Preparation method of novel integrated carbon fluoride positive electrode

A carbon fluoride and positive electrode technology, which is applied in the field of preparation of a new type of integrated carbon fluoride positive electrode, can solve problems such as limiting the energy density of lithium fluoride carbon batteries, increasing the proportion of inactive materials, and affecting the conductivity of carbon fluoride. Achieve the effects of improving electrode conductivity and electrolyte wettability, improving conductivity, and shortening the migration path of lithium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

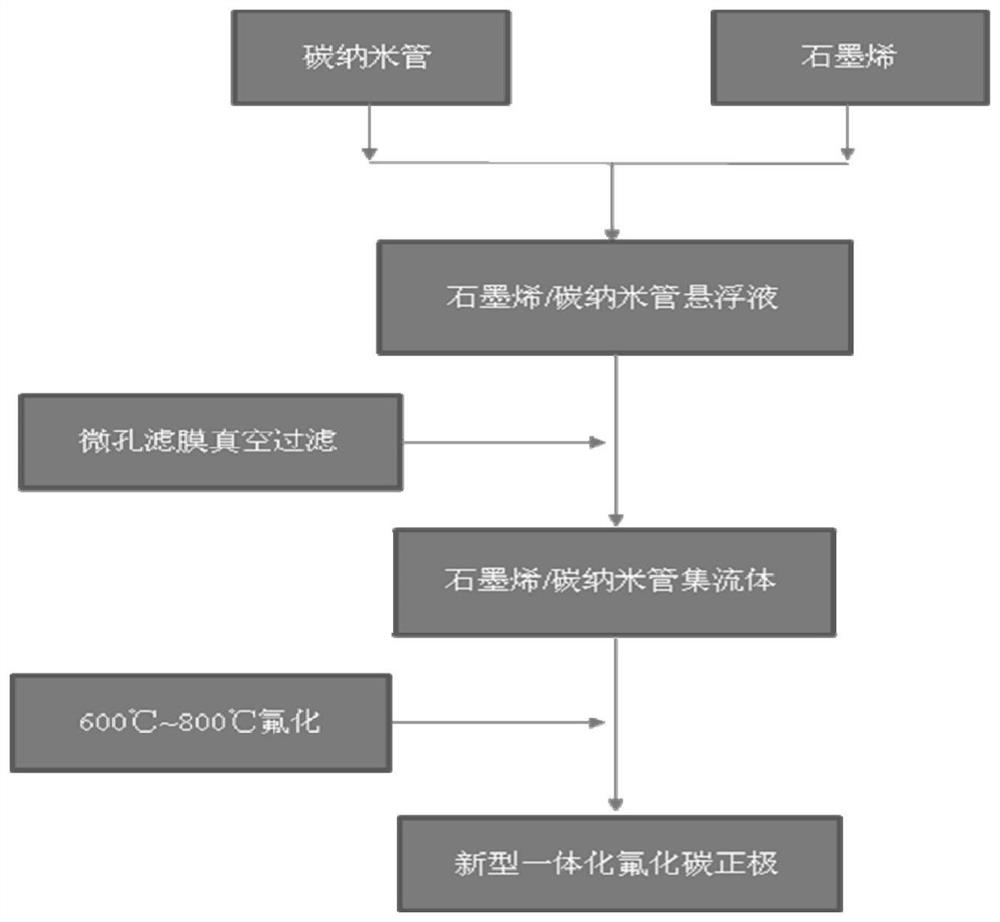

[0028] Embodiment 1: A kind of preparation method of novel integrated carbon fluoride positive electrode, such as figure 1 As shown, it specifically includes the following steps:

[0029] S1. Dispersion: Sieve multi-walled carbon nanotubes and multilayer graphene with 4 to 5 layers, and place them in 200ml (volume ratio 2:1) of ethanol+N,N-di Methylformamide (DMF) was dispersed in a beaker mixed with a dispersing solvent by a cell breaker with a dispersing power of 1500W and a dispersing time of 5min to form a graphene / carbon nanotube suspension with a concentration of 10mg / ml.

[0030] S2. Suction filtration: transfer the graphene / carbon nanotube suspension prepared in S1 to a filter equipped with a microporous membrane for vacuum filtration, wherein the diameter of the pores of the microporous membrane is 10 μm, and then filter the loaded The microporous filter membrane of the product is transferred to a vacuum oven for drying treatment, and the microporous filter membrane ...

Embodiment 2

[0032] Embodiment 2: A preparation method of a novel integrated carbon fluoride positive electrode, specifically comprising the following steps:

[0033] S1. Dispersion: sieve multi-walled carbon nanotubes and multilayer graphene, and place them in 500ml (volume ratio: 2:1) of methanol+N,N-dimethylformamide ( DMF) in a beaker with a mixed dispersion solvent, disperse by a cell wall breaker, the dispersion power is 500W, and the dispersion time is 30min to form a graphene / carbon nanotube suspension with a concentration of 1mg / ml.

[0034] S2. Suction filtration: transfer the graphene / carbon nanotube suspension prepared in S1 to a filter equipped with a microporous membrane for vacuum filtration, wherein the microporous membrane has a pore diameter of 5 μm, and then load the filter The microporous filter membrane of the product is transferred to a vacuum oven for drying treatment, and the microporous filter membrane is peeled off after drying to obtain a graphene / carbon nanotube...

Embodiment 3

[0036] Embodiment 3: A method for preparing a novel integrated carbon fluoride positive electrode, specifically comprising the following steps:

[0037] S1. Dispersion: Sieve multi-walled carbon nanotubes and multi-layer graphene, and place them in 300ml of N-methylpyrrolidinone+N,N-dimethyl with a volume ratio of 4:1 at a mass ratio of 1:1 Dimethylformamide (DMF) was mixed with a dispersing solvent in a beaker, and dispersed by a cell breaker with a dispersing power of 1000W and a dispersing time of 20min to form a graphene / carbon nanotube suspension with a concentration of 5mg / ml.

[0038] S2. Suction filtration: transfer the graphene / carbon nanotube suspension prepared in S1 to a filter equipped with a microporous membrane for vacuum filtration, wherein the microporous membrane has a pore diameter of 8 μm, and then load the filter The microporous filter membrane of the product is transferred to a vacuum oven for drying treatment, and the microporous filter membrane is peeled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com