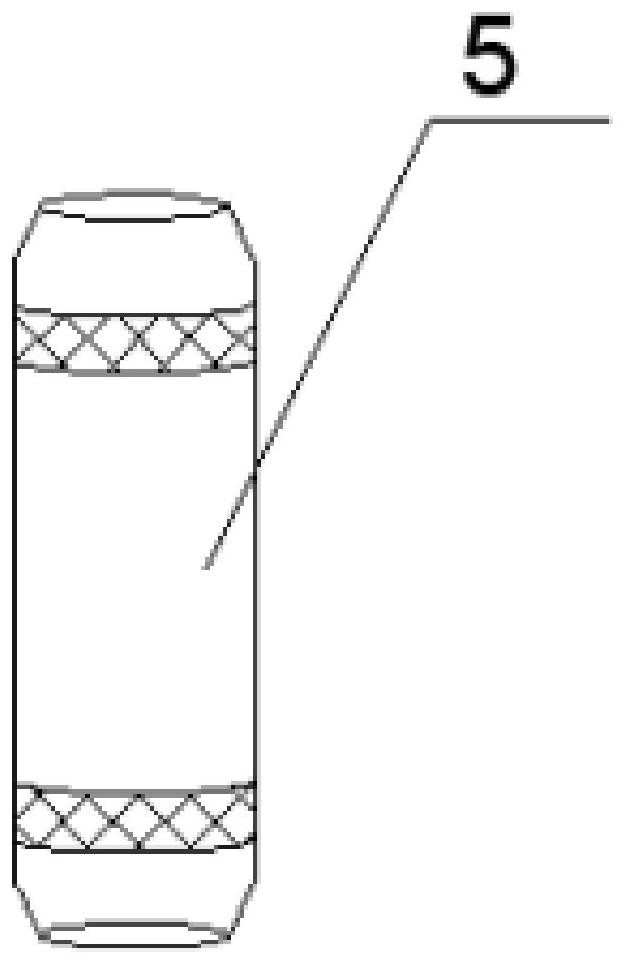

[0036] Such as Figure 1-4As shown, the present embodiment provides a deep vertical fast-installed graphite grounding electrode, which includes several sections of copper rods 1 and graphite braided layers 2 tightly covering the outside of the red copper rods 1, and the periphery of the red copper rods 1 and the graphite braided layer 2 passes through several The stainless steel casing 3 is fastened, and both ends of the copper rod 1 are provided with external threads 11, the external threads 11 at one end of the copper rod 1 are threaded to be connected with the cone head 4, and the external threads 11 at the other end are threaded through the connector 5 to have a tail end seal Bolt 6;

[0037] Among them, the red copper rod 1 is obtained by electroplating or cold-rolling a layer of red copper on the outer layer of the high-strength carbon steel substrate, which improves the corrosion resistance of the high-strength carbon steel substrate; 32mm; the inner cavity of the cone...

Embodiment 2

[0044] Such as figure 1 , Figure 5 As shown, this embodiment provides an integrated conveying, cutting, and crimping device for the conveying, cutting, and crimping procedures of the deep vertical fast-loading graphite grounding electrode, specifically when the deep vertical fast-packing graphite grounding electrode meets When there are hard objects such as rocks and large stones in the deep underground, and the vertical installation cannot be continued, cut it off at a length 200mm above the ground, and use a stainless steel sleeve 3 with a length of 100-120mm to weave a 50mm long copper rod 1 and graphite Layer 2 is crimped, and the remaining 50-60mm stainless steel sleeve 3 is not crimped, and the uncrimped stainless steel sleeve 3 is partially crimped with the above-mentioned truncated copper rod 1 and graphite braided layer 2, so that the graphite grounding electrode completes the deep vertical fast It improves the overall processing and installation efficiency.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com