Flame-retardant slow-rebound memory sponge and preparation method thereof

A technology of memory foam and slow rebound, which is applied in the field of slow rebound sponge, can solve the problems of easy burning, thick smoke toxicity, and insufficient safety performance, and achieve the effect of less smoke and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

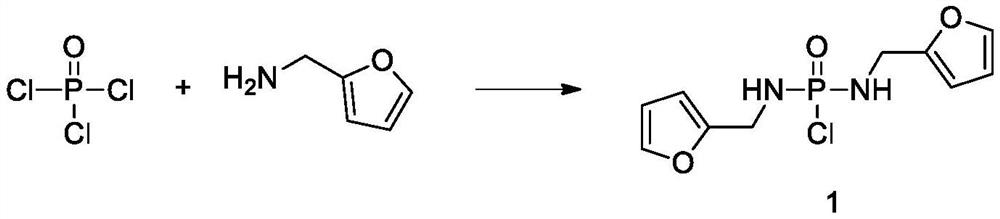

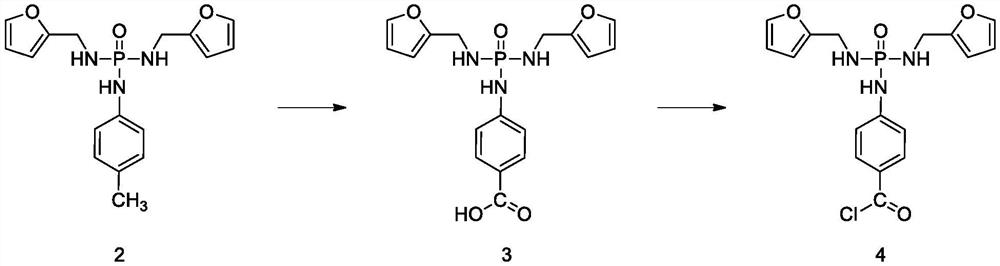

[0036] Prepare flame retardant, this flame retardant additive is made by following steps:

[0037] Step S1: under the conditions of ice bath and nitrogen protection, add 2-furylmethylamine and triethylamine into the flask, add chloroform, stir for 5min, then add the chloroform solution of phosphorus oxychloride dropwise to the flask, and then place in the ice bath React under the same conditions for 3 hours, then raise the temperature to 50°C to continue the reaction for 6 hours, after the reaction is completed, filter, wash with deionized water, and remove the solvent to obtain intermediate 1;

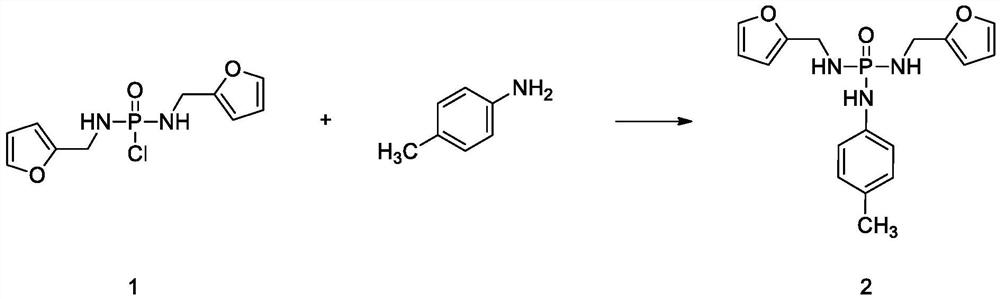

[0038] Step S2: Add p-aminotoluene and acetone into the flask, stir until dissolved at a temperature of 20°C under nitrogen protection, then add intermediate 1 into the flask, maintain the above conditions, react for 2 hours, and perform post-treatment. The steps are: rotary evaporation to remove the solvent, suction filtration, the filtrate was placed at 0°C for 5 hours, suction filt...

Embodiment 2

[0044] Prepare flame retardant, this flame retardant additive is made by following steps:

[0045] Step S1: under the conditions of ice bath and nitrogen protection, add 2-furylmethylamine and triethylamine into the flask, add chloroform, stir for 7.5min, then add the chloroform solution of phosphorus oxychloride dropwise in the flask, and then React under bath conditions for 3 hours, then raise the temperature to 50°C to continue the reaction for 6 hours, after the reaction is completed, filter, wash with deionized water, and remove the solvent to obtain intermediate 1;

[0046] Step S2: Add p-aminotoluene and acetone to the flask, stir until dissolved at a temperature of 22.5°C under nitrogen protection, then add intermediate 1 to the flask, maintain the above conditions, react for 2.5 hours, and perform post-treatment. The treatment steps are: rotary evaporation to remove the solvent, suction filtration, the filtrate was placed at 0°C for 5 hours, and suction filtration aga...

Embodiment 3

[0052] Prepare flame retardant, this flame retardant additive is made by following steps:

[0053] Step S1: under the condition of ice bath and nitrogen protection, add 2-furylmethylamine and triethylamine into the flask, add chloroform, stir for 10min, then add the chloroform solution of phosphorus oxychloride dropwise to the flask, and then place in the ice bath React under the same conditions for 3 hours, then raise the temperature to 50°C to continue the reaction for 6 hours, after the reaction is completed, filter, wash with deionized water, and remove the solvent to obtain intermediate 1;

[0054] Step S2: Add p-aminotoluene and acetone into the flask, stir until dissolved at a temperature of 25°C under nitrogen protection, then add intermediate 1 into the flask, maintain the above conditions, react for 3 hours, and perform post-treatment. The steps are: rotary evaporation to remove the solvent, suction filtration, the filtrate was placed at 0°C for 5 hours, suction filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com