Medium-high speed ship diesel engine cylinder cover machining device

A marine diesel engine and processing device technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of intricate piping system, high cost, inconvenient use, etc., and achieve simple and fast operation, fast and convenient operation, and guaranteed Effect of connection strength and tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

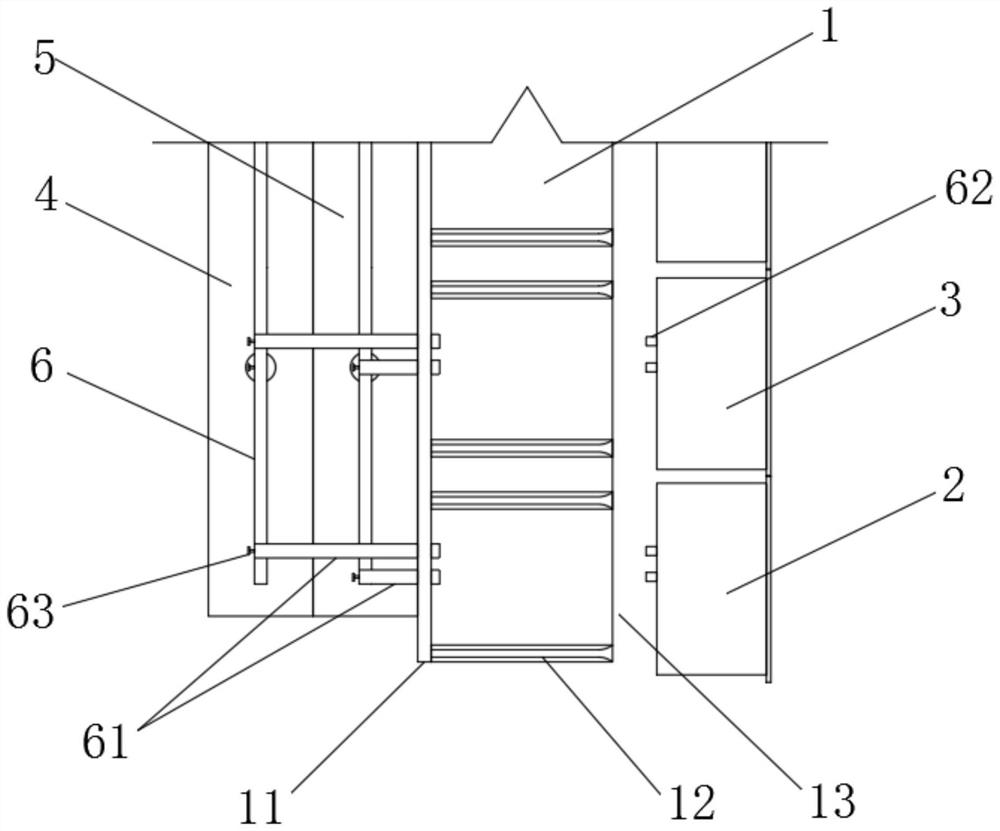

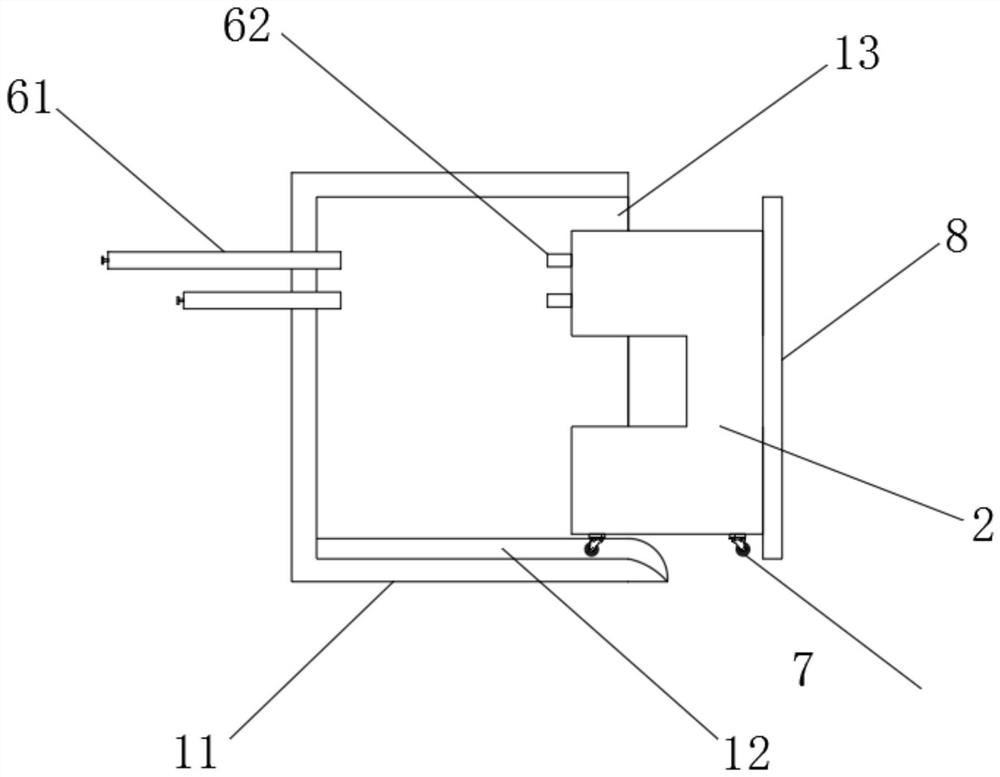

[0030] Such as Figure 1-5 As shown, a medium and high-speed marine diesel engine cylinder head processing device includes an assembly platform 1, a rough machining machine tool 2, a finishing machine tool 3, a No. 1 cutting fluid treatment system 4, a No. 2 cutting fluid treatment system 5, and a pipeline connection system 6;

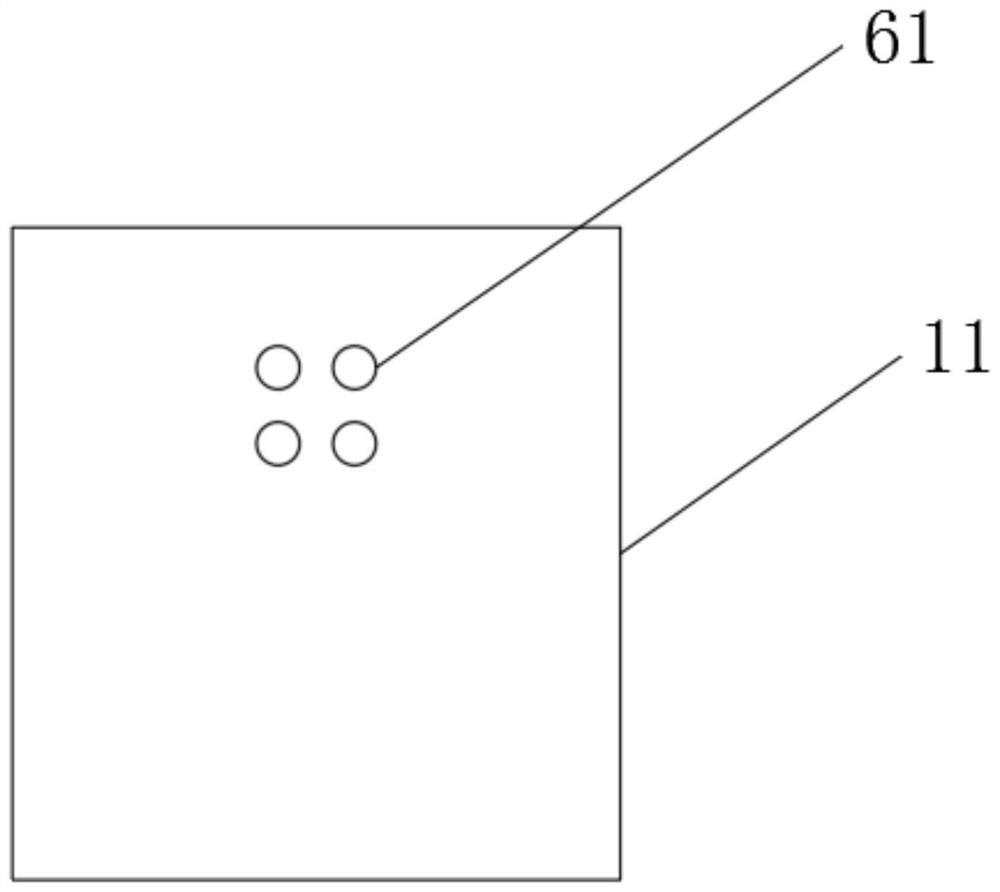

[0031] The assembly platform 1 includes an assembly box 11 whose side wall is set as an opening 13, and a plurality of sets of guide rails 12 arranged at the bottom of the inner cavity of the assembly box 11. The roller 7 at the bottom of the lathe 3 cooperates. The roughing machine tool 2 / finishing machine tool 3 is fixedly provided with a baffle plate 8 on the side wall of the opening 13, and the top and bottom ends of the baffle plate 8 are in contact with the top and bottom ends of the opening 13, and two adjacent baffle plates 8 fit between.

[0032] The rough machining machine tool 2 and the finish machining machine tool 3 are clamped on the as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com