Degradable adhesive and application thereof in preparation of degradable and recyclable artificial board

A technology of adhesives and additives, applied in the preparation of degradable and recycled wood-based panels, and the field of degradable adhesives, can solve the problems of short service life and adverse consequences of wood-based panels, and achieve the effect of reducing pollution and saving wood resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

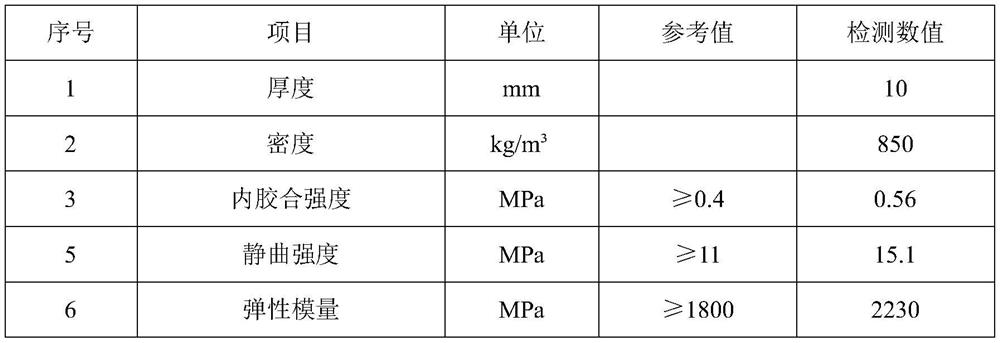

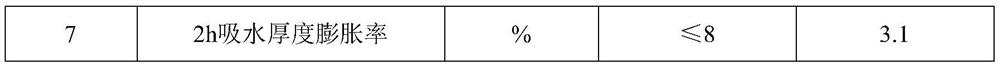

Examples

Embodiment 1

[0034] Preparation of biodegradable adhesives

[0035] The degradable adhesive is an adhesive with a certain viscosity formed by adding auxiliary agents such as tackifier, accelerator, antioxidant and anti-hydrolysis agent to the copolyester.

[0036] Described copolyester synthetic method is as follows:

[0037] (1) Esterification stage: glycolic acid 2mol, lactic acid 5mol, maleic anhydride 0.5mol, butylene glycol 1mol, glycolic acid, lactic acid, maleic anhydride and butylene glycol are added in the reactor in order, Add a titanium dioxide catalyst with 0.5% molar amount of total acid, the stirring rate is 60r / min, and the esterification adopts the method of gradually increasing the temperature and increasing the vacuum: ①Reaction temperature 130°C, vacuum -0.02MPa, esterification time 1h; ②Reaction temperature 150°C, Vacuum-0.04MPa, esterification time 1h; ③reaction temperature 170℃, vacuum-0.07MPa, esterification time 1h; ④reaction temperature 180℃, vacuum-0.08MPa, ester...

Embodiment 2

[0056] Preparation of biodegradable adhesives.

[0057] The degradable adhesive is an adhesive with a certain viscosity formed by adding auxiliary agents such as tackifier, accelerator, antioxidant and anti-hydrolysis agent to the copolyester.

[0058] Described copolyester synthetic method is as follows:

[0059] (1) Esterification stage: glycolic acid 1mol, lactic acid 6mol, maleic anhydride 1mol, butylene glycol 1.8mol, glycolic acid, lactic acid, maleic anhydride and butylene glycol are added in the reactor in order, Add tetrabutyl titanate catalyst with 0.5% molar amount of total acid, the stirring rate is 80r / min, and the esterification adopts the method of gradually raising the temperature and increasing the vacuum: ①reaction temperature 110°C, vacuum -0.02MPa, esterification time 2h; ②reaction Temperature 140°C, vacuum -0.04MPa, esterification time 1h; ③ reaction temperature 160°C, vacuum -0.07MPa, esterification time 1h; ④ reaction temperature 170°C, vacuum -0.08MPa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com