Preparation method of low-alloy hammerhead for rotary radial precision cold forging machine tool

A rotating radial, low-alloy technology, used in metal processing equipment, metal material coating technology, vacuum evaporation plating and other directions, can solve problems such as micro-efficiency, and achieve improved matrix toughness, enhanced hardness, and refined grains. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

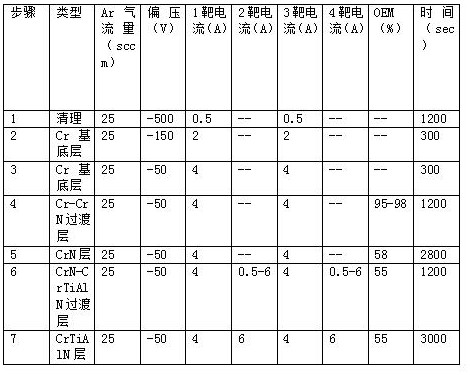

Image

Examples

Embodiment Construction

[0027] This specific embodiment adopts following technical scheme: its operating steps are as follows:

[0028] Step 1, substrate selection:

[0029] Choose 7Cr 2 NiMoSiVRE cold work die steel is used as the base material, and its chemical composition weight percentage is as follows: C0.68-0.78%, Si 0.64-0.74%, Mn 0.75-0.85%, Cr 2.3-2.45%, Ni 0.32-0.42%, Mo 0.20- 0.35%, V 0.20-0.30%, RE 0.05-0.08%, the rest is supplemented by Fe;

[0030] Step 2, matrix forging:

[0031] Use forging equipment to forge the above-mentioned base material, that is, first quickly forge and upset, so that the forging ratio of the material is increased from 3-4 to 7.0-8.5, and then use radial forging to form a steel ingot. The initial forging temperature is 1100-1150 °C, the final forging temperature is 850-950 °C, and the forging ratio is 7.0-8.5;

[0032] Step 3, substrate production:

[0033] Heating the steel ingot, and then use 20 / 30MN fast forging machine to open the billet to form a forgi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com