Degradable polymer composite paper prepared from Pickering emulsion and method

A Pickering emulsion and polymer technology, used in special paper, paper, papermaking, etc., can solve the problems of poor paper strength, difficult to decompose, easy to damage, etc., to achieve good biocompatibility, enhanced functionality, and wide application Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] With dichloromethane as the oil phase and deionized water as the water phase, 1.2g of degradable polymer material PLA was completely dissolved in 20mL of dichloromethane, and then the two phases were mixed according to the ratio of oil:water=2:1, and 0.05 % nano-silica particles, sheared by a high-speed shearing machine at 5000 rmp for 5 min to obtain a degradable polymer Pickering emulsion, take 10 mL of the obtained polymer emulsion, and evenly coat it on the qualitative filter paper with a glass rod, heat at 180 ° C. Press for 10 min to obtain degradable polymer composite paper.

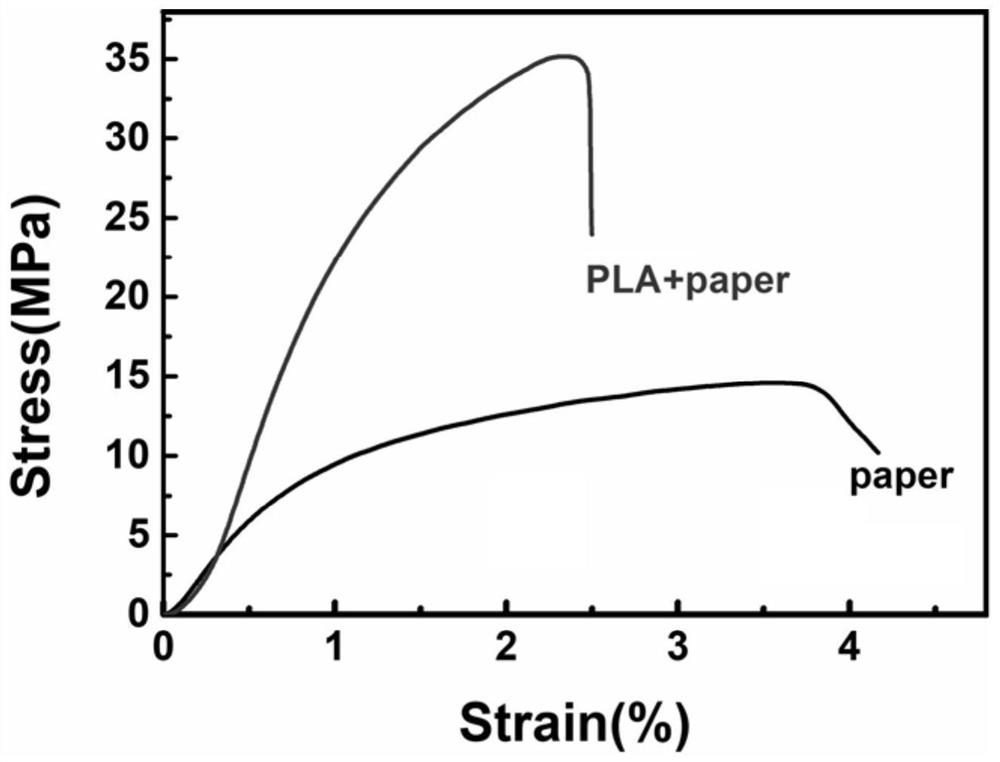

[0029] Use a servo tensile testing machine to measure the tensile strength of ordinary filter paper and composite paper, such as figure 1 As shown, compared with the tensile strength of ordinary filter paper, the tensile strength of PLA composite paper increased to 35MPa, and the mechanical properties were significantly enhanced.

Embodiment 2

[0031] With dichloromethane as the oil phase and deionized water as the water phase, 1.2g of degradable polymer material PLA was completely dissolved in 20mL of dichloromethane, and then the two phases were mixed according to the ratio of oil:water=2:1, and 0.05 % nano-montmorillonite, sheared by a high-speed shearing machine at 5000 rmp for 5 min to obtain a degradable polymer Pickering emulsion, take 10 mL of the obtained polymer emulsion, evenly coat it on qualitative filter paper with a glass rod, and heat at 180 °C. Press for 10 min to obtain degradable polymer-based composite paper.

Embodiment 3

[0033] With dichloromethane as the oil phase and deionized water as the water phase, 1.2g of degradable polymer material PBAT was completely dissolved in 20mL of dichloromethane, then the two phases were mixed according to the ratio of oil:water=1:2, and 0.05 % nano-montmorillonite, sheared by a high-speed shearing machine at 5000 rmp for 5 min to obtain a degradable polymer Pickering emulsion, take 10 mL of the obtained polymer emulsion, evenly coat it on qualitative filter paper with a glass rod, heat at 150 °C Press for 10 min to obtain degradable polymer-based composite paper.

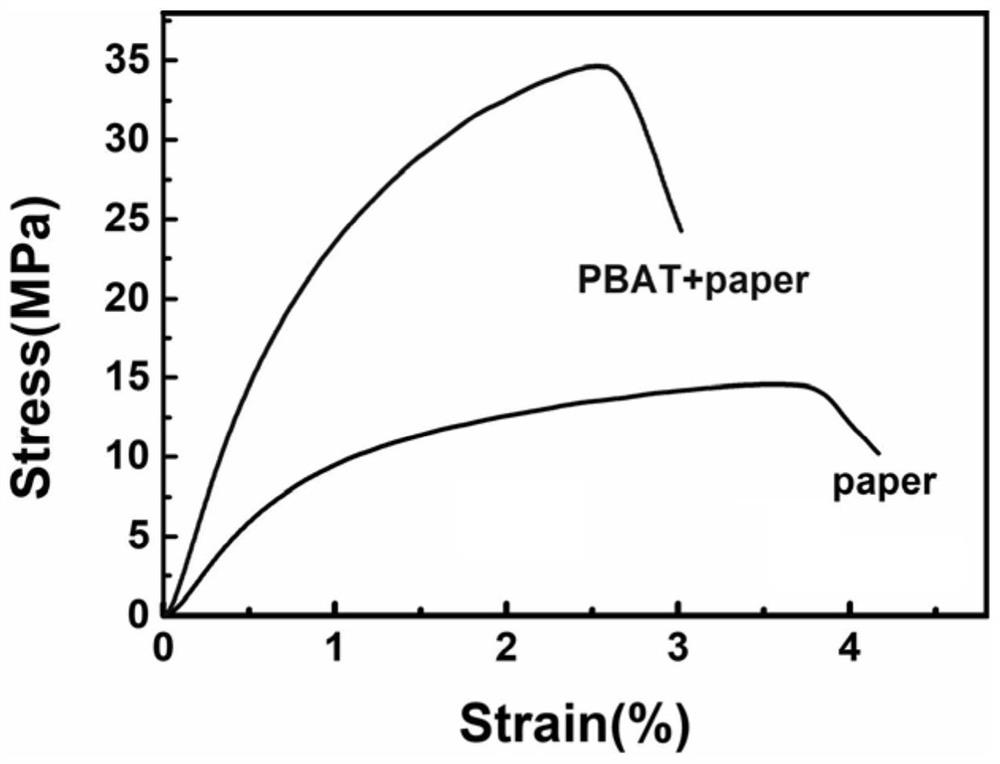

[0034] like figure 2 As shown, compared with the tensile strength of ordinary filter paper, the tensile strength of PBAT composite paper increased to 34.7MPa, and the mechanical properties were significantly enhanced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com