Preparation method of MOF film for supercapacitor electrode material

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of adverse effects on the stability of supercapacitor devices, hinder applicability, etc., to improve adhesion, delay peeling, Stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

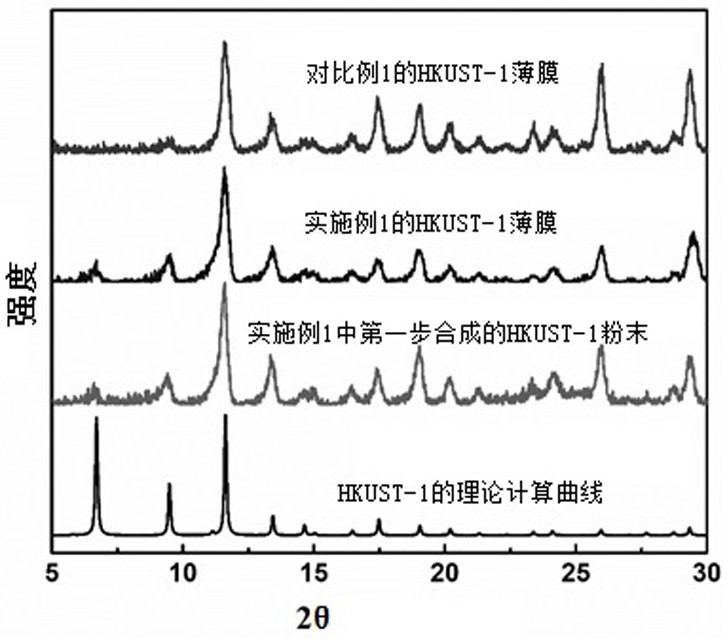

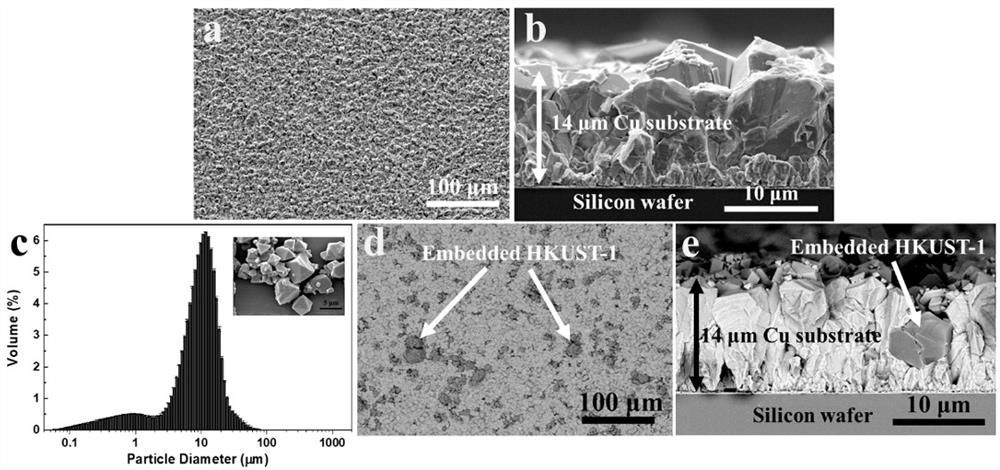

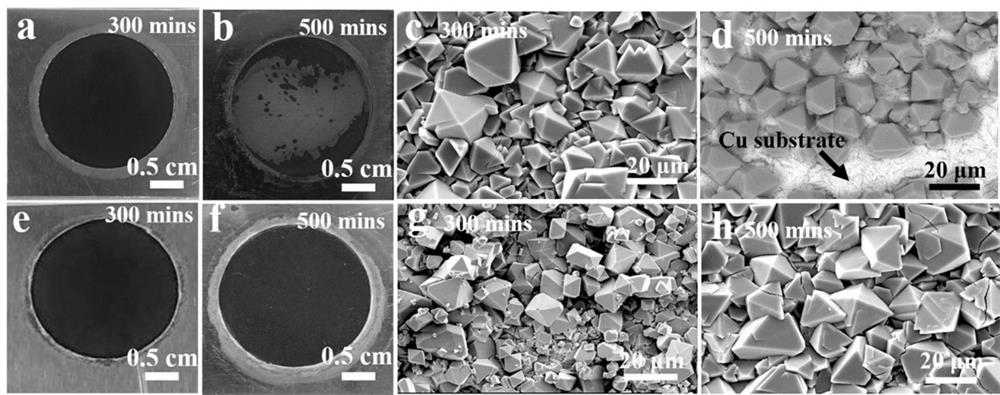

Embodiment 1

[0048] To prepare a film with high adhesion HKUST-1, the specific steps are as follows:

[0049] The first step is to synthesize HKUST-1 powder: use copper plates as the working electrode and counter electrode: take 67 mL absolute ethanol, 33 mL Milli-Q water, 2g H3BTC and 1g MTBS to configure the electrolyte. Using Autolab-PGSTAT-302N electrochemical workstation, at room temperature under magnetic field stirring, at 2-10mA cm -2 The constant current density was synthesized for a certain period of time. After the synthesis reaction, the blue synthesis solution was collected and allowed to stand for 2 hours, then the supernatant was decanted, and the precipitate was transferred to a 100mL polypropylene tube, and then added to the 100mL polypropylene tube 80 ml of ethanol, the precipitate was dispersed in absolute ethanol, and the supernatant was decanted after standing for 12 hours. The precipitate was washed with ethanol for three times, and then placed in a drying oven at 60°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com