Cleaning paraffin remover for oil field and preparation method of cleaning paraffin remover

A wax remover and cleaning technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of low oil production efficiency, high production cost, and many well cleaning times of oil wells, reducing the number of well cleaning, The effect of low production cost and extended well cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

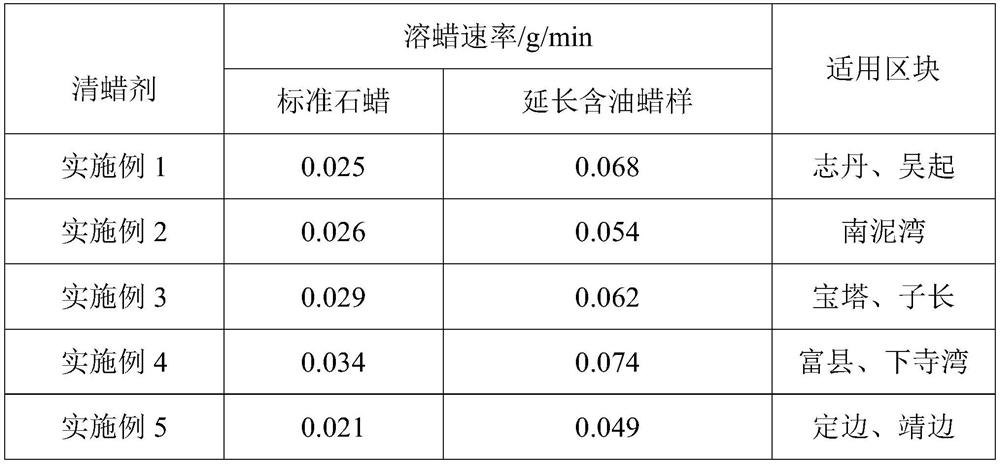

Examples

Embodiment 1

[0029] The present invention provides a kind of preparation method of cleaning wax remover for oil field, specifically implement according to the following steps:

[0030] Step 1, weigh the following components respectively according to mass percentage: OP-10 is 70kg, cetyltrimethylammonium chloride is 80kg, ethanol is 120kg, sodium salicylate is 30kg, water is 700kg, the above groups The sum of the weight percentages of the parts is 100%;

[0031] Step 2, adding 70kg of OP-10 weighed in step 1 into 500kg of water and stirring for 40min to dissolve the OP-10 to obtain an OP-10 solution;

[0032] Step 3, add the 120kg ethanol weighed in step 1 into the remaining 200kg water to obtain an ethanol solution, add the 80kg cetyltrimethylammonium chloride weighed in step 1 into the solution, stir for 20min, and obtain hexadecyl trimethyl ammonium chloride Trimethylammonium chloride solution;

[0033] Step 4, add the OP-10 solution obtained in step 2 to the cetyltrimethylammonium chl...

Embodiment 2

[0035] The present invention provides a kind of preparation method of cleaning wax remover for oil field, specifically implement according to the following steps:

[0036] Step 1, weigh the following components respectively according to mass percentage: OP-10 is 100kg, cetyltrimethylammonium chloride is 60kg, ethanol is 100kg, sodium salicylate is 20kg, water is 720kg, the above groups The sum of the weight percentages of the parts is 100%;

[0037] Step 2, adding 100kg of OP-10 weighed in step 1 into 500kg of water and stirring for 40min to dissolve the OP-10 to obtain an OP-10 solution;

[0038] Step 3, add the 100kg ethanol weighed in step 1 into the remaining 220kg water to obtain an ethanol solution, add the 60kg cetyltrimethylammonium chloride weighed in step 1 into the solution, stir for 15min, and obtain hexadecyl trimethyl ammonium chloride Trimethylammonium chloride solution;

[0039] Step 4, add the OP-10 solution obtained in step 2 to the cetyltrimethylammonium c...

Embodiment 3

[0041] The present invention provides a kind of preparation method of cleaning wax remover for oil field, specifically implement according to the following steps:

[0042] Step 1, take the following components respectively according to the mass percentage: OP-10 is 50kg, cetyltrimethylammonium chloride is 150kg, ethanol is 150kg, sodium salicylate is 40kg, water is 610kg, the above groups The sum of the weight percentages of the parts is 100%;

[0043] Step 2, adding 50kg of OP-10 weighed in step 1 into 500kg of water and stirring for 40min to dissolve the OP-10 to obtain an OP-10 solution;

[0044] Step 3, add the 150kg ethanol weighed in step 1 to the remaining 110kg water to obtain an ethanol solution, add the 150kg cetyltrimethylammonium chloride weighed in step 1 to the solution, stir for 20min, and obtain cetyl trimethyl ammonium chloride Trimethylammonium chloride solution;

[0045] Step 4, add the OP-10 solution obtained in step 2 to the cetyltrimethylammonium chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com