Composite sound absorption and noise reduction structure and preparation method thereof

A composite structure, sound-absorbing technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problem of difficult control of low-frequency noise, and achieve the effect of enhancing sound absorption, facilitating the dissipation of sound energy, and increasing reflection and scattering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

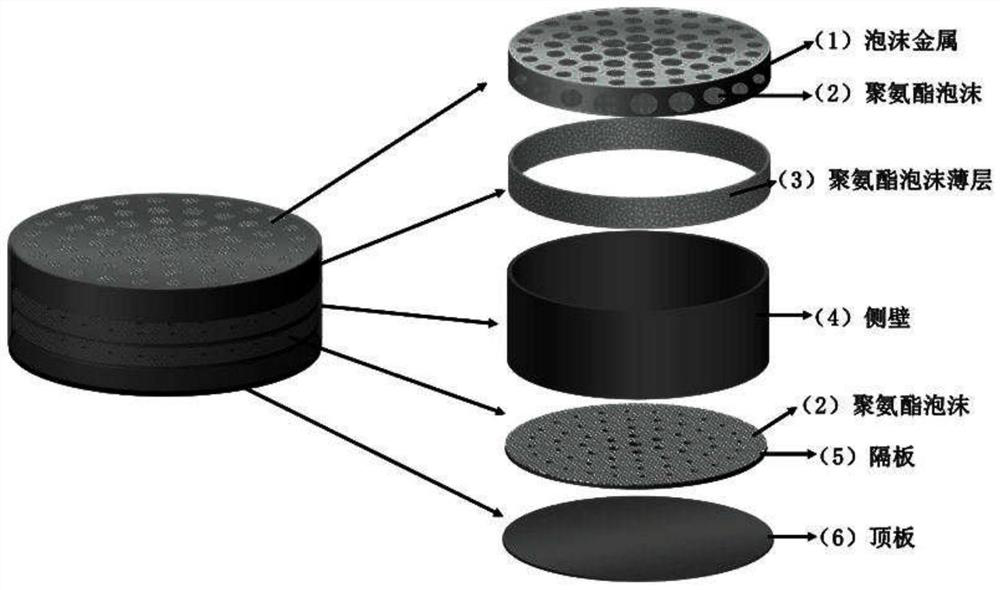

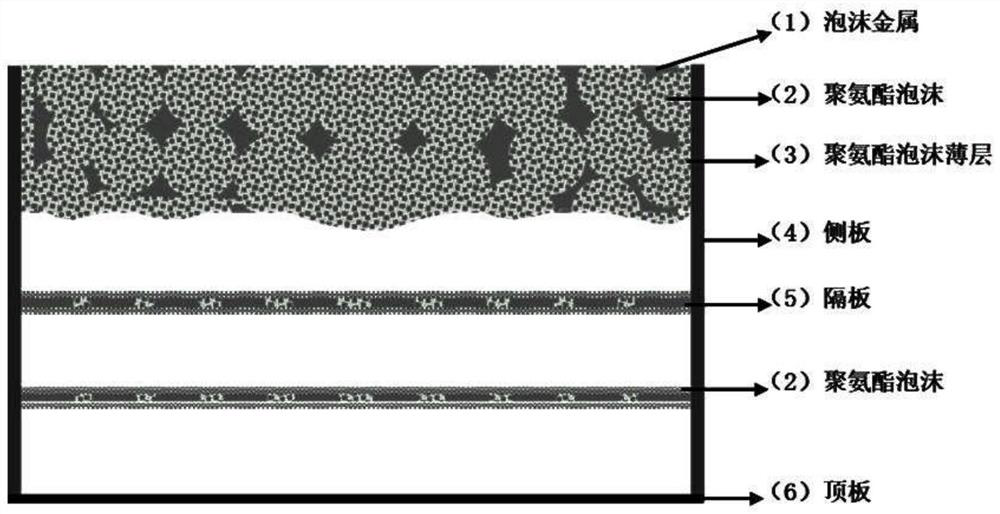

[0037] A composite sound-absorbing and noise-reducing structure whose overall appearance can be a cylinder or a cuboid. In this embodiment, taking the composite sound-absorbing and noise-reducing structure as a cylinder and the number of partitions as two as an example, the components of the composite sound-absorbing and noise-reducing structure and the spatial relationship of each component are given. figure 1 and figure 2 The three-dimensional structure schematic diagram and cross-sectional schematic diagram of the prepared composite sound-absorbing and noise-reducing structure are given respectively. The composite sound-absorbing and noise-reducing structure described in this embodiment includes open-cell foam metal 1 , polyurethane foam 2 , polyurethane foam thin layer 3 , sidewall 4 , partition 5 and top plate 6 . A "cavity" is formed between the polyurethane foam / metal foam interpenetrating composite structure, the side wall 4, and the top plate 6, and the "cavity" and...

Embodiment 2

[0039] Preparation of a composite sound-absorbing and noise-reducing structure (the composite sound-absorbing and noise-reducing structure is a cylinder, and the foam metal used is open-cell aluminum foam):

[0040] Before use, the open-cell aluminum foam is first put into a potassium hydroxide solution with a concentration of 2%, soaked at 60°C for 10 minutes, then placed in a hydrochloric acid solution with a concentration of 1%, soaked at 30°C for 4 minutes, and finally used Rinse with deionized water and dry. In parts by weight, weigh 60 parts of polyether polyol 330N, 40 parts of polymer polyol 36 / 28, 2 parts of deionized water, 1.8 parts of silicone oil, 0.6 parts of catalyst A33, 0.1 parts of catalyst A-1, 0.5 parts Parts of cross-linking agent diethanolamine in the container, as a white material. In parts by weight, weigh 45 parts of modified MDI in a container, which is a black material. Mechanically stir the components in the white material. After the components ar...

Embodiment 3

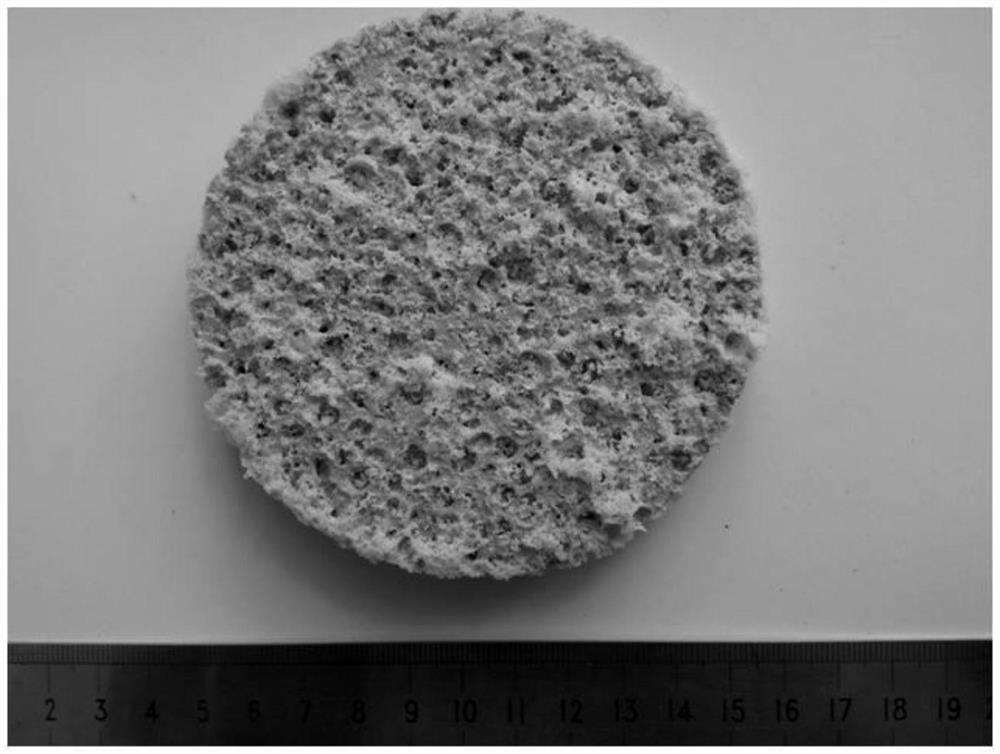

[0044] Sound absorption coefficient test of open-cell aluminum foam and polyurethane foam / metal foam interpenetrating composite structures:

[0045] In Example 3, the transfer function method was used to test the sound absorption coefficient of the prepared aluminum foam and polyurethane foam / metal foam interpenetrating composite structures. The test uses the SW series impedance tube (SW420), the diameter of the impedance tube is 100mm, and the test frequency range is 100-1600Hz. In order to obtain the accurate sound absorption coefficient of the sample, the diameter of the test sample should be the same as that of the impedance tube, and each sample should be tested 3 times, and the average value should be taken.

[0046] The sound absorption coefficient of open-cell aluminum foam and polyurethane foam / metal foam interpenetrating composite structure in embodiment 3 is as follows Figure 4 shown. The thickness of the open-cell aluminum foam used is thin (~1cm), the pore size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com