Microchannel reaction system and technology for continuously synthesizing isopropyl nitrate

A technology of isopropyl nitrate and microchannels is applied in the directions of nitrate preparation, chemical/physical/physicochemical reactors, chemical instruments and methods, and can solve the problems of low yield of isopropyl nitrate and difficult reaction process, etc., To avoid the danger of flying temperature, improve the yield, and avoid the effect of solid waste salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

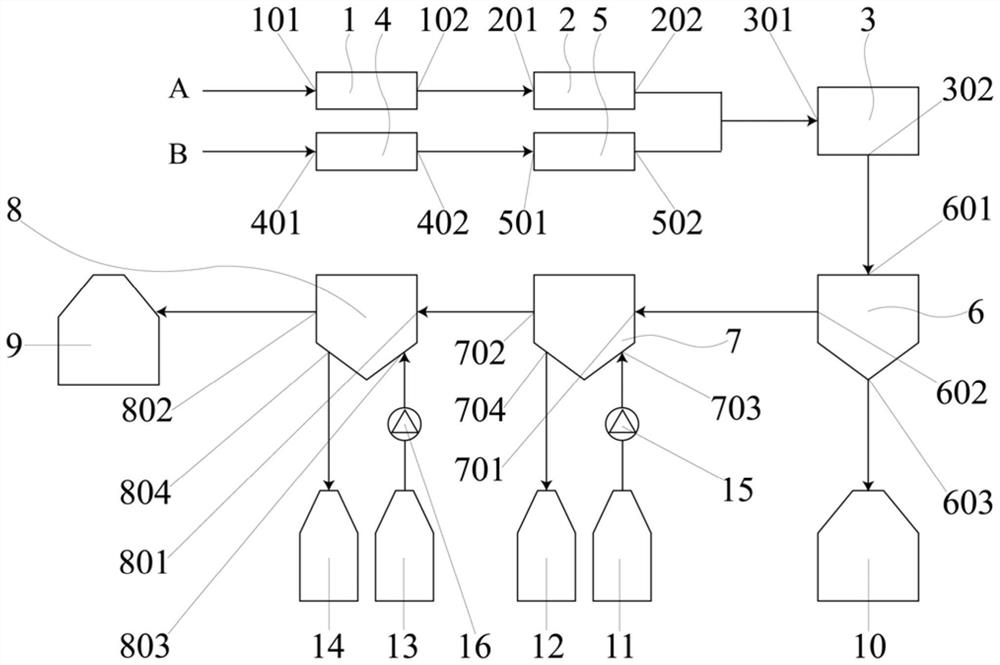

[0060] Present embodiment provides a kind of microchannel reaction system of continuous synthesis isopropyl nitrate, as figure 1 Shown, comprise isopropanol sampling metering pump 1, isopropanol passes into from the sample inlet 101 place of isopropanol sampling metering pump 1, the sample outlet 102 of isopropanol sampling metering pump 1 is connected with microchannel The sample inlet 201 of the isopropanol precooler 2 is connected, and the sample outlet 202 of the microchannel isopropanol precooler 2 is connected with the sample inlet 301 of the microchannel nitration reaction device 3;

[0061] Also includes nitric acid sampling metering pump 4, high-purity refined nitric acid is introduced from the sample inlet 401 of nitric acid sampling metering pump 4, the sample outlet 402 of nitric acid sampling metering pump 4 is connected to the inlet of microchannel nitric acid precooling device 5 The sample port 501 is connected, and the sample outlet 502 of the microchannel nitr...

Embodiment 2

[0068] The present embodiment provides a kind of technique of continuous synthesis of isopropyl nitrate, and this technique adopts the microchannel reaction system of continuous synthesis of isopropyl nitrate in embodiment 1. The process specifically includes the following steps:

[0069] Step 1, prepare preliminary reaction product:

[0070] Step 1.1, pre-cool raw materials:

[0071] Set the precooling temperature of the microchannel isopropanol precooling device 2 to 5°C, use the isopropanol injection metering pump 1 to control the injection flow rate of isopropanol to 12.8mL / min, add isopropanol to the micro Channel isopropanol pre-cooling device 2 for cooling. Set the precooling temperature of the microchannel nitric acid precooling device 5 to 5°C, use the nitric acid sampling metering pump 4 to control the injection flow rate of the high-purity refined nitric acid to 7mL / min, and add the high-purity refined nitric acid to the microchannel nitric acid precooling unit. ...

Embodiment 3

[0083] The present embodiment provides a kind of technique of continuous synthesis of isopropyl nitrate, and this technique adopts the microchannel reaction system of continuous synthesis of isopropyl nitrate in embodiment 1. The process specifically includes the following steps:

[0084] In this embodiment, step 1 is basically the same as step 1 of embodiment 2, the difference is:

[0085] In step 1.1, the precooling temperature of the microchannel isopropanol precooling device 2 and the microchannel nitric acid precooling device 5 were both 10°C, and the injection flow rate of the high-purity refined nitric acid was controlled at 8.7mL / min. In step 1.2, the reaction temperature of the microchannel nitration reaction device 3 is set to 10° C., and the average residence time of isopropanol and high-purity refined nitric acid in the microchannel nitration reaction device 3 is 25.0 s.

[0086] In this embodiment, step 2 is basically the same as step 2 of embodiment 2, the diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com