Sulfur-containing ferritic stainless steel and manufacturing method thereof

A manufacturing method and stainless steel technology, applied in the field of stainless steel smelting and hot working, can solve the problems of poor transverse mechanical properties of free-cutting ferritic stainless steel, and achieve the effects of improving transverse mechanical properties, prolonging tool life and obvious spheroidizing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

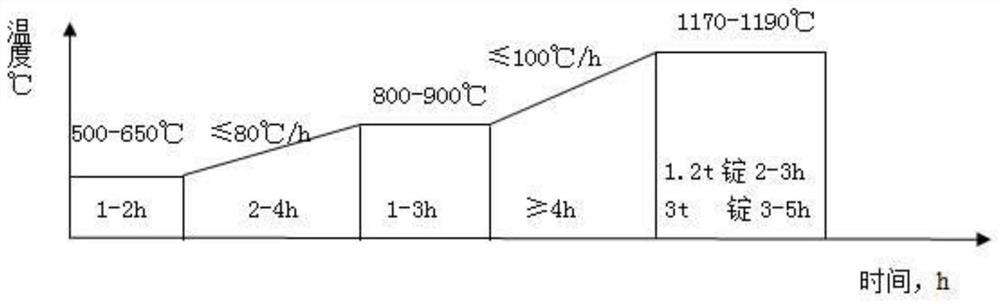

[0099] The present embodiment provides a manufacturing method of sulfur-containing ferritic stainless steel: the manufacturing method includes the following steps:

[0100] (1) Electric furnace primary smelting process: heating and melting raw materials to obtain primary molten steel.

[0101] (2) LF refining process: adding a slag-forming material and a deoxidizer to the primary molten steel to obtain a refined molten steel. According to the mass percentage, the refined molten steel includes the following chemical components: C: 0.15, Si: 0.30, Mn: 1.25, P: 0.025, S: 0.20%, Cr: 16.5, Ni: 0.40; Mo: 0.40; V: 0.10.

[0102] (3) VD degassing process: First, the refined molten steel is hoisted to the VD station, evacuated to 0.2 Torr, the temperature is controlled at 1650°C, the vacuum degree requirement: 67Pa, the vacuum holding time is 15min, and the total vacuum time is 25min.

[0103] Then, break the vacuum, feed the tellurium alloy cored wire into the wire feeding machine a...

Embodiment 2

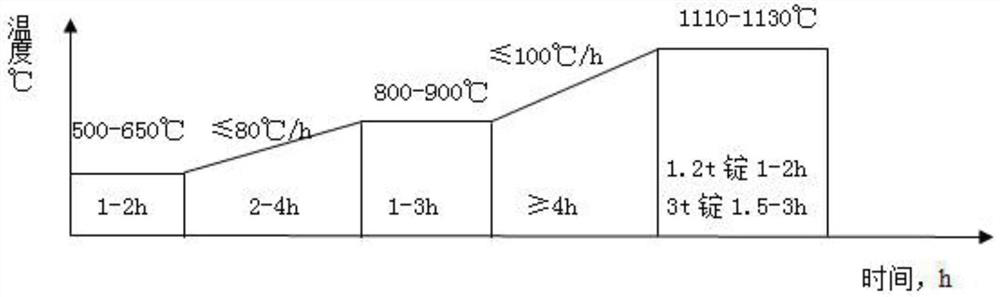

[0127] This embodiment provides a method for manufacturing sulfur-containing ferritic stainless steel. The process of the manufacturing method is the same as that of Embodiment 1, and the difference is only in raw material components and quenching and tempering process parameters. According to the mass percentage, the billet in this implementation contains the following chemical composition: C: 0.16%; Si: 0.42%; Mn: 1.25%; P: 0.017%; S: 0.21%; Cr: 16.4%; Ni: 0.45%; Mo: 0.44%; V: 0.11%; Te: 0.025%; Ca: 0.025%. The diameter of the billet is 135×145.

[0128] In this example, by changing the process parameters of the quenching and tempering process, the properties of the sulfur-containing ferritic stainless steel samples prepared under different quenching and tempering process parameters were tested, as shown in Table 2. In the quenching process, the specific changes are the heating temperature and holding time of the fifth stage. In the tempering process, the specific changes a...

Embodiment 3

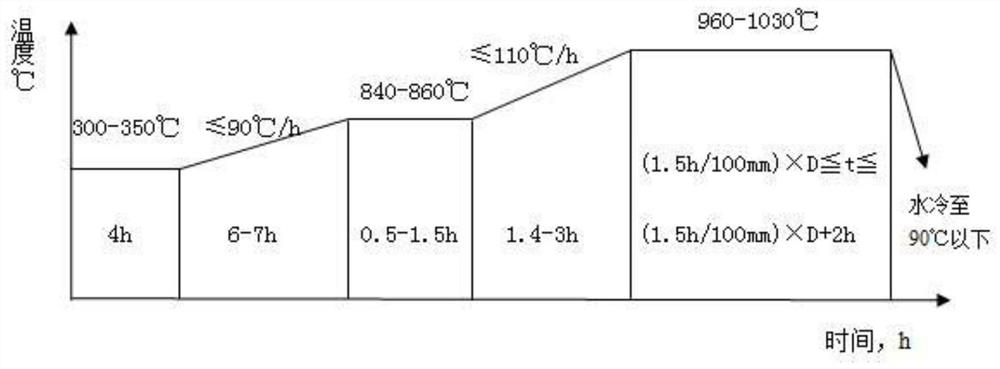

[0134] This embodiment provides a method for manufacturing sulfur-containing ferritic stainless steel. The process of the manufacturing method is the same as that in Embodiment 1, and the difference is only in the composition of the raw materials.

[0135] In this example, experimental design schemes with different formulations were adopted to test the properties of sulfur-containing ferritic stainless steel samples prepared under different experimental formulations, as shown in Table 3 and Table 4.

[0136] The mass percent of each chemical element in the steel of table 3 embodiment 3.1-3.9

[0137] Numbering C Si mn P S Cr Ni Mo V Ca Te Example 3.1 0.12 0.30 1.25 0.025 0.16 16.5 0.40 0.40 0.10 0.04 0.01 Example 3.2 0.12 0.30 1.25 0.025 0.20 16.5 0.40 0.40 0.10 0.04 0.03 Example 3.3 0.12 0.30 1.25 0.025 0.26 16.5 0.40 0.40 0.10 0.04 0.05 Example 3.4 0.17 0.30 1.25 0.025 0.20 16.5 0.40 0.40 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com