Method for preparing copper-based amorphous composite coating through laser cladding

A technology of laser cladding and composite coating, which is applied in the coating, metal material coating process, etc., can solve the problems of excessive dilution of the substrate, poor bonding force between the coating and the substrate, and poor coating performance, so as to increase the absorption rate , Improve metallurgical bonding, improve the effect of low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

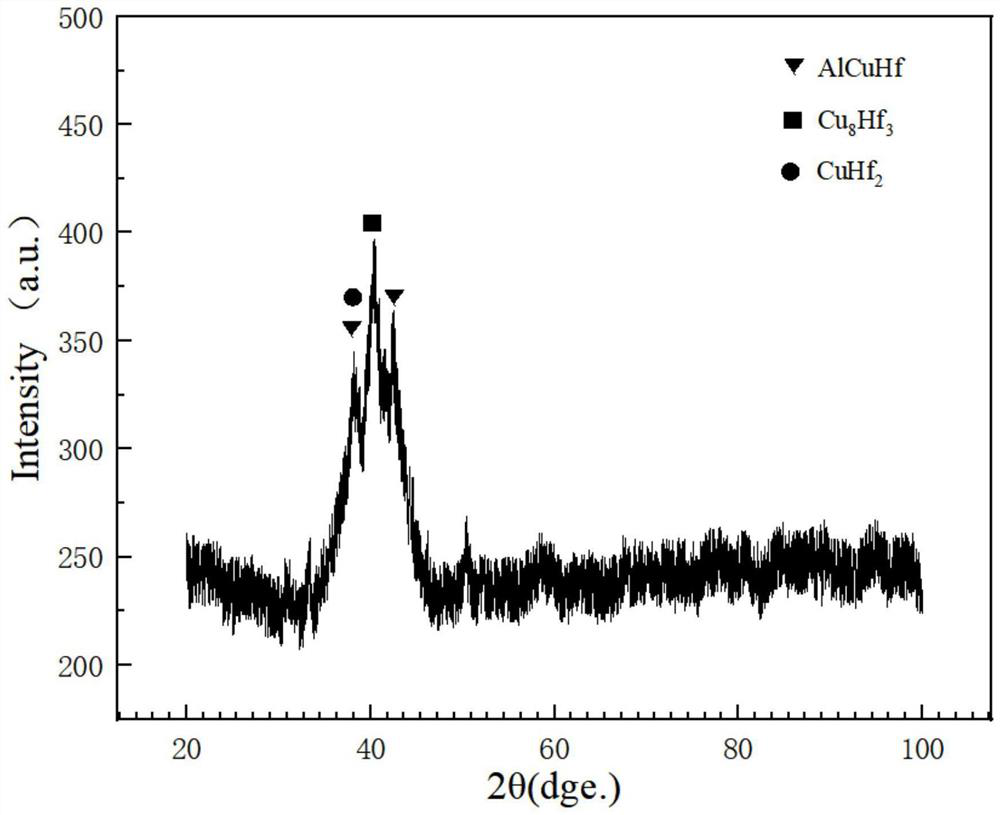

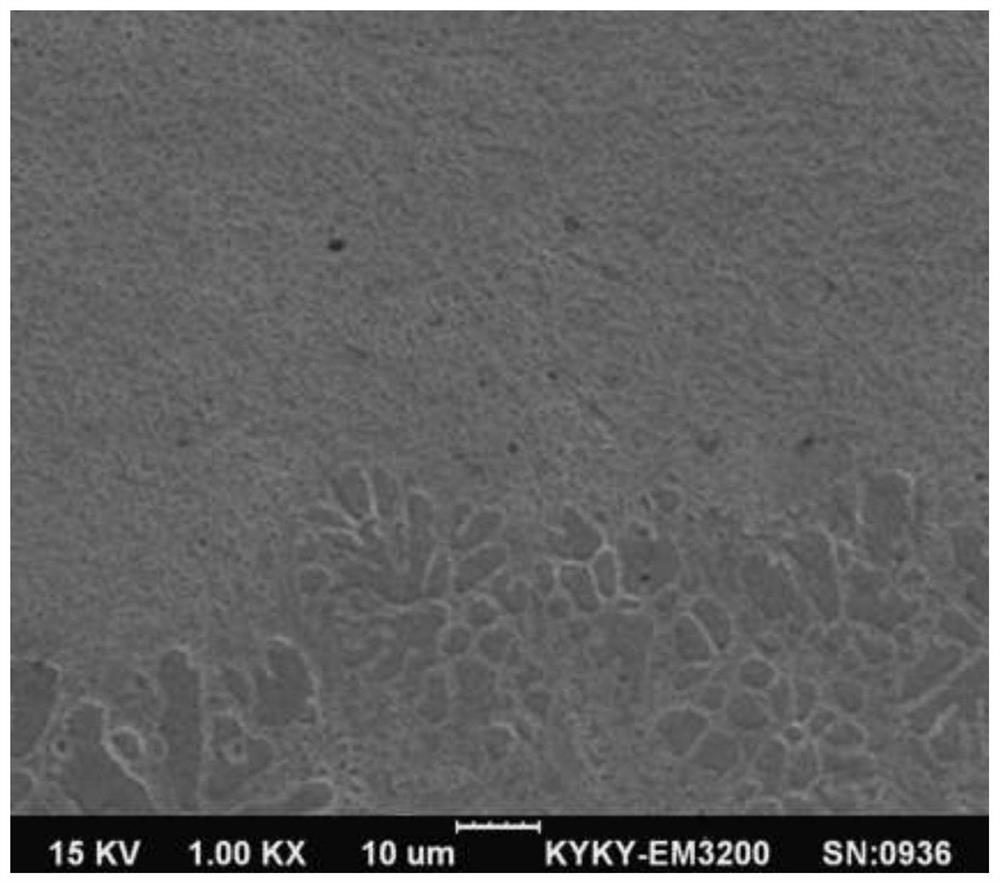

[0031] A method for preparing a copper-based amorphous composite coating by laser cladding, the atomic percentage of each component of the smelted alloy is Cu 50-x Hf 44-2y Al 6+y Mo x Ta y , where x is 3 and y is 2.

[0032] (1) Preparation of smelted alloy powder

[0033] The atomic percentage of each component of the smelted alloy is: Cu 47 Hf 40 Al 8 Mo 3 Ta 2 .

[0034] Use 360-mesh sandpaper to polish the Cu sheet, Hf block, Al block, Mo wire and Ta block raw materials with a purity of 99.0%, convert the atomic percentage of each component of the smelted alloy into the corresponding mass percentage, and then weigh the corresponding mass percentage according to the mass percentage. Metal Cu, Hf, Al, Mo and Ta, and place each raw material in a vacuum arc melting furnace, increase the melting current to 150A, and repeat the melting three times, each time for 10 to 15 seconds, to ensure that the formed alloy composition is uniform; After the obtained alloy is crus...

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 is: x=3, y=1, and the atomic percentage of each component of the smelted alloy is Cu 47 Hf 42 Al 7 Mo 3 Ta 1 ; Set the laser power to 2200W and the scanning speed to 10mm / s.

[0043] Others are the same as in Example 1, and a copper-based amorphous composite coating can be obtained.

Embodiment 3

[0045] The difference between this embodiment and embodiment 1 is: x=2, y=2, and the atomic percentage of each component of the smelted alloy is Cu 48 Hf 40 Al 8 Mo 2 Ta 2 ; Set the laser power to 2400W and the scanning speed to 12mm / s.

[0046]Others are the same as in Example 1, and a copper-based amorphous composite coating can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com