Ultra-low emission system for high-sulfur sludge incineration flue gas

A technology of sludge incineration and discharge system, which is applied in the direction of gas treatment, combined device, membrane technology, etc., can solve the problem that the disposal cannot meet the requirements, and achieve the effects of saving operating costs, reducing waste water discharge, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

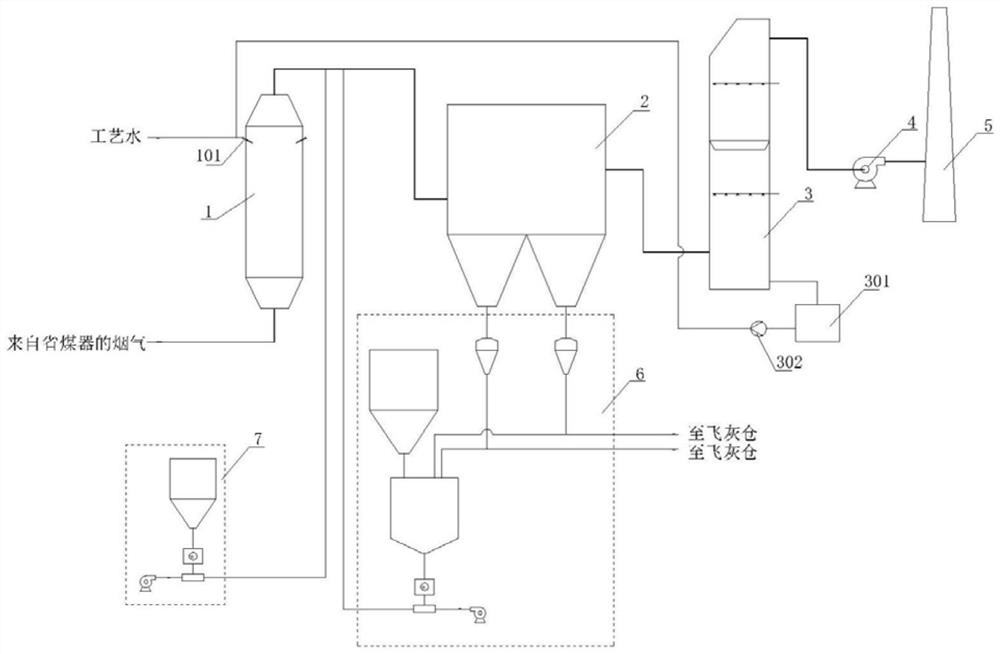

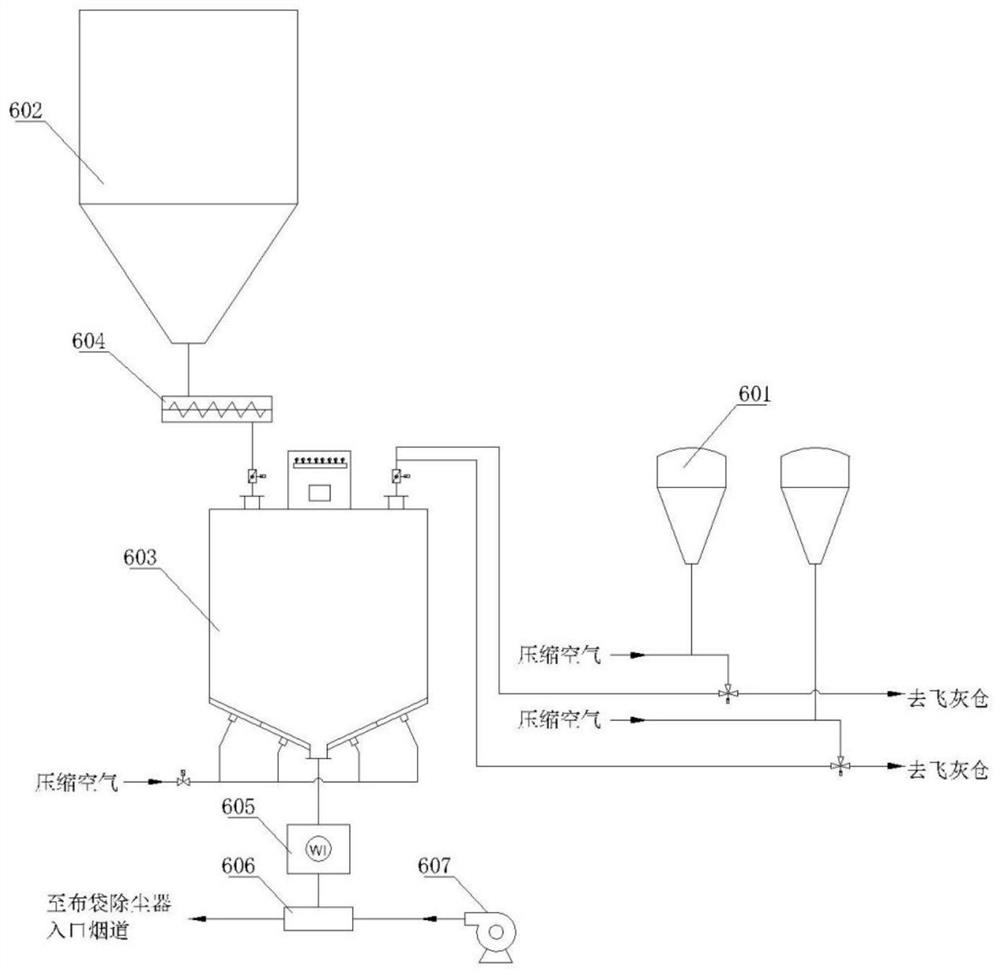

[0023] refer to Figure 1 to Figure 2 An ultra-low emission system for high-sulfur sludge incineration flue gas in the present invention, comprising a circulating semi-dry desulfurization system, a bag dust removal system, a wet scrubbing system, an induced draft fan 4, and a chimney 5 arranged sequentially along the flue gas treatment direction, and also includes Activated carbon injection device 7, the circulating semi-dry desulfurization system includes cooling humidification tower 1, desulfurization agent mixing and injection device 6, the flue gas outlet of the cooling humidification tower 1 is connected to the dust collector of the bag dust removal system through the mixing flue 2 (bag dust collector), the ash discharge outlet of the dust collector 2 is connected to the desulfurization agent mixing and injection device 6, and the outlets of the desulfurization agent mixing and injection device 6 and the activated carbon injection device 7 are respectively connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com