Aluminium alloy trivalent chromium passivation solution as well as preparation method and passivation technology thereof

A technology of passivation solution and trivalent chromium, which is applied in the coating process of metal materials, etc., can solve the problems of improving corrosion resistance and reducing costs, and achieves the effects of reducing production costs, reducing prices, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

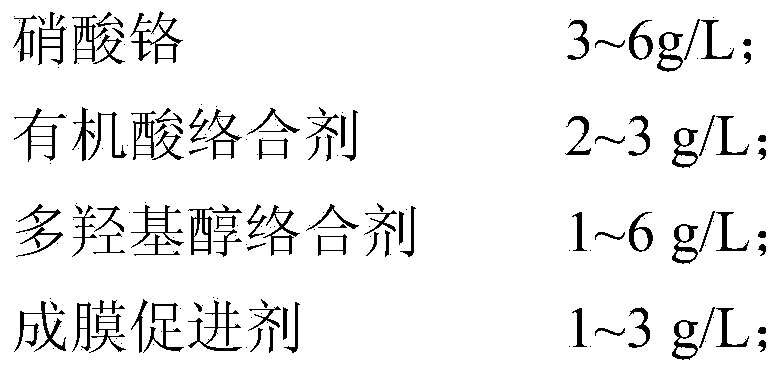

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of aluminum alloy trivalent chromium passivation solution of the present invention is as follows:

[0039] The raw materials required for configuration are all from commercially available products. Weigh the chromium nitrate raw material according to the proportion, add appropriate amount of water to dissolve, then add the first group of complexing agent organic acid, stir to dissolve, then add the second group of complexing agent polyhydric alcohol, stir to dissolve , add water to a certain concentration, heat the solution to 50~70°C and keep it warm for 2 hours, then add the film-forming accelerator, stir to dissolve, and get the passivation solution after standing still.

[0040] The passivation process flow using passivator of the present invention is as follows:

[0041] Degreasing (degreasing) - hot water washing (two flows) - activation - water washing (two processes) - passivation - water washing - hot water washing - drying.

[0042] In ...

Embodiment 1

[0049] Prepare passivation solution:

[0050] Select chromium nitrate as the main film-forming salt, first dissolve chromium nitrate at a concentration of 6 g / L with an appropriate amount of water, then add 4 g / L of malic acid, stir to dissolve, then add 4 g / L of glycerol, stir to dissolve, Heat the solution to 50°C and keep it warm for 2 hours, then add nickel nitrate 3 g / L and stir to dissolve, and then passivation solution is obtained after standing still.

[0051] Passivation process:

[0052] Degrease the passivated workpiece, wash with 20 g / L sodium silicate and 3 mL / L OP-10 emulsifier at a temperature of 50°C; use 10 mL / L hydrofluoric acid and react for 5 seconds at room temperature Activation; two water washes again; passivation at room temperature for 2 minutes using the passivator of the example; then water washing and hot water washing, followed by drying.

[0053] The various process parameters of the above-mentioned passivated workpiece are: the surface of the w...

Embodiment 2

[0055] Prepare passivation solution:

[0056] Select chromium nitrate as the main film-forming salt, first dissolve chromium nitrate at a concentration of 8 g / L with an appropriate amount of water, then add 6 g / L oxalic acid, stir to dissolve, then add glycerin 3 g / L, stir to dissolve, and Heat the solution to 55°C and keep it warm for 2 hours, then add 2 g / L of nickel nitrate and stir to dissolve it, and then obtain the passivation solution after standing still.

[0057] Passivation process:

[0058] Degrease the passivated workpiece, use sodium silicate 40g / L, OP-10 emulsifier 3ml / L to wash at 60°C; use hydrofluoric acid 10ml / L, react at room temperature for 20 seconds Activation; two water washes again; using the passivator of this example, passivation at room temperature for 1 minute; then washing with water and then hot water and then drying.

[0059] The various process parameters of the workpiece after the above-mentioned passivation are:

[0060] The surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com