Low-concentration particle-stabilized switching pickering emulsion and preparation method thereof

A low-concentration, granular technology, applied in the field of Pickering emulsions, can solve the problem of difficulty in the dosage of solid emulsifiers, and achieve the effect of good pH responsiveness and hydrophilic and hydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of a low-concentration particle-stable switching Pickering emulsion, comprising the following steps:

[0031] Disperse 0.8-2g nano-silica nanoparticles in ethanol, preferably 1g nano-silica nanoparticles, add 0.8-3ml silane coupling agent, preferably 1ml silane coupling agent, stir at 55-65°C for 4 After ~6h, centrifuge to obtain the modified nano-silica intermediate product, preferably 65°C, 4h;

[0032] Disperse 1.5-3 g of the modified nano-silica intermediate product and 0.2-1.0 g of acid anhydride in chloroform respectively, preferably 0.5 g of the modified nano-silica intermediate product, preferably 2 g of acid anhydride. Heating to 45-55°C, preferably 50°C, then adding chloroform in which the modified nano-silica intermediate product is dispersed to react for 4-6 hours, preferably 4 hours, centrifugal washing and drying to obtain modified nano-silica particles;

[0033] Disperse the modified nano-silica particles in the oil phase, disperse t...

Embodiment 1

[0042] S1. Preparation of Nano-Silica Particles (SN)

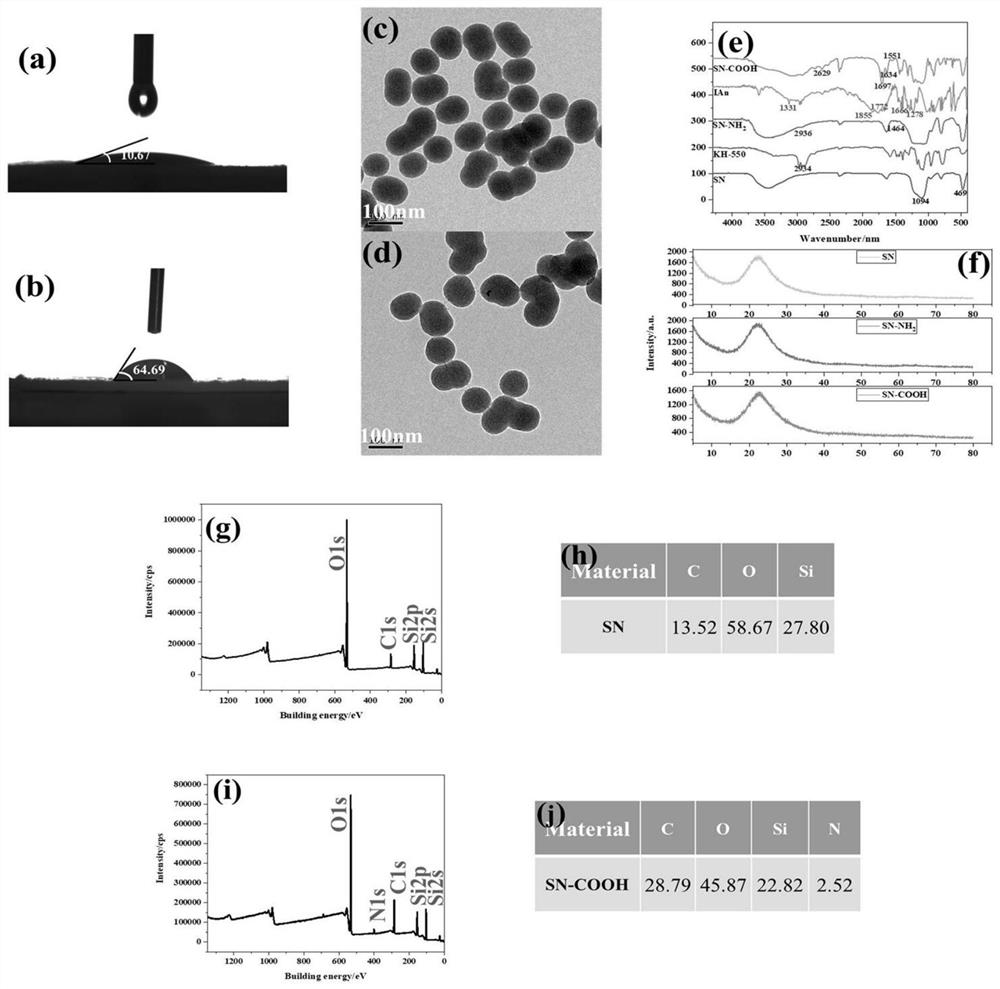

[0043] Mix 300 ml of ethanol, 75 ml of deionized water, 16.8 ml of 25wt% ammonia water and TX-100, and stir at room temperature for 30 minutes; then add 12.8 g of ethyl orthosilicate, and stir at room temperature for 12 hours; Contact angle test, TEM, FTIR, XRD and XPS for SN characterization, the results are as follows figure 1 shown.

[0044] S2. Preparation of modified nano-silica particles (SN-COOH)

[0045] Add 1 g of silica nanoparticles to 10 ml of ethanol and stir for 10 min. Then 1 ml of γ-aminopropyltriethoxysilane (KH-550) was added, and the mixture was stirred at 65° C. for 4 h. After the reaction, the product was centrifuged and washed three times with ethanol solution. Finally, the pure modified nano-silica intermediate (SN-NH) was obtained by centrifugation. 2 ). 2g itaconic anhydride (IAn) and 0.5g SN-NH 2 Disperse into 25ml of chloroform respectively.

[0046] First, add the chloroform solution of it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com