Spinning process for preparing regenerated polyester long fibers from waste fiber products

A technology for regenerating polyester and waste fibers, applied in the direction of cellulose/protein conjugated rayon filament, conjugated synthetic polymer rayon filament, fiber chemical characteristics, etc., can solve problems such as lack of technology, achieve efficient removal, good Hygroscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

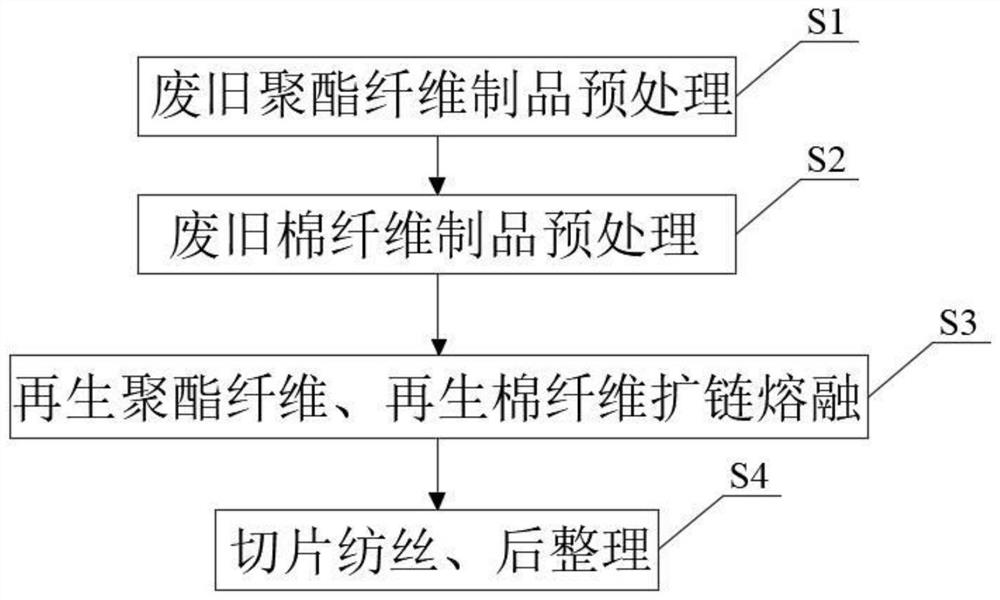

[0035] like figure 1 As shown, this embodiment provides a spinning process for preparing recycled polyester long fibers from waste fiber products, including the following steps:

[0036] S1. Pretreatment of waste polyester fiber products: Select waste polyester fiber products, and obtain recycled polyester fiber coarse material through pulverization, pickling, primary filtration, ultrasonic cleaning, secondary filtration, and drying, and the recycled polyester fiber coarse material is melted. Regenerated polyester fiber raw materials are obtained by extrusion; waste polyester fiber products are selected from waste polyester fabrics and waste polyester bottles, and the intrinsic viscosity of waste polyester fabrics is 0.55-0.65dl / g, impurity content ≥ 220mg / kg, moisture content ≥2%; the intrinsic viscosity of the waste polyester bottle is 0.72~0.82dl / g, the impurity content is ≥80mg / kg, and the moisture content is ≥1.5%.

[0037] S2. Pretreatment of waste cotton fiber products...

Embodiment 2

[0041] like figure 1 As shown, the spinning process for preparing regenerated polyester long fibers from waste fiber products provided in this example is different from Example 1 in that the chain extender in step S3 is selected from ethylene glycol; the raw materials of regenerated polyester fibers and regenerated cotton fibers The mass ratio of raw material, chain extender, cetyl phosphate salt, and polyethylene glycol is 1.9:0.6:0.8:0.03:0.25; the multiple of wet-heat drafting is 2.5; the washing and drying use clean water, and the washing temperature is 44 °C, and the drying temperature is 122 °C.

Embodiment 3

[0043] like figure 1 As shown, the spinning process for preparing regenerated polyester long fiber from waste fiber products provided in this example is different from Example 1 in that the chain extender in step S3 is selected from neopentyl glycol; the raw materials of regenerated polyester fibers and regenerated cotton The mass ratio of fiber raw material, chain extender, cetyl phosphate salt, and polyethylene glycol is 2:0.6:0.78:0.025:0.18; the multiple of wet-heat drafting is 2.4; clean water is used for washing and drying, and the washing temperature is 47°C, and the drying temperature is 118°C.

[0044] Performance Testing

[0045] The performance test of the regenerated polyester long fibers prepared in Examples 1-3 shows that the volume resistivity reaches 1.8-2.2×10 8 Ω.cm, the moisture regain reaches 1.28~1.39% under the relative humidity of 60%, the breaking strength reaches 5.63~5.82cN / dtex, and the antistatic property, hygroscopicity and breaking strength are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap