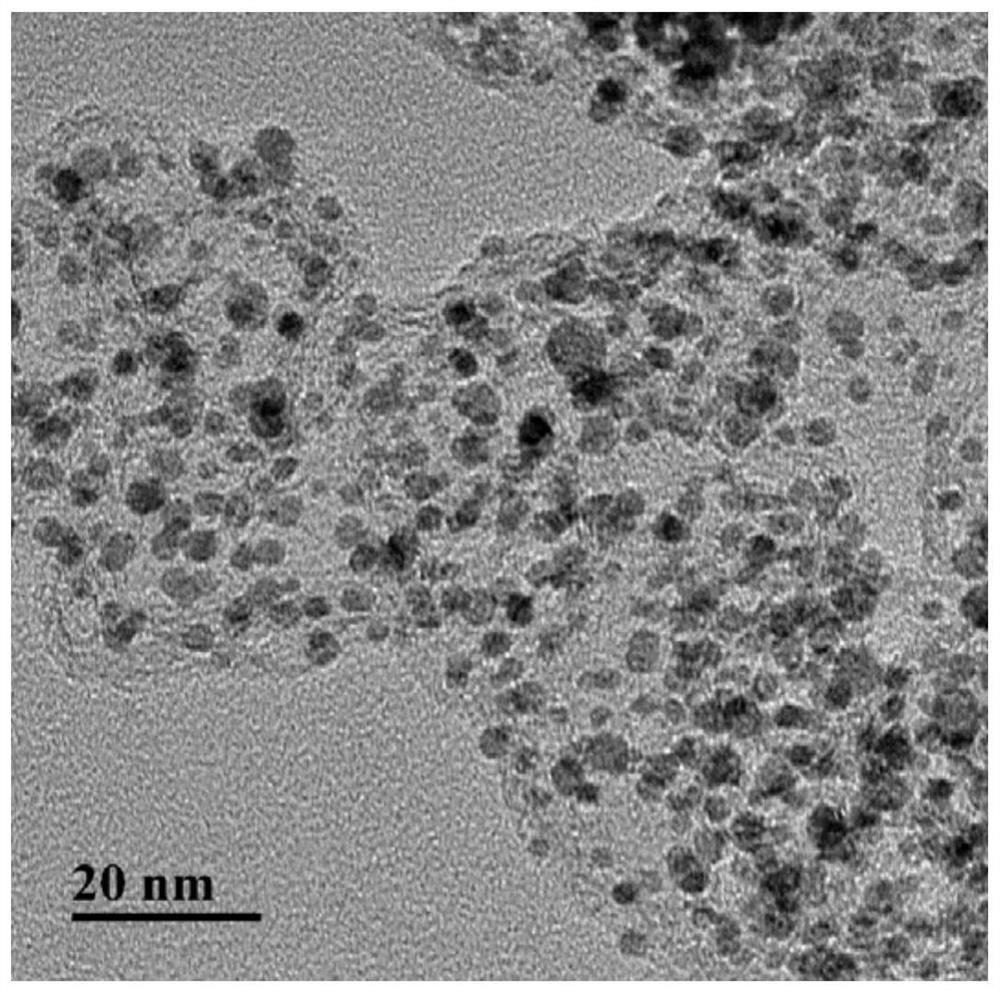

Multi-component alloy catalyst as well as preparation method and application thereof

A multi-element alloy and catalyst technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of large particles, insufficient alloying degree of platinum-carbon catalysts, and inability to fully meet the performance requirements of the catalyst, and achieve high catalyst activity and excellent catalytic performance. Activity and catalytic stability, beneficial to large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In the first aspect, an embodiment of the present invention provides a method for preparing a multi-element alloy catalyst. The multi-element alloy catalyst includes metal platinum and other metals different from platinum, and the other metals include a first metal and a second metal, specifically including The following steps:

[0052] Step S1, prepare carbon material mixed slurry: disperse carbon material in solvent, add platinum source raw material liquid and other metal raw material liquid, and shear and disperse for 0.5-24h, for example, it can be 0.5h, 1h, 5h, 10h, 15h , 20h, 24h, etc., to form a uniform suspension; add additives to the suspension, ultrasonic 0.5 ~ 24h, such as 0.5h, 1h, 5h, 10h, 15h, 20h, 24h, etc., and then at 20 ~ 80 ° C Stir for 0.5-24 hours, for example, the temperature can be 20°C, 30°C, 40°C, 50°C, 60°C, 70°C, 80°C, etc., and the stirring time can be 0.5h, 1h, 5h, 10h, 15h, 20h, 24h, etc. , forming a carbon material mixed slurry;

[0053]...

Embodiment 1

[0091] A preparation method of multi-component alloy catalyst, comprising the following steps:

[0092] Step S1, treat XC-72R carbon black at 2300°C for 12 hours, weigh 5g of XC-72R carbon black and disperse it in 100mL of water, add 20mL of ethylene glycol solution with a concentration of 200g / L chloroplatinic acid, and 5mL with a concentration of 100g / L of nickel sulfate aqueous solution, 5mL of cobalt sulfate aqueous solution with a concentration of 100g / L, and shear and disperse for 0.5h to form a uniform suspension; add 0.5g of ascorbic acid and 0.5g of citric acid monohydrate to the suspension, and ultrasonicate for 0.5h Afterwards, the temperature was raised to 80° C., and stirred for 2 hours to form a carbon material mixed slurry;

[0093]Step S2, put the carbon material mixed slurry obtained in step S1 into a reaction kettle, place the reaction kettle in a microwave oven, react at 180°C for 120min, then press filter and wash, and dry at 80°C for 12h to obtain the dri...

Embodiment 2

[0096] A preparation method of multi-component alloy catalyst, comprising the following steps:

[0097] Step S1, treat graphene at 2300°C for 12 hours, weigh 5g of graphene and disperse it in 100mL of water, add 20mL of ethylene glycol solution with a concentration of 200g / L chloroplatinic acid, and 5mL of an aqueous solution of nickel sulfate with a concentration of 100g / L , 5mL of cobalt sulfate aqueous solution with a concentration of 100g / L, and shear and disperse for 0.5h to form a uniform suspension; add 0.5g of ascorbic acid and 0.5g of citric acid monohydrate to the suspension, and after ultrasonication for 0.5h, heat up to 80°C , and stirred for 2 hours to form a carbon material mixed slurry;

[0098] Step S2, put the carbon material mixed slurry obtained in step S1 into a reaction kettle, place the reaction kettle in a microwave oven, react at 180°C for 120min, then press filter and wash, and dry at 80°C for 12h to obtain the dried The dried powder is first calcined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com