Circulating drying device for biomass energy material processing

A technology of biomass energy and drying device, which is used in biomass drying, granular material drying, drying and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

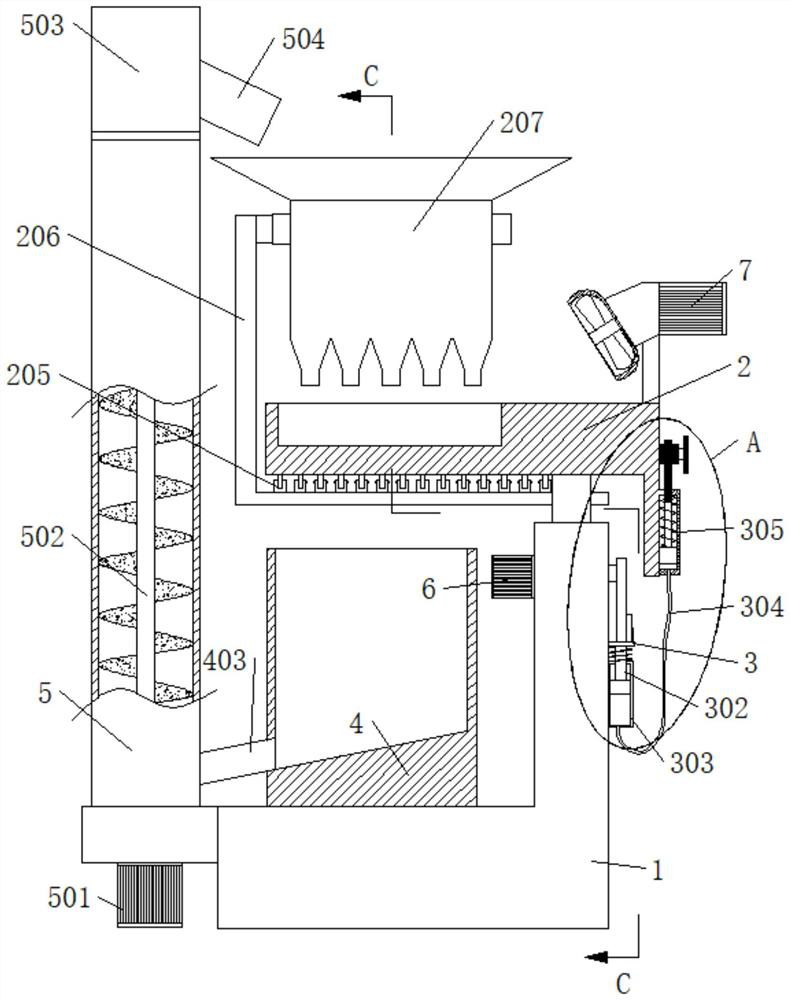

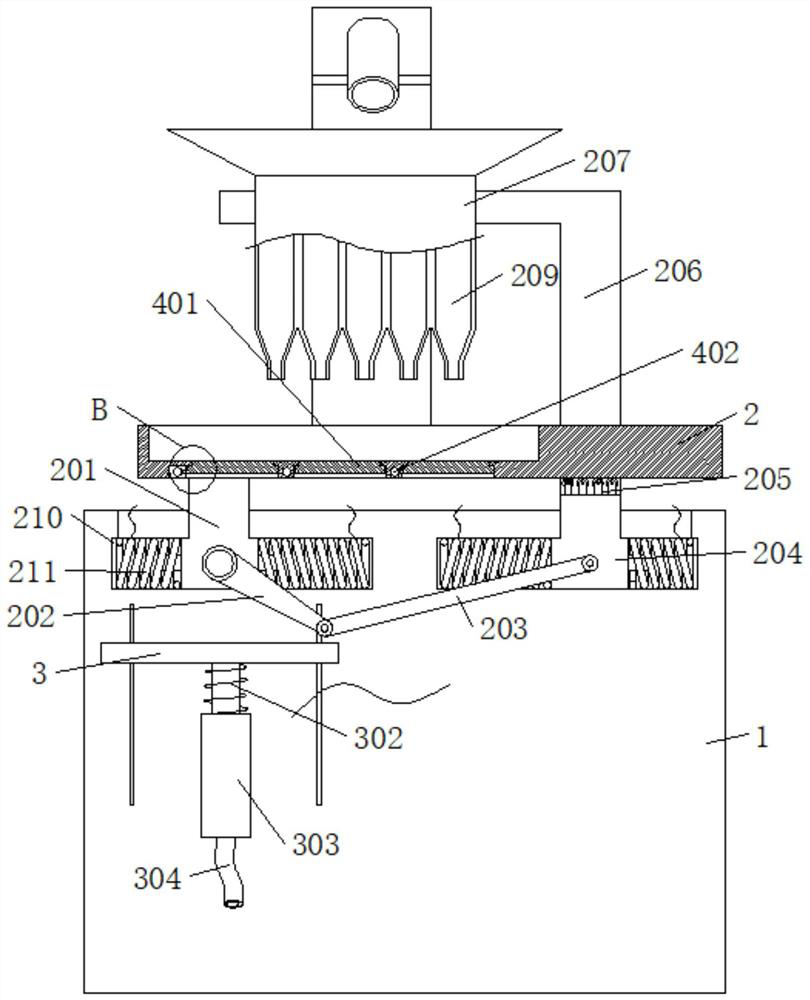

[0028] refer to Figure 1-5 , a circulation drying device for biomass material processing, comprising a base 1, a drying panel 2, a feeding box 207, a transfer box 4, and a feeding box 5; wherein, the feeding box 207 is located above the drying panel 2, and the drying The bottom of the dry panel 2 is rotatably connected with a plurality of baffle plates 401, and the transfer box 4 is located below the drying panel 2; the transfer box 4 is connected to the feeding box 5, and the feeding box 5 is used to transport materials into the feeding box 207; The bottom of the feeding box 207 is connected with a plurality of feeding pipes 209. The present invention puts materials into the feeding box 207 and drives the feeding box 207 to shake in the opposite direction with the drying panel 2 through the first driving part, so that the materials in the feeding box 207 The material is laid flat on the drying panel 2, and the second driving part drives a plurality of baffle plates 401 to fi...

Embodiment 2

[0030] see Figure 1-5, this implementation shared a specific embodiment of the first driving part, which includes the first slider 201 and the second slider 204, the side wall of the base 1 is provided with a through groove 210, the first slider 201 and the second slider The blocks 204 are all slidably connected in the through groove 210, the upper end of the first slider 201 is fixedly connected with the drying panel 2, the upper end of the second slider 204 is fixedly connected with a bracket 206, and the feeding box 207 is fixedly connected with the upper end of the bracket 206. The first motor 6 is installed on the slider 201, the output end of the first motor 6 is connected with the first connecting rod 202, the first connecting rod 202 is connected to the first slider 201 in rotation, and the second slider 204 is connected in rotation with The second connecting rod 203, the end of the second connecting rod 203 away from the second slider 204 is rotationally connected wi...

Embodiment 3

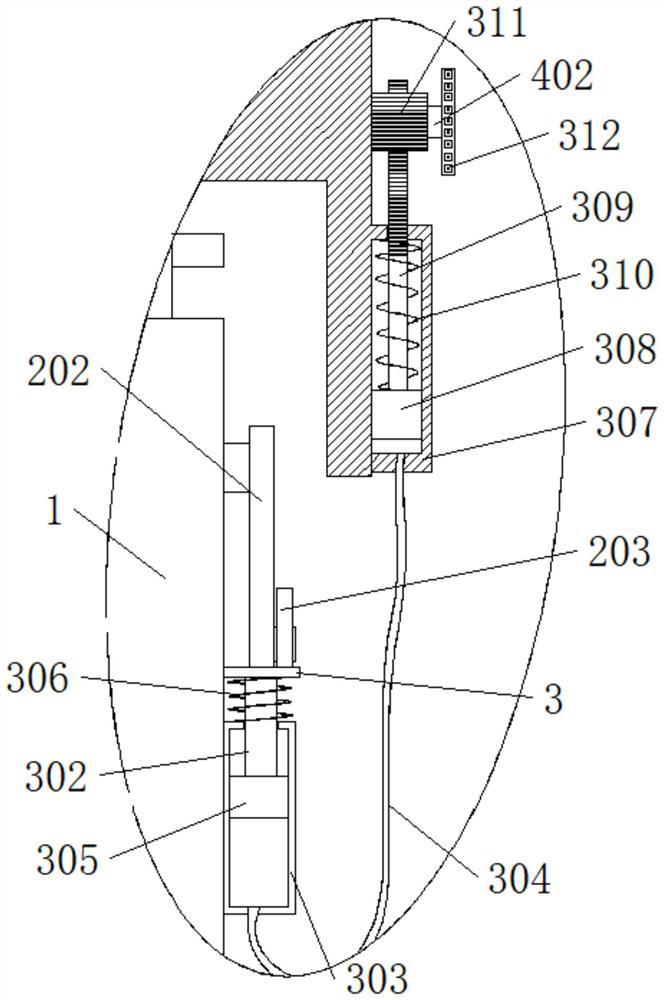

[0032] see Figure 1-5 , this implementation shared a specific embodiment of the second driving part, which includes a slide plate 3 slidably connected to the side wall of the base 1, the slide plate 3 is located below the first connecting rod 202, and is connected to the first connecting rod 202 On the contrary, the side wall of the base 1 is fixedly connected with the first sealed barrel 303, the first sealed barrel 303 is connected with the first piston 305 in a sealed and sliding manner, the first piston 305 is fixedly connected with the first push rod 302, and the upper end of the first push rod 302 It is fixedly connected with the slide plate 3, the drying panel 2 is rotatably connected with a rotating shaft 402, the material retaining plate 401 is fixedly connected with the rotating shaft 402, the extension end of the rotating shaft 402 passes through the side wall of the drying panel 2, and the rotating shaft 402 is fixedly connected with a gear 311, the side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com