LED lamp with high-heat-dissipation nano coating

A nano-coating, LED lamp technology, used in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., can solve the problem of difficult heat dissipation of metal materials, low surface thermal emissivity, Heat accumulation and other problems to achieve the effect of improving heat dissipation performance, large specific surface area, and enhanced radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the objects, technical solutions, and advantages of the present invention more clear, the technical solutions in the embodiments in the embodiments will be described in contemplation in conjunction with the drawings in the embodiment of the present invention.

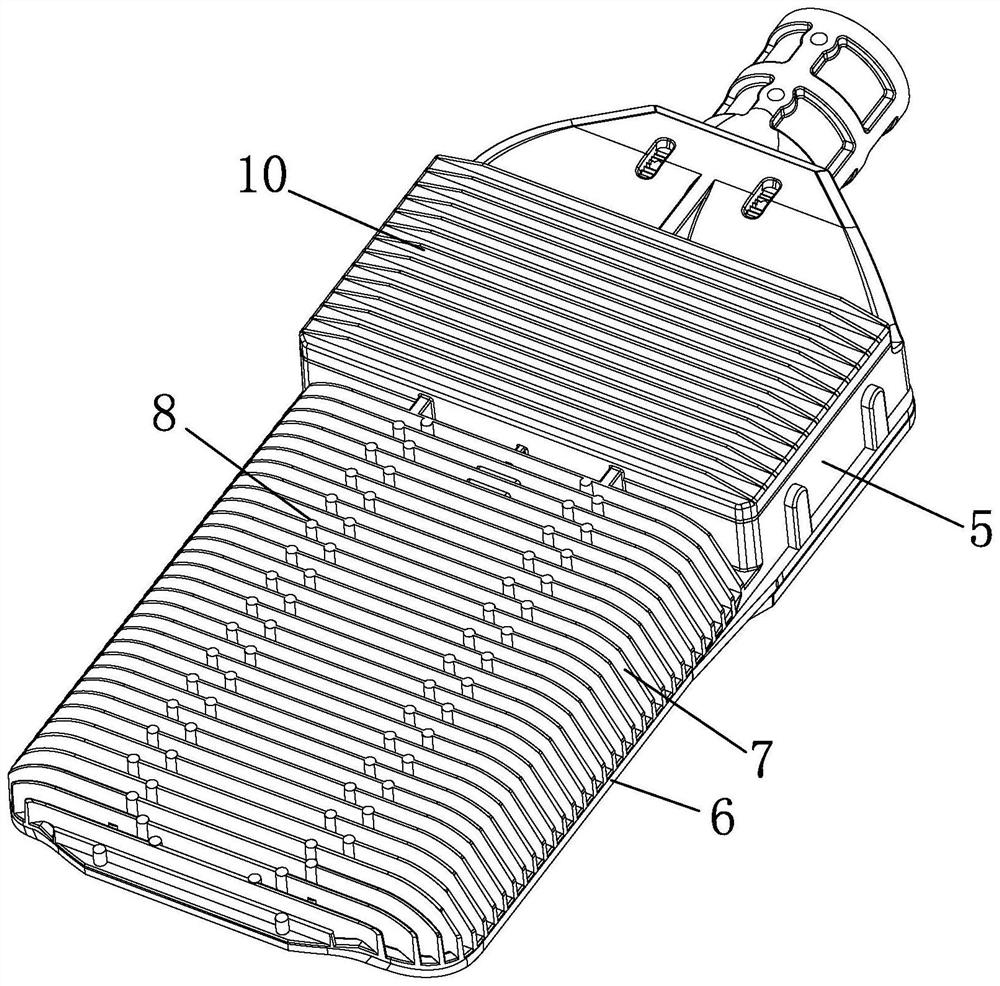

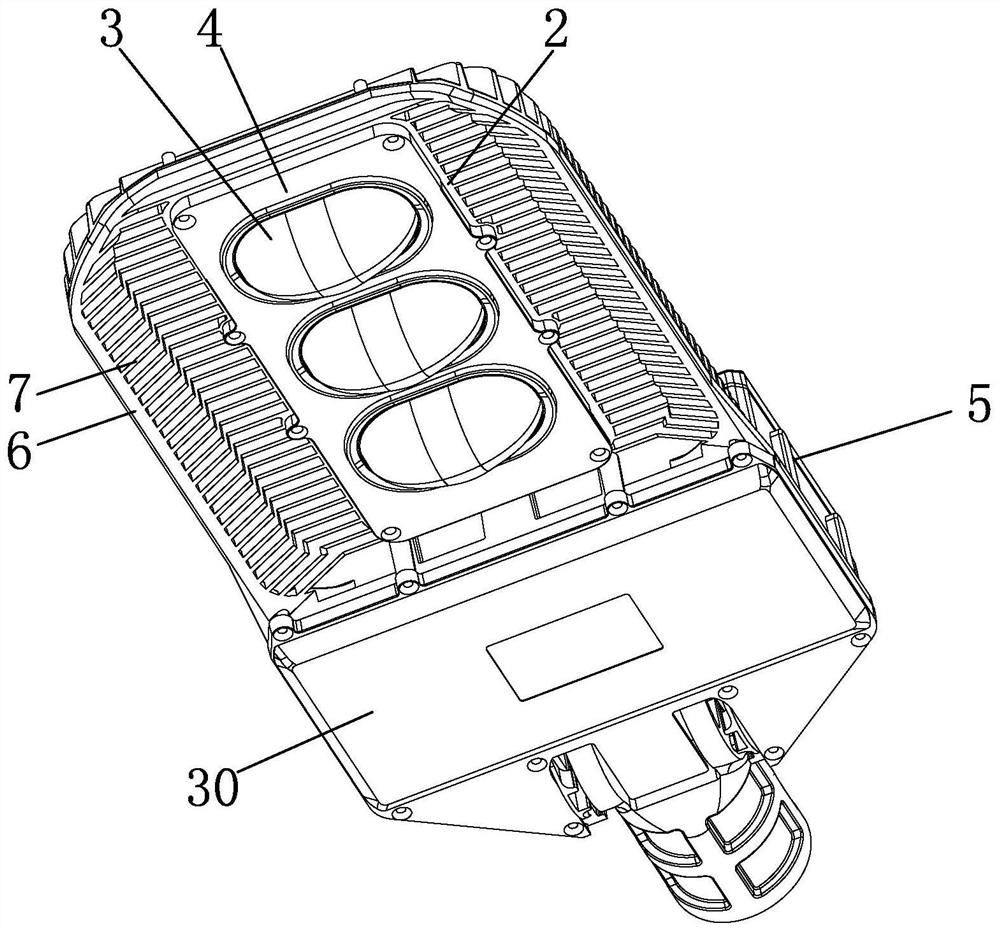

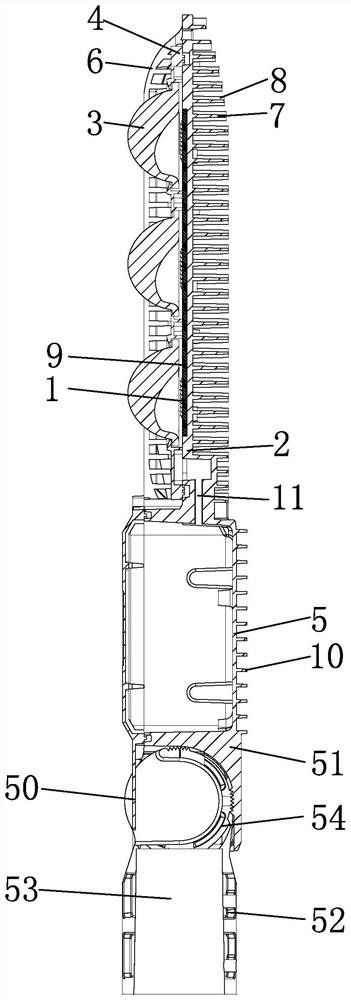

[0023] Refer Figure 1-5 A coating having a high heat dissipation nanometer LED lamp comprising a light source for emitting an LED lamp for mounting the LED lamp 2 of the base 1, heat radiating fins for heat dissipation, the cover provided in the LED lamp 1 the lens 3, the cover plate 4 and the fixed lens 3 disposed next to the base 2 of the electrical component mounting box 5, the heat dissipating fins comprises a connecting block 6, spaced at an upper end connected to the frame number of the fins 6 7 left and right ends of the heat radiation fins 7 are connected to opposite ends of the connection block 6, the intermediate form of the heat radiation fins 7 is suspended; 2 located in the base frame 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com