Multipurpose composite cloth with protection performance, preparation method and application thereof

A protective performance and composite cloth technology, applied in the direction of protective equipment, protective equipment, applications, etc., can solve the problems that are not conducive to reducing the back convex deformation of the product, non-penetrating damage to the human body, and increase production costs, so as to achieve uniform bonding , soft properties, the effect of promoting wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

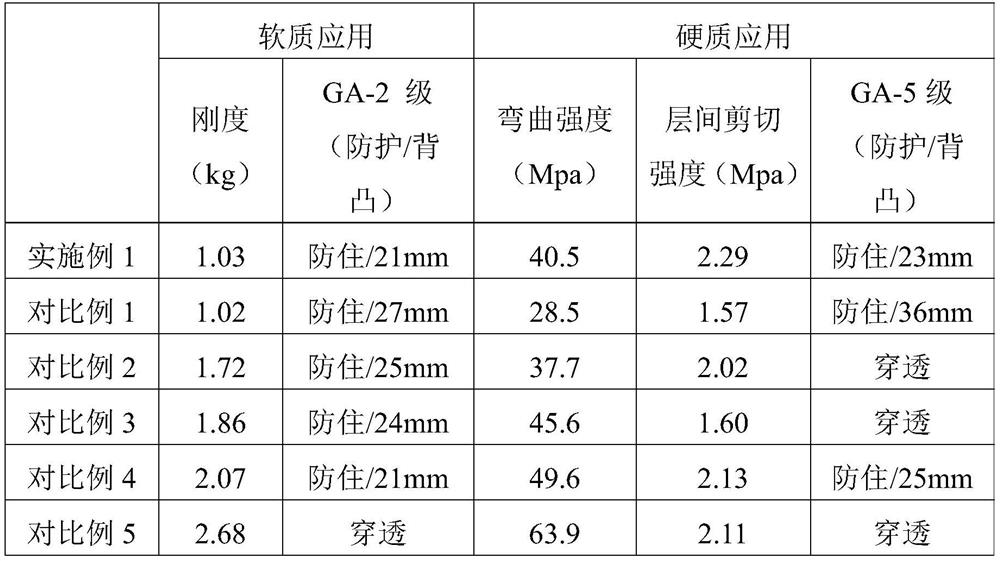

Examples

preparation example Construction

[0027] The invention provides a method for preparing a multipurpose composite cloth with protective properties, the method comprising the following steps:

[0028] 1) Leading high-strength and high-modulus fibers from the creel to make a fiber layer arranged in parallel and straight in one direction, and soaking the fiber layer in a compounded water-based adhesive to obtain a fiber layer containing glue;

[0029] 2) Evaporating part of the water in the glue-containing fiber layer, and then attaching a mesh film as a carrier to one side of the glue-containing fiber layer, drying it below 100°C and then cooling to obtain a unidirectional non-woven fabric;

[0030] 3) At a temperature lower than the melting temperature of the mesh adhesive film, two layers of unidirectional non-weft fabrics are laminated orthogonally to obtain a composite cloth, and in the composite cloth, the mesh adhesive of the two layers of unidirectional non-weft fabrics Membranes are located on the outside....

Embodiment 1

[0038] Preparation of a kind of ultra-high molecular weight polyethylene fiber bulletproof composite material:

[0039] 1) Mix the water-based styrene-isoprene-styrene aqueous dispersion and the acrylic emulsion at a ratio of 1:1, and then add a polyether-modified trisiloxane wetting agent according to 2 / 1000 of the weight of the mixed emulsion, After mixing and stirring for half an hour, a compound water-based adhesive was prepared with a viscosity of 100 cps;

[0040] 2) Arranging commercially available ultra-high molecular weight polyethylene fibers in parallel in one direction to form a fiber layer arranged in parallel in one direction;

[0041] 3) Infiltrate the polyethylene fiber layer arranged in parallel in one direction with the compounded water-based adhesive to control the amount of glue applied, and then go out of the oven and pass through the hot roller to evaporate part of the water at a temperature of 95°C to make the compounded water-based adhesive The adhesiv...

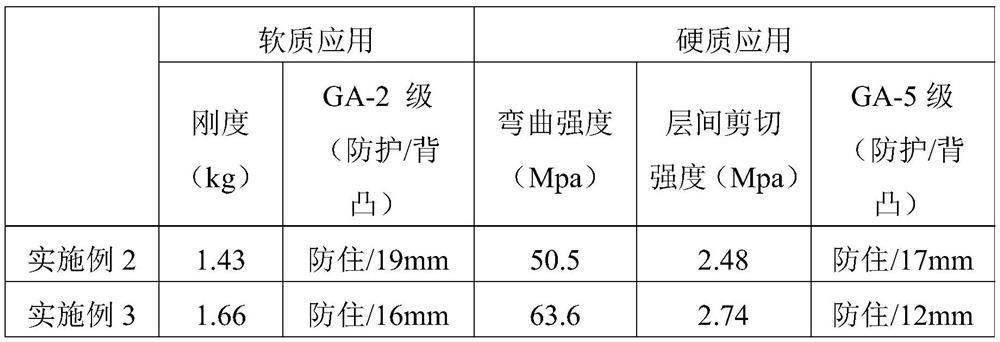

Embodiment 2

[0064] A kind of preparation of aramid fiber bulletproof composite material:

[0065] 1) Mix the water-based styrene-isoprene-styrene aqueous dispersion and the acrylic emulsion at a ratio of 4:1, and then add a polyether-modified trisiloxane wetting agent according to 3 / 1000 of the weight of the mixed emulsion, After mixing and stirring for half an hour, a compound water-based adhesive was prepared;

[0066] 2) arranging commercially available aramid fibers in parallel in one direction to form a fiber layer arranged in parallel in one direction;

[0067] 3) The above-mentioned aramid fiber layer arranged in parallel in one direction is soaked with the compounded water-based adhesive to control the amount of glue applied, and then it is taken out of the oven and passed through a hot roller to evaporate part of the water at a temperature of 85°C to make the compounded water-based adhesive The adhesive initially forms a film and produces a certain viscosity;

[0068] 4) Set th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com