Optical fiber temperature sensor

A fiber optic temperature and sensor technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve problems such as difficult remote temperature monitoring, material and structural stability, and achieve reliable mechanical properties and temperature change rates. sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementations of the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific implementation manners described herein are only used to illustrate and explain the embodiments of the present invention, and are not used to limit the embodiments of the present invention.

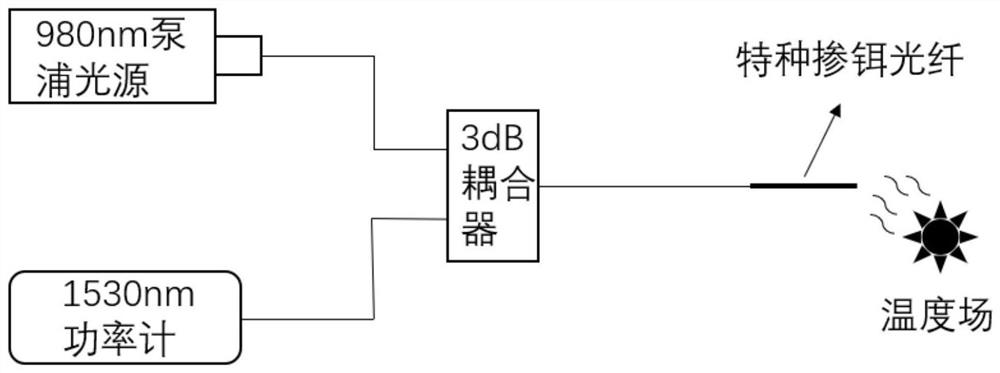

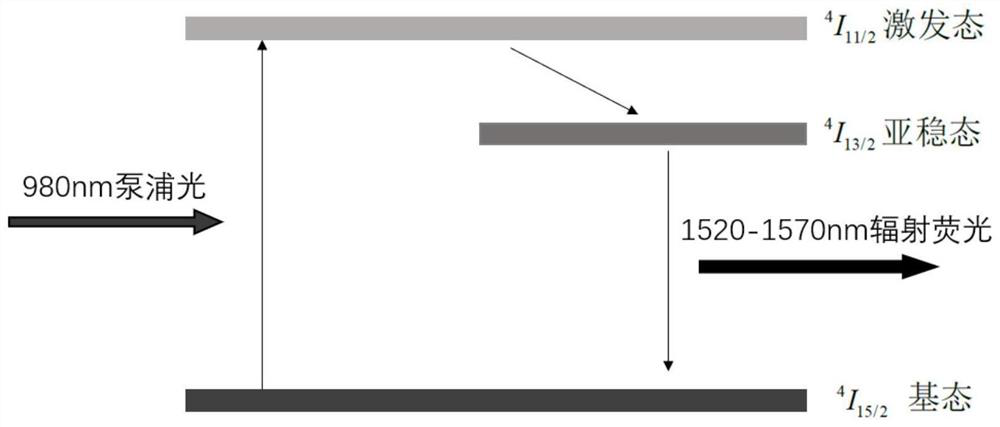

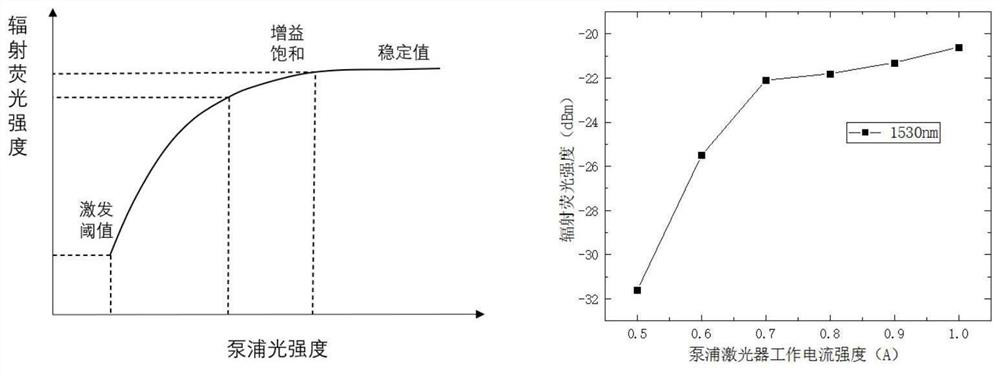

[0021] The present invention relates to a novel optical fiber temperature sensor. Specific examples of the reflective optical fiber temperature sensor include: a 980nm pump light source, a 3dB coupler, an erbium-doped fiber, a single-mode fiber, and a power meter. During operation, a tubular heating furnace is used to simulate the actual temperature detection environment. The specific operation steps are as follows:

[0022] like figure 1 As shown, connect the fiber temperature sensing device, connect the input pigtail of the 980nm pump light source and the input pigtail of the power meter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com