Carbon black magnetic separation device

A magnetic separation device and carbon black technology, applied in magnetic separation, solid separation, grain processing, etc., can solve the problems of low removal rate of steel wire debris, secondary pollution of the environment, large amount of dust, etc., and achieve improved screening rate , Low production cost, and the effect of reducing dust generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

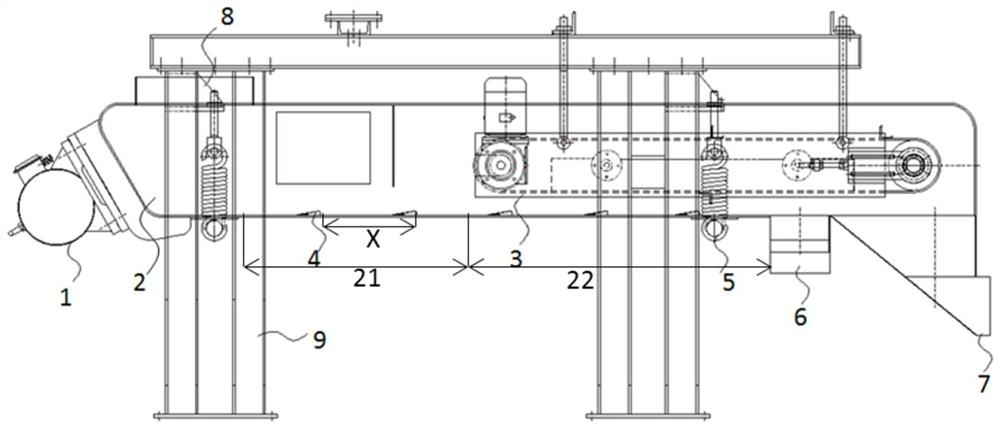

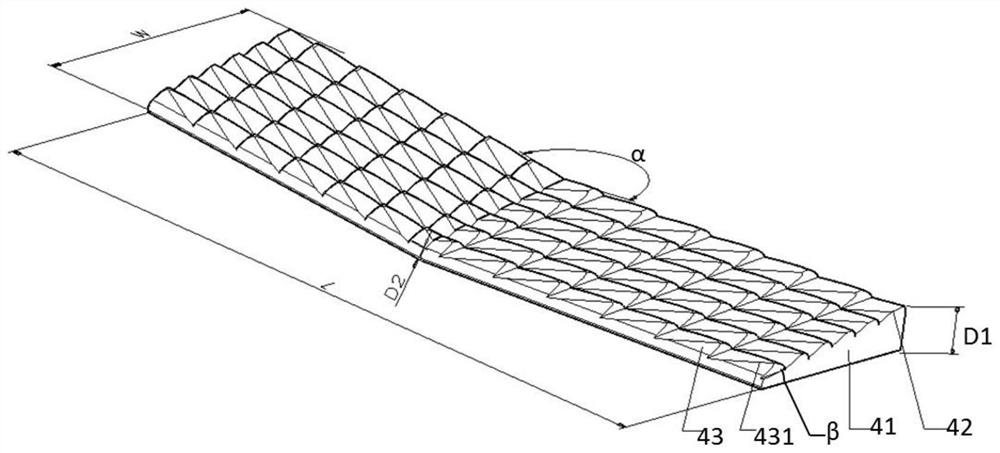

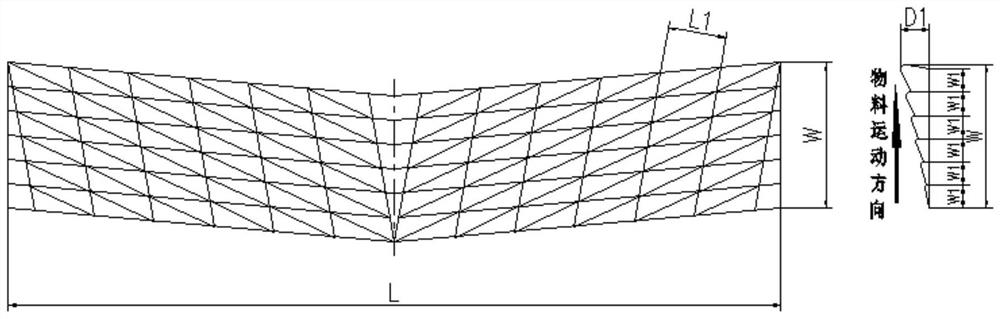

[0061] Such as figure 1 In the carbon black magnetic separation device shown, the vibrator 1 is connected to the vibrating bed 2 to drive the vibrating bed 2 to vibrate. The vibrating bed 2 sequentially includes a paving vibratory crushing section 21 and a magnetic separation section 22 along the moving direction of the material, and the magnetic separation assembly 3 is suspended above the magnetic separation section 22 for magnetically separating the scrap steel wire debris in the carbon black passing through the magnetic separation section 22 . In the direction of material movement, a plurality of material leveling parts 4 are arranged on the vibrating bed 2 . The structure of material paving part 4 is as figure 2 with image 3 shown.

[0062] The material paving piece includes a base 41, the bottom surface of the base 41 is a plane; the direction from front to back of the base is the direction of material movement; the view from front to back of the upper surface of t...

Embodiment 2

[0068] Such as Figure 4 The application process of the carbon black magnetic separation device 16 shown. Waste rubber tire enters feeder 13 through feeder 12, and feeder 13 throws waste rubber tire into pyrolysis reactor 11, and pyrolysis reactor 11 is heated by hot blast stove 10 delivery hot blast. The waste rubber tires undergo pyrolysis reaction in the pyrolysis reactor 11 to generate pyrolysis oil gas and pyrolysis carbon black. The pyrolysis oil gas is cooled by the condensing device to generate pyrolysis oil, and the pyrolysis carbon black containing 5% to 8% of scrap steel wire debris is continuously and quantitatively transported to the In the carbon black magnetic separation device 16, through the flattening, vibration crushing and magnetic separation of the carbon black magnetic separation device 16, scrap steel wire debris and carbon black particles are separated. Scrap steel wire debris is sent into the scrap steel wire debris collector 20, and the pure pyrolyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com