Corrosion-resistant saw-blade-shaped alloy milling cutter

A corrosion-resistant and alloyed technology, applied in the field of saw blade-shaped alloy milling cutters, can solve the problems of inability to meet the needs of users, poor corrosion resistance, lack of wear resistance and mechanical properties, achieve good heat dissipation effect, promote common Deposition, life-extending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

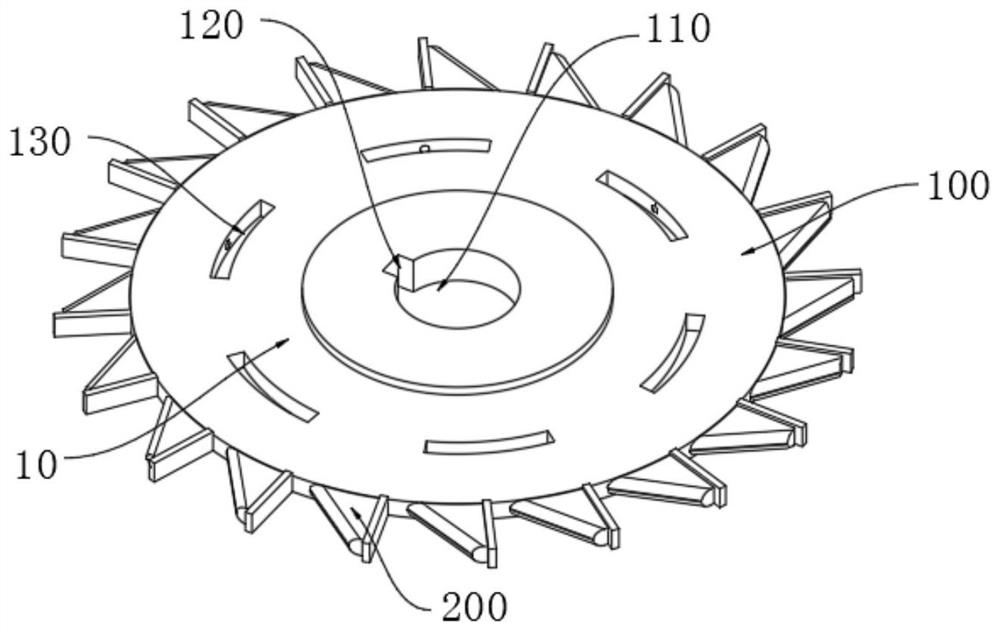

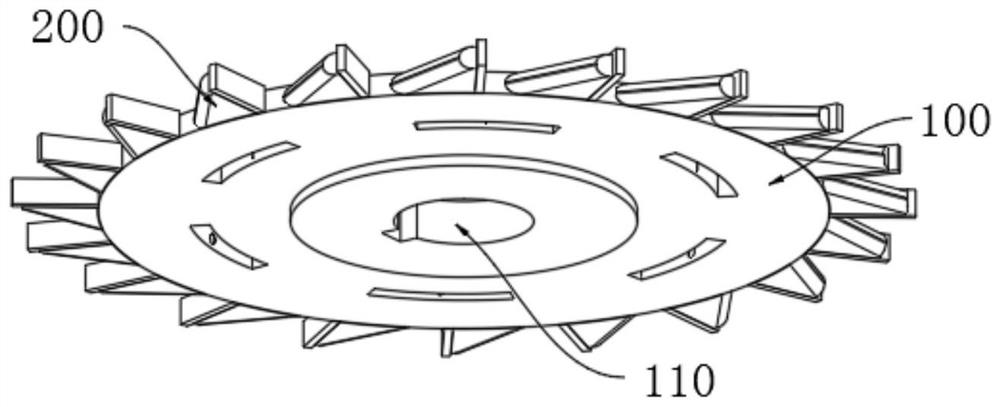

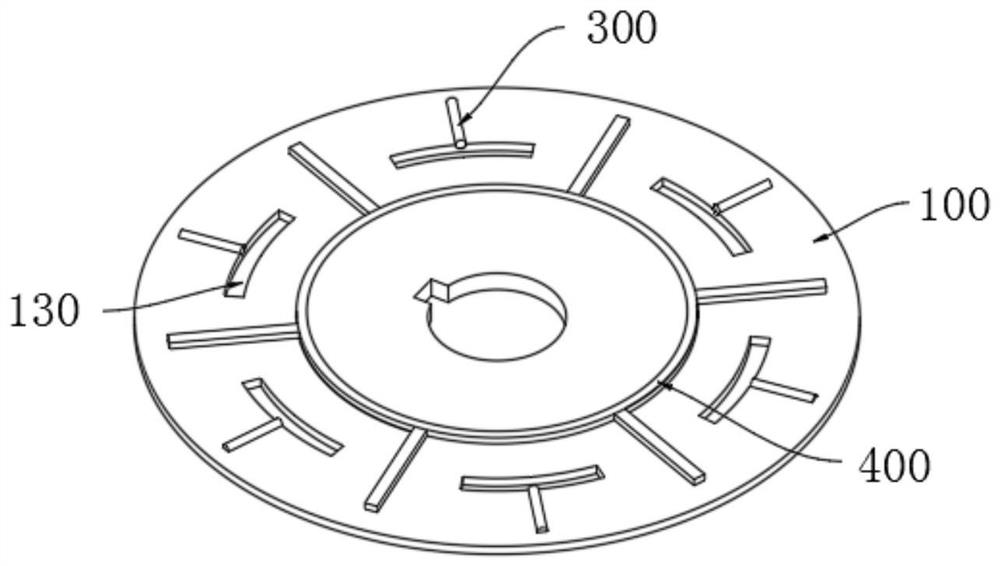

[0031] Please refer to Figure 1-5 As shown, a kind of corrosion-resistant saw blade-shaped alloy milling cutter comprises an alloy milling cutter body 10, and the alloy milling cutter body 10 includes a cutter head 100, and blades 200 are installed at equal intervals on the circumferential wall of the cutter head 100, and the cutter head 100 The center of the top is provided with an installation groove 110, and the inner wall of the installation groove 110 is provided with a pin groove 120, and the outer wall of the alloy milling cutter body 10 is deposited with a nanocomposite coating 20. In this embodiment, the installed installation groove 110 can realize For the installation of the alloy milling cutter body 10, the set pin groove 120 can prevent the alloy milling cutter body 10 from rotating during use, which improves the safety of the alloy milling cutter body 10 in use, and the deposited nanocomposite coating 20 can improve the alloy milling cutter body 10. The wear res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com