Drying agent with heavy metal removal function and preparation method thereof

A desiccant and heavy metal technology, applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of inability to achieve effective adsorption of heavy metals, corrosiveness of the esophagus, low moisture absorption rate of silica gel, etc., and achieve good complexation ability , Large desorption capacity and fast desorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

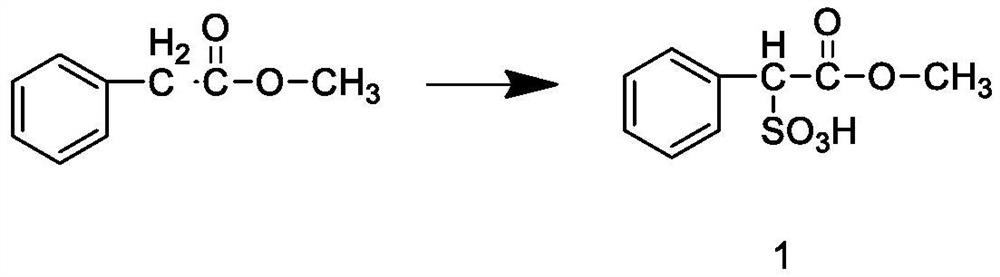

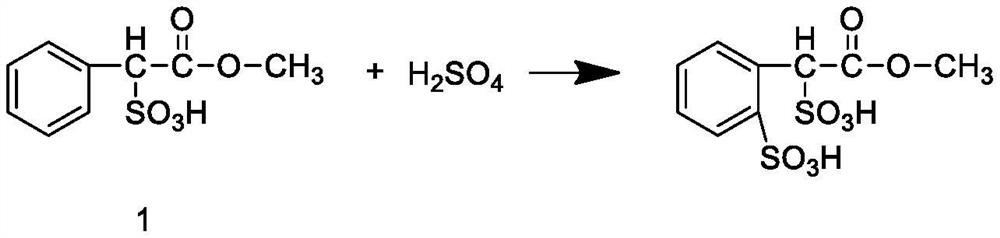

Method used

Image

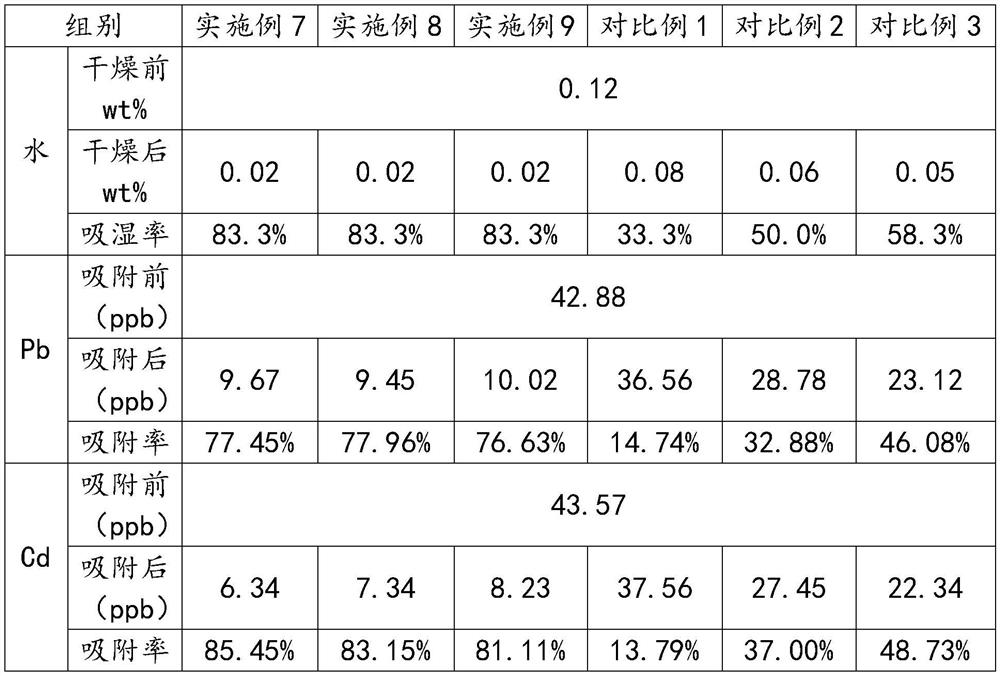

Examples

Embodiment 1

[0037] Preparation of silica nanopowder:

[0038] Step S1, add 30.5mL of deionized water, 120.4mL of 2mol / L hydrochloric acid solution and 4.1g of P123 into the three-necked flask, raise the temperature to 40°C and stir until dissolved, add 8.8g of tetraethyl orthosilicate to it, stir evenly, and let stand 18h, then heated up to 95°C for 24h, filtered, the filter cake was washed and dried to obtain mesoporous silica;

[0039] Step S2, add 0.2g of mesoporous silica, 30mL of toluene and 0.1g of phosphorus oxychloride to the autoclave, react at 140°C for 3h, filter, wash and dry the filter cake to obtain silica nanopowder.

Embodiment 2

[0041] Preparation of silica nanopowder:

[0042] Step S1, add 30.8mL of deionized water, 120.6mL of 2mol / L hydrochloric acid solution and 4.2g of P123 into the three-necked flask, raise the temperature to 40°C and stir until dissolved, add 8.9g of tetraethyl orthosilicate to it, stir evenly, and let stand 20h, then heated up to 95°C and kept for 24h, filtered, the filter cake was washed and dried to obtain mesoporous silica;

[0043] Step S2, add 0.25g of mesoporous silica, 35mL of toluene and 0.1g of phosphorus oxychloride into the autoclave, react at 150°C for 3h, filter, wash and dry the filter cake to obtain silica nanopowder.

Embodiment 3

[0045] Preparation of silica nanopowder:

[0046] Step S1, add 31.2mL of deionized water, 120.8mL of 2mol / L hydrochloric acid solution and 4.3g of P123 into the three-necked flask, raise the temperature to 40°C and stir until dissolved, add 9g of ethyl orthosilicate to it, stir well, and let it stand for 22h , and then heated to 95 ° C for 24 hours, filtered, and the filter cake was washed and dried to obtain mesoporous silica;

[0047] Step S2, add 0.3g of mesoporous silica, 40mL of toluene and 0.12g of phosphorus oxychloride into the autoclave, react at 160°C for 4h, filter, wash and dry the filter cake to obtain silica nanopowder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com