Supported solid acid catalyst and preparation method thereof

A solid acid catalyst, supported technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor reactivity and selectivity, high requirements for production and processing equipment, clean cleaning, etc. Achieve the effects of high reactivity and selectivity, low processing equipment requirements, and easy production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

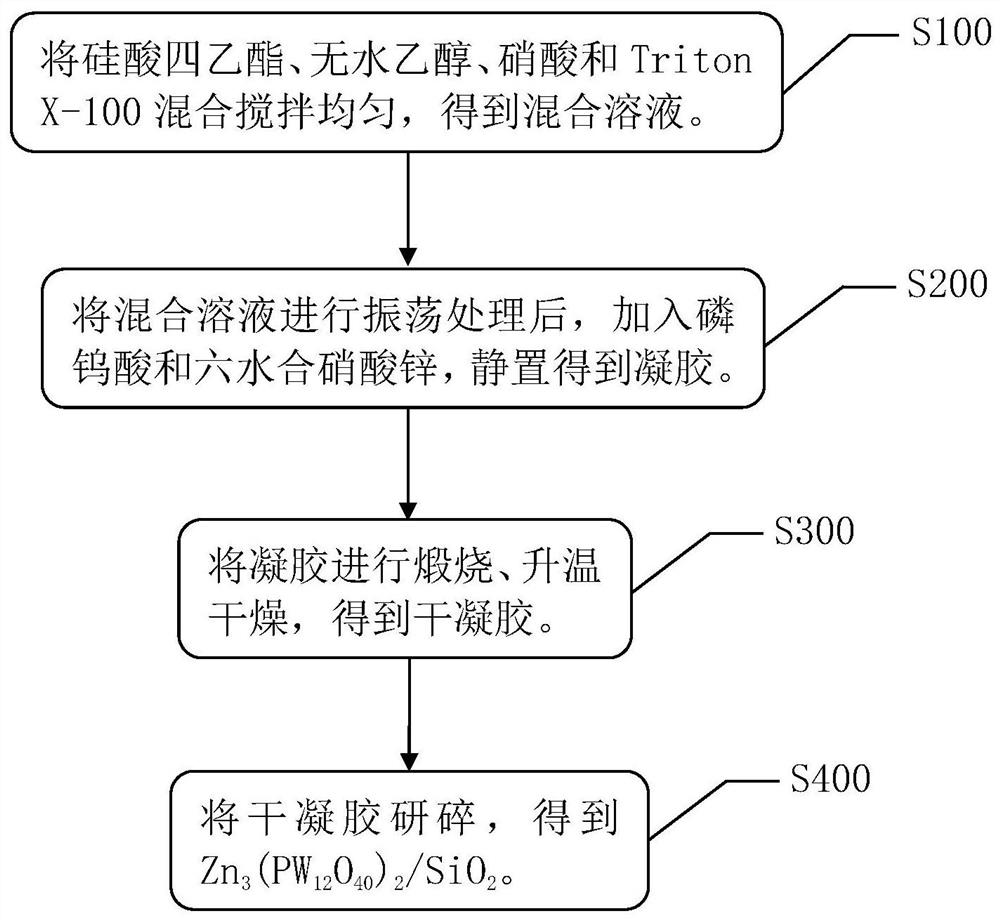

[0022] like figure 1 Shown, the present invention also provides a kind of preparation method of supported solid acid catalyst, comprises the following steps:

[0023] Step 100. Mix and stir tetraethyl silicate, absolute ethanol, nitric acid and Triton X-100 evenly to obtain a mixed solution; specifically: first add tetraethyl silicate, absolute ethanol and nitric acid to the container in sequence, and then Add Triton X-100, mix and stir well.

[0024] Step 200. Shaking the mixed solution (specifically: putting the mixed solution into an ultrasonic oscillator for 5 minutes), adding phosphotungstic acid and zinc nitrate hexahydrate, and standing still to obtain a gel.

[0025] Step 300. The gel is calcined, heated and dried to obtain a dry gel; specifically, the gel is placed in a drying oven and calcined in an air atmosphere, and then the gel is placed in a muffle furnace, and Calcination under nitrogen atmosphere to obtain xerogel; wherein, the calcination temperature of "ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com