A kind of environment-friendly and degradable flame-retardant polyurethane rapid packaging material and preparation method thereof

A packaging material and flame-retardant technology, which is applied in the field of environmentally friendly degradable flame-retardant polyurethane rapid packaging materials and its preparation, can solve the problems of cumbersome operation, easy foam shrinkage, and affecting foam performance, so as to achieve easy availability of raw materials and reduce Environmental pollution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

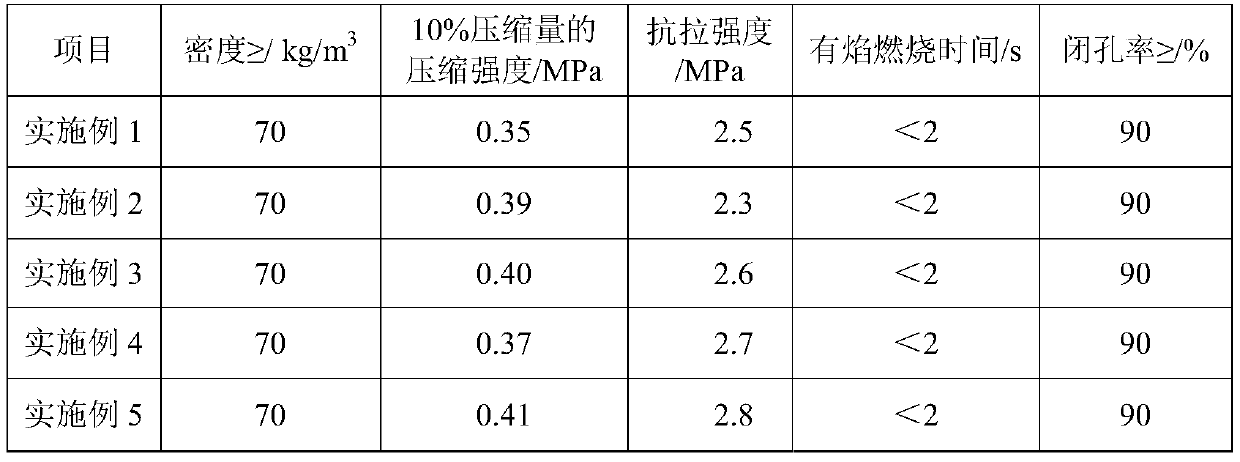

Embodiment l

[0046] A method for preparing an environmentally friendly and degradable flame-retardant polyurethane fast packaging material, comprising the following steps:

[0047] (1) Add 50 parts of distilled water into the container, heat and stir, heat to 100°C, add 20 parts of corn starch, stir for 50 minutes to make the corn starch completely gelatinized, continue heating, and slowly add the complex polyether polyol 50 parts (a mixture of YNW-5112 and YNW-6001B with a mass ratio of 1:1), 10 parts of sucrose polyether polyol (YNW-4110), stirred and reacted for 15 minutes, controlled the viscosity of the system, and then lowered the temperature of the system to 65°C. Stirring reaction 30min, obtains biomass starch polyether polyol;

[0048] (2) Take 80 parts from the above-mentioned liquefied product and put them into No. 1 reactor, add 15 parts of polyester polyol, 2 parts of foam stabilizer (L6900), 20 parts of aluminum hydroxide, 10 parts of blowing agent (HCFC -141b), 0.3 parts of...

Embodiment 2

[0051] A method for preparing an environmentally friendly and degradable flame-retardant polyurethane fast packaging material, comprising the following steps:

[0052] (1) Add 50 parts of distilled water into the container, heat and stir, heat to 100°C, add 20 parts of corn starch, stir for 50 minutes to make the corn starch completely gelatinized, continue heating, and slowly add the complex polyether polyol 60 parts (a mixture of YNW-5112 and YNW-5110 with a mass ratio of 1:2), 10 parts of sucrose polyether polyol (YNW-8336), stirred and reacted for 15 minutes, controlled the viscosity of the system, and then lowered the temperature of the system to 65°C. Stirring reaction 30min, obtains biomass starch polyether polyol;

[0053] (2) Take 90 parts from the above-mentioned liquefied product and put them into No. 1 reactor, add 18 parts of polyester polyol, 3 parts of foam stabilizer (L618), 30 parts of aluminum hydroxide, 20 parts of blowing agent (HCFC -245fa), 0.4 parts of ...

Embodiment 3

[0056] A method for preparing an environmentally friendly and degradable flame-retardant polyurethane fast packaging material, comprising the following steps:

[0057] (1) Add 50 parts of distilled water into the container, heat and stir, heat to 100°C, add 20 parts of corn starch, stir for 50 minutes to make the corn starch completely gelatinized, continue heating, and slowly add the complex polyether polyol 80 parts (a mixture of YNW-5112, YNW-5110 and YNW-8110 with a mass ratio of 1:2:1), 20 parts of sucrose polyether polyol (YNW-380), stirring and reacting for 15 minutes, controlling the viscosity of the system, and then reducing The temperature of the system reaches 65°C, and the reaction is stirred for 30 minutes to obtain the biomass starch polyether polyol;

[0058] (2) Take 100 parts from the above-mentioned liquefied product and put them into No. 1 reactor, add 20 parts of polyester polyol, 4 parts of foam stabilizer (L6603), 30 parts of aluminum hydroxide, 20 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com