Device and method for detecting component concentration of mixed gas and application

A mixed gas and detection device technology, which is applied in the field of mixed gas component concentration detection devices, can solve the problems of limited application range, high cost, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

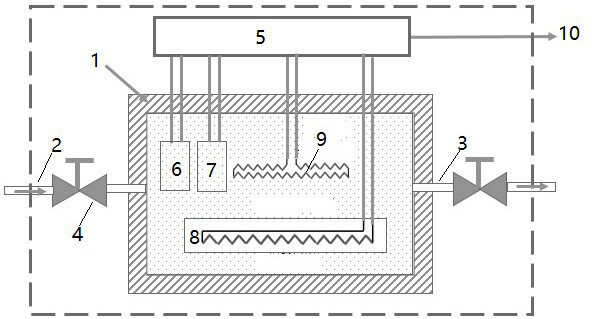

[0124] Such as figure 1 , a device for detecting the component concentration of a mixed gas. The measuring gas chamber 1 with a fixed volume is a cylinder made of Invar. The inner size of the container is Φ3cm×length 5cm. The inner surface of steel is smooth and clean, and it is made by welding process. The measuring gas chamber 1 is a closed chamber with an input pipe 2 and an output pipe 3. The input pipe 2 and the output pipe 3 are stainless steel pipes with a diameter of Φ3mm, and equipped with a miniature electric stop valve 4 to realize the opening of the input and output gases , Shut-off control, under the control of the controller 5, input 35.34ml of the mixed gas to be tested at 1 atmosphere into the measuring gas chamber 1, and output the gas to be tested after the test is completed. If the gas to be tested has no pressure, it is necessary to increase the suction pump to inhale the gas to be tested.

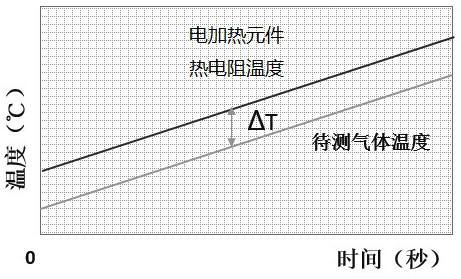

[0125] A micro MEMS gas pressure sensor 6 and a temperature sens...

Embodiment 2

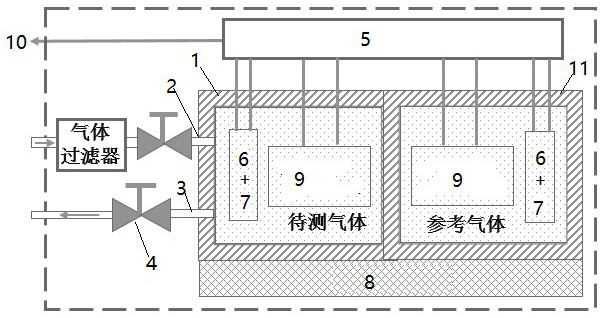

[0147] Such as figure 2 , a device for detecting the component concentration of a mixed gas, the measuring gas chamber 1 and the reference gas chamber 11 with a fixed volume are fired by ceramics, and the cavity is separated to form two sealed cavities (the measuring gas chamber and the reference gas chamber ), the inner surface of the cavity is smooth. Both cavities have a volume of 20ml, the internal dimensions of the container are 5cm in length x 2cm in width x 2cm, and the thickness of the ceramic is 2mm. The measuring gas chamber 1 is a closed chamber with an input pipe 2 and an output pipe 3. The input pipe 2 and the output pipe 3 are stainless steel pipes with a diameter of Φ2mm, and equipped with a miniature electric stop valve 4 to realize the opening of the input and output gases 1. Shut-off control, under the control of the controller 5, input 20ml of mixed gas to be tested at 1 atmosphere into the container, and output the gas to be tested after the test is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com