Low-speed direct-drive motor disturbance suppression method based on sliding mode and disturbance compensation

A technology of disturbance compensation and disturbance suppression, applied in motor generator control, motor control, AC motor control, etc., can solve the problem that the low frequency time-varying torque disturbance suppression effect is not obvious, so as to improve the disturbance suppression ability and reduce the complexity. , the effect of the simple structure of the observer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

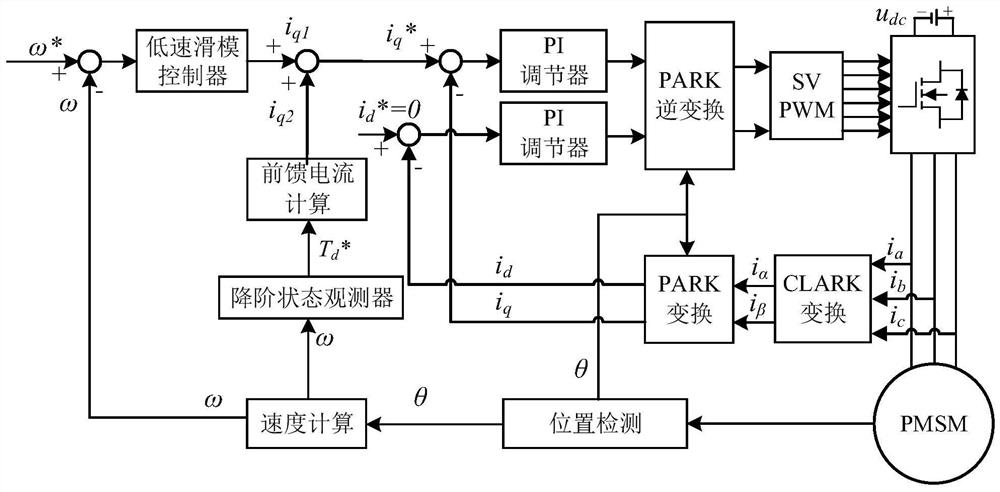

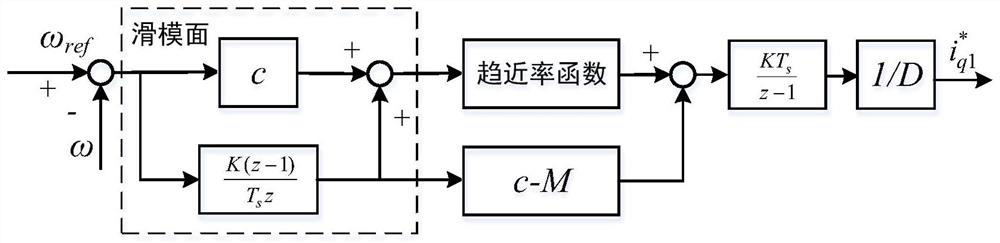

[0071] Further detailed description of the technical solutions of the present invention will be described below with reference to the drawings:

[0072] (1) collecting a three-phase current information, coordinate transformation, to establish vector control mathematical model of the permanent magnet synchronous motor (PMSM) dq coordinate system;

[0073]

[0074] Where, ω is the mechanical angular velocity, p n Number of pole pairs, u d U q Is d and q-axis armature voltage component, i d I q Corresponds to the armature current component, R s The armature resistance, ψ f The motor rotor flux, L d L q Motor direct and quadrature axis inductance.

[0075] In particular, for a surface mounted permanent magnet synchronous motor L d = L q , Its torque equation is:

[0076]

[0077] Mechanical equations of motion are:

[0078]

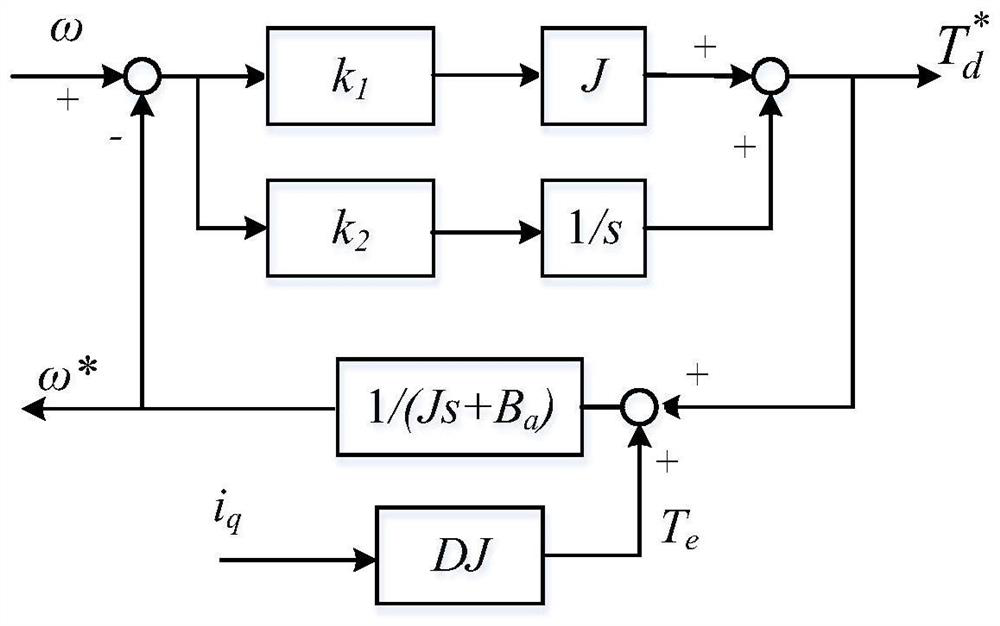

[0079] Among them, T e A permanent magnet synchronous motor electromagnetic torque, J is the moment of inertia, T L Is the load torque, B a For the damping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com