Preparation method and application of navel orange concentrated juice rich in various nutritional ingredients

A technology for concentrated juice and navel orange, which is applied in the field of preparation of navel orange concentrated juice, can solve the problems of obvious flavor gap of natural sources, rough processing, lack of nutrients, etc., and achieves the solution of low resource utilization rate, stable process and improved effective utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention relates to a kind of preparation method of navel orange concentrated juice, comprises the following steps:

[0029] (1) Pre-treatment of raw materials: Navel orange fines are obtained after navel oranges are selected, cleaned and crushed;

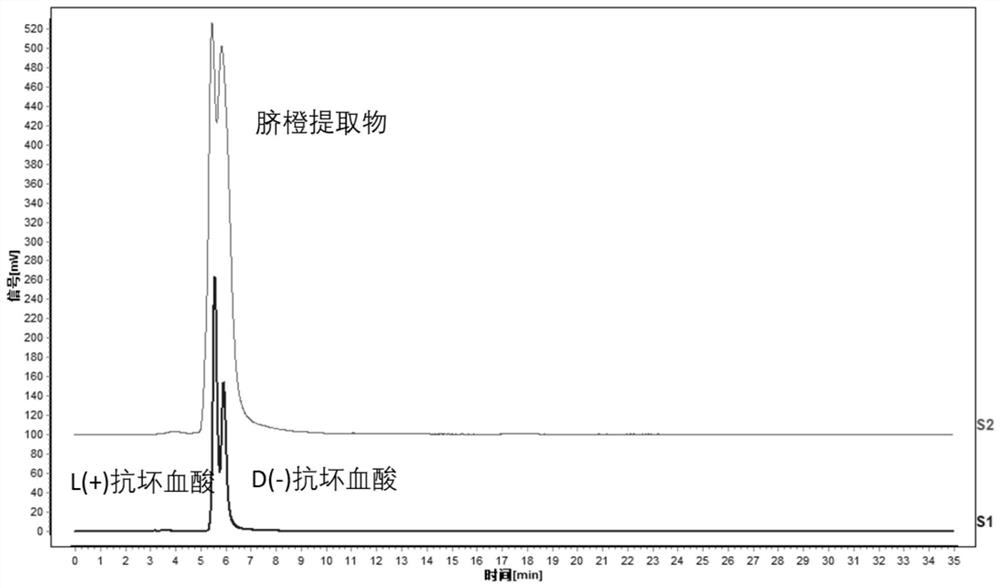

[0030] (2) Extraction: After adding water and mixing the navel orange finely divided material obtained in step (1), carry out low-temperature instant extraction at an extraction temperature of 20-25° C. to obtain navel orange extract;

[0031] (3) Separation and purification, microfiltration: After the navel orange extract obtained in step (2) is centrifuged, take the centrifuged liquid for adsorption on an AB-8 resin column, wash the column with pure water first, and then use a volume fraction of 5-10% Ethanol elution, and then elution with ethanol solution with a volume fraction of 30-50%, each elution until colorless or solid content is less than 0.5%, and the eluate after elution with a volume fraction of 30...

Embodiment 1

[0040] After getting 48kg navel orange raw materials to be cleaned, coarsely crush them into small pieces with a crusher, and then use 2 times the amount of purified water to pass through a 1.2mm sieve for wet crushing (using a high-efficiency turbine pulverizer to crush) to obtain navel orange fine pulp. Add 8 times of purified water to the navel orange fine pulp, stir and mix well, then use emulsification extraction equipment for low-temperature instant extraction, the cycle pressure is 0.4MPa, the temperature is 20°C, and the extraction frequency is 1 time; the navel orange extract is collected and centrifuged. 10000r / min; take the centrifugate and absorb it on the AB-8 resin column, first elute with 10% ethanol by volume fraction, and then elute with 35% ethanol solution by volume fraction, each time until colorless or the solid content is less than 0.5%, collect the eluate after eluting with ethanol solution with a volume fraction of 35%, and remove the alcohol until there...

Embodiment 2

[0042] After getting 30kg navel orange raw materials to be cleaned, coarsely crush them into small pieces with a crusher, and then use 2 times the amount of purified water to pass through a 1.2mm sieve for wet crushing (using a high-efficiency turbine pulverizer to crush) to obtain navel orange fine pulp. Navel orange fine pulp is supplemented with 8 times of purified water, stirred and mixed, and the emulsification extraction equipment is used for low-temperature instant extraction. The cycle pressure is 0.45MPa, the temperature is 20°C, and the extraction frequency is 1. The extract is collected and centrifuged. The centrifuge speed is 10000r / min; take the centrifugate and adsorb it on the AB-8 resin column, first elute with 8% ethanol by volume fraction, and then elute with 30% ethanol solution by volume fraction, each elution until it is colorless or the solid content is less than 0.5%, Collect the eluate after eluting with ethanol solution with a volume fraction of 30%, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com