Passivation solution used for trivalent chromium passivation of high-silicon die-casting aluminum alloy and passivation method

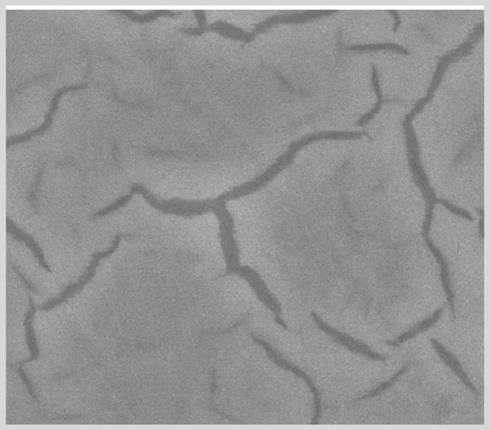

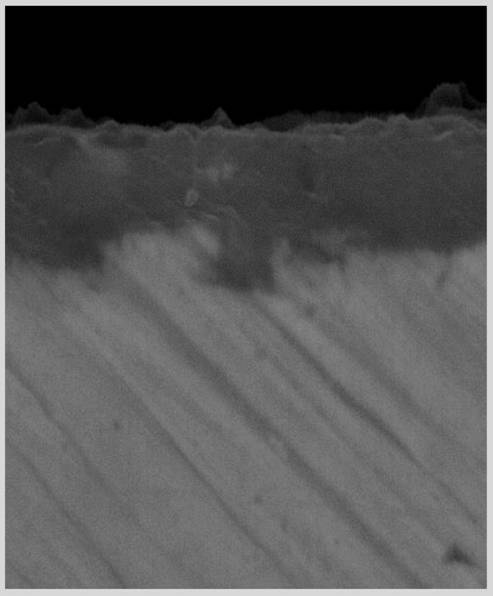

A technology of casting aluminum alloy and trivalent chromium, which is applied in the coating process of metal materials, etc., can solve the problems of unsatisfactory corrosion resistance, achieve good corrosion resistance, facilitate wastewater treatment, and promote the effect of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

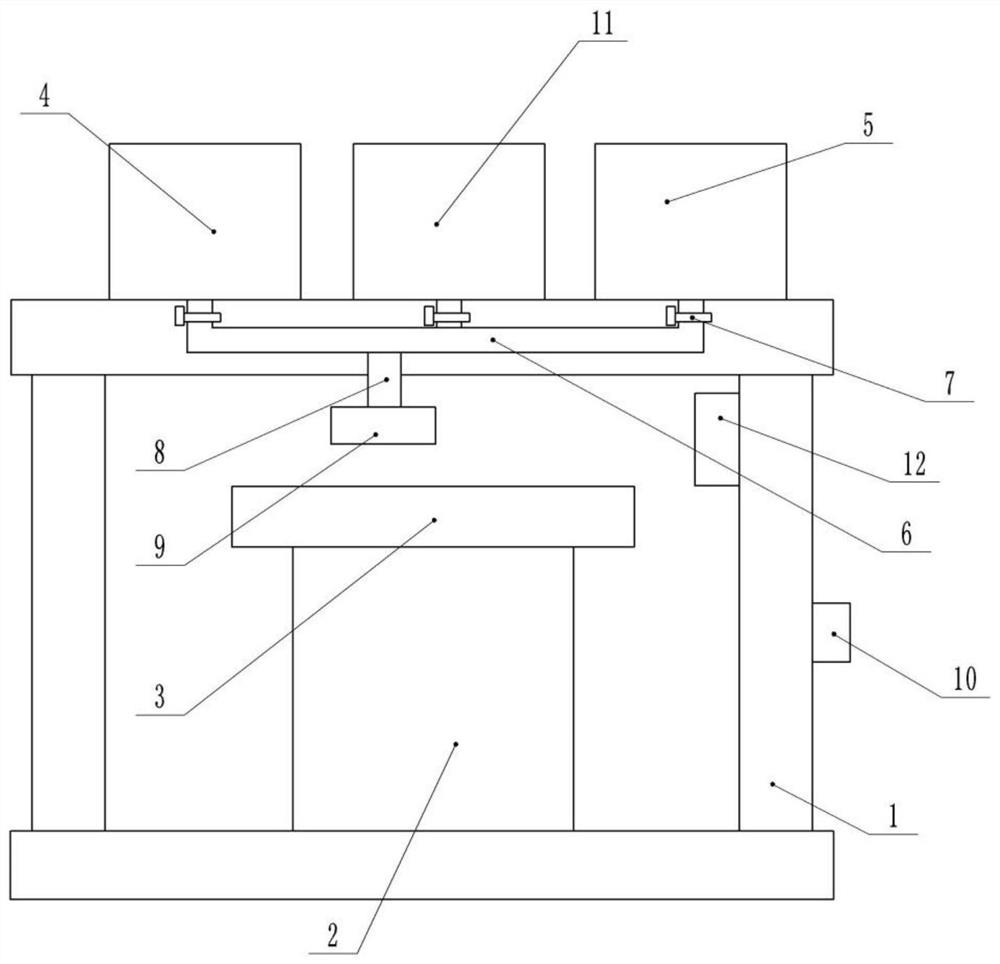

Method used

Image

Examples

Embodiment 1

[0035] The passivation solution used for the passivation solution of trivalent chromium passivation of high-silicon die-casting aluminum alloys includes: 3-10 g / L of chromium nitrate (8 g / L of chromium nitrate in this embodiment), 2-8 g of organic acid complexing agent / L (organic acid complexing agent 6g / L in this embodiment), polyhydric alcohol complexing agent 1~6g / L (polyhydric alcohol complexing agent 3g / L in this embodiment), corrosion resistant agent 1~3g / L (corrosion resist 1g / L in this embodiment), film-forming accelerator 1-3g / L (film-forming accelerator 2g / L in this embodiment).

[0036] Chromium nitrate can be used as the main film-forming salt, and can also provide nitrate ions for oxidation. This technical scheme uses nitrate ions in chromium nitrate as an oxidant to produce oxidation and promote film formation, that is, the film-forming main salt and oxidant Combining two into one; the combination of organic acid and polyhydric alcohol two complexing agents, in...

Embodiment 2

[0051] Embodiment 2: The difference between this embodiment and Example 1 is that the chromium nitrate content is 8g / L, the lanthanum nitrate content is 3g / L, the zirconium nitrate content is 0g / L, and the cerium nitrate content is 0g / L, and all the other conditions are same.

Embodiment 3

[0052] Embodiment 3: The difference between this embodiment and Example 1 is that the chromium nitrate content is 8g / L, the lanthanum nitrate content is 2g / L, the zirconium nitrate content is 0g / L, and the cerium nitrate content is 0g / L, and all the other conditions are same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com