Patch type fuse and batch manufacturing method thereof

A fuse and chip-type technology, which is applied in the field of fuses with low-temperature rise performance and batch manufacturing, can solve the problems of terminal electrodes and fuses falling off, deformation of insulating shells, and difficulty in heat dissipation, etc., to improve long-term use reliability , The heat dissipation area is increased, and there is no effect of heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

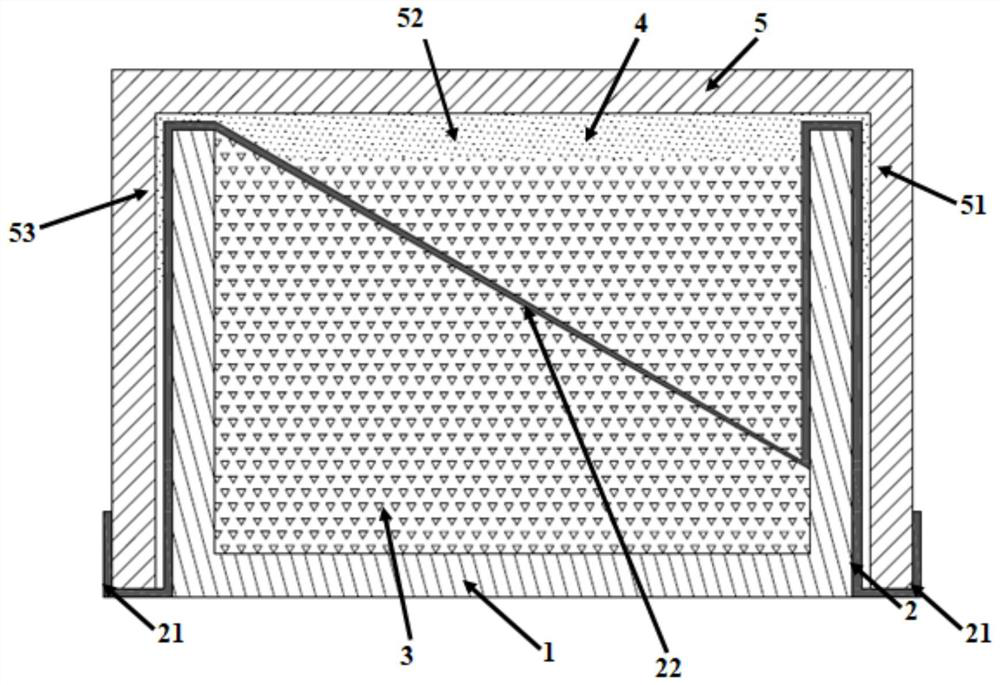

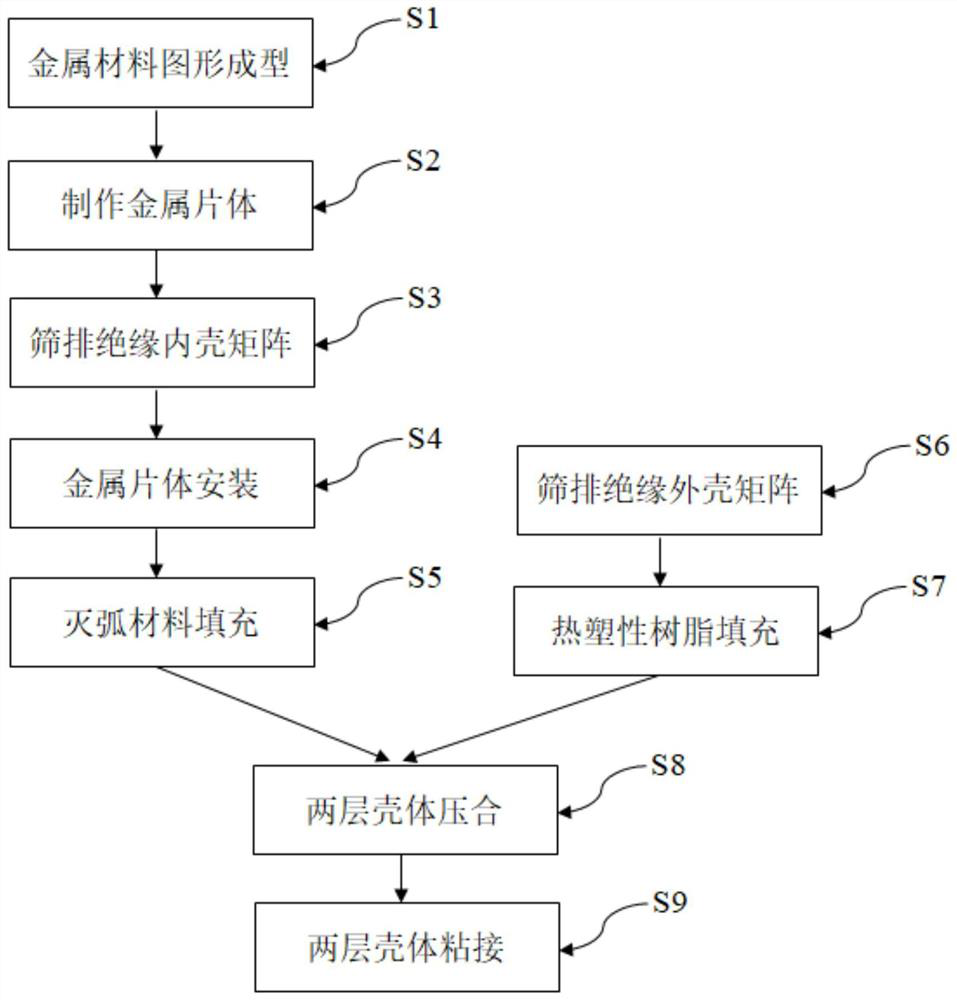

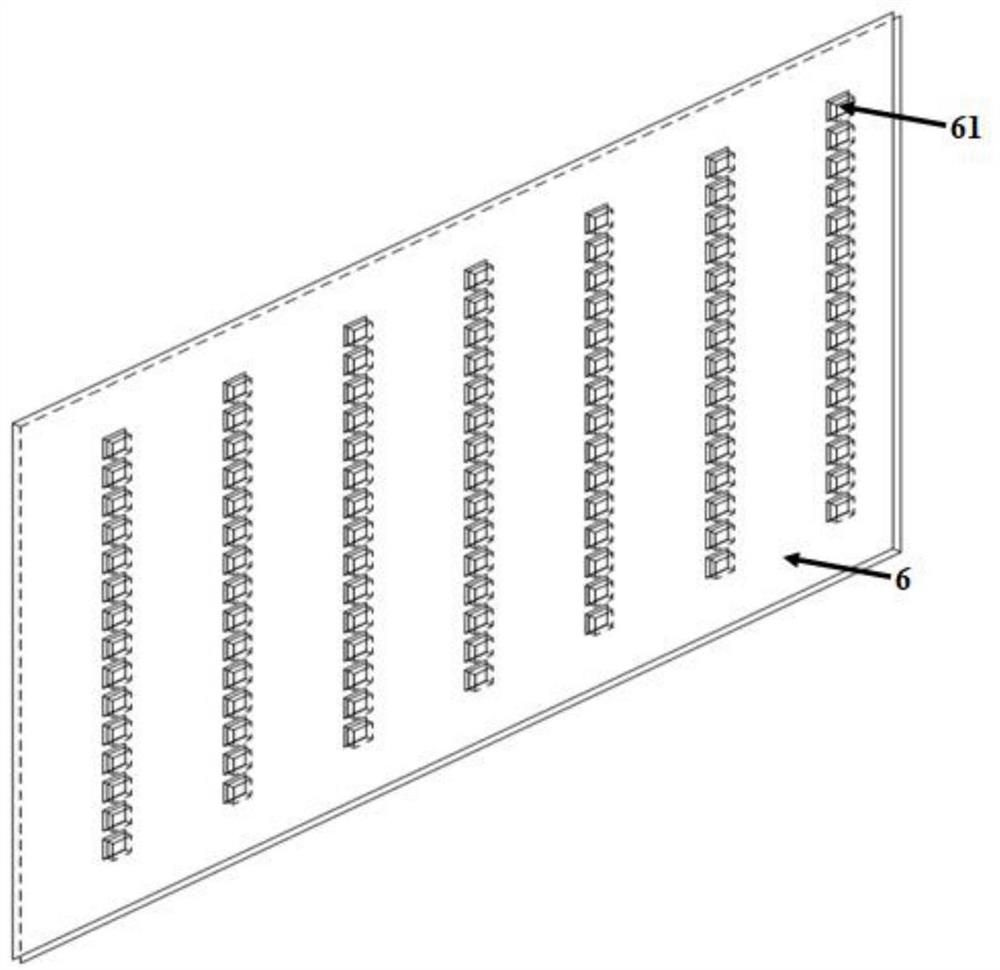

[0036] Such as figure 1As shown, the chip fuse includes an insulating inner shell 1 , an insulating outer shell 5 , a metal sheet 2 , an arc-extinguishing material 3 , and a high-temperature thermoplastic resin 4 . The insulating inner shell 1 is a rectangular parallelepiped shell with four first side walls and a bottom surface, the insulating shell 5 is a rectangular parallelepiped shell with four second side walls and a top face, and the edge shell 5 is covered by the insulating inner shell 1 Peripherally, the first side wall of the insulating inner shell 1 forms a cavity together with the top surface and the bottom surface. The arc extinguishing material 3 fills the cavity of the insulating inner shell 1 . There are gaps 51 and 53 between the upper half of the first side wall and the upper half of the second side wall, and there is a gap 52 between the inner side of the top surface of the insulating shell 5 and the upper surface of the arc-extinguishing material 3 filled i...

Embodiment 2

[0049] combine figure 1 and as Figure 6 The metal sheet 2 includes two end electrodes 21 and a fuse 22 integrally formed, wherein the fuse 22 is distributed in the inner cavity of the insulating inner shell 1 and is inclined relative to the bottom surface of the insulating inner shell 1. A circular hole is set in the middle of the body 22 , one end of the fuse body 22 abuts against the wall opening inside the first side wall, and the other end abuts against the corresponding inner side of the first side wall. One end of the fuse 22 is bent and extended to extend out an extension portion 23, which extends from the wall opening of the first side wall, extends downward against the outside of the first side wall, and protrudes to the bottom edge of the second side wall, The protruding end electrode 21 is parallel to the outer side of the second side wall; the other end of the fuse 22 is bent and extended out of the extension part 23, and the extension part sticks to the inner si...

Embodiment 3

[0051] The structures of the insulating inner shell 1 and the insulating outer shell 5 in the chip type fuse of the present invention are as follows: Figure 7 shown. Figure 7 (a) is the basic structure of the insulating case 5 , and the insulating case 5 includes four side walls, 51 , 52 , 53 , 54 in sequence, and a top surface 55 . Figure 7 (b) is the basic structure of the insulating inner shell 1. The insulating inner shell 1 includes four side walls, which are 11, 12, 13, 14 in sequence, and a bottom surface 15. The inner cavity of the insulating inner shell 1 is a cylinder 15. The distance between the opposite two side walls in the insulating inner shell 1, such as the distance between 11 and 13 and the distance between 12 and 14, is smaller than the distance between the corresponding two side walls in the insulating shell 5, that is, the above-mentioned distance is less than The distance between 51 and 53 and the distance between 52 and 54 are to ensure that the insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com