Pavement conductive wearing layer with snow melting and deicing functions and preparation method thereof

A wear layer and functional technology, applied in conductive coatings, coatings, chemical industries, etc., can solve the problems of ineffective ice breaking and low destructive force of the ice layer, and achieve the effects of low cost, convenient construction and maintenance, and high energy utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

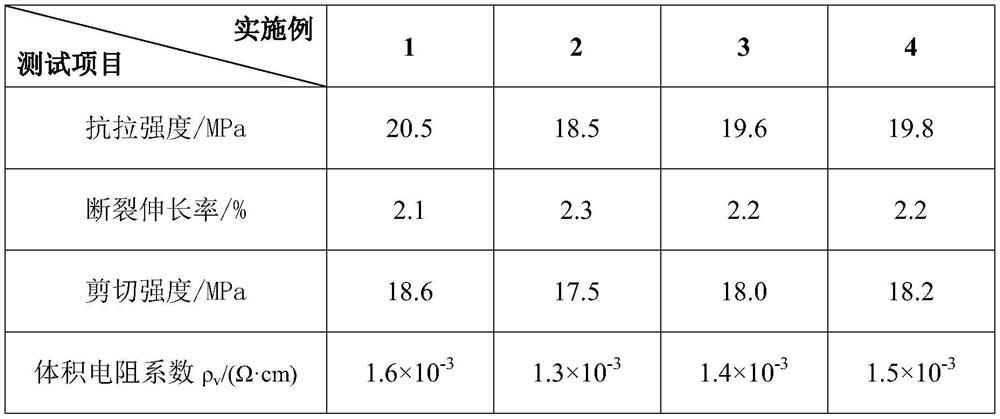

Examples

Embodiment 1

[0026] 1) The formula of component A in parts by mass is: 80 parts of hydrogenated bisphenol A epoxy resin, 10 parts of polyurethane containing carboxyl active groups, 15 parts of polyphenoxy resin PKHB, 5 parts of diglycidyl aniline, 0.1 part of BYK-066N, 0.1 part of BYK-163, and 0.5 part of fumed silica; select each raw material according to the stated ratio, and add them to the mixer in turn, the stirring speed is 400 rpm, and the group A is obtained after stirring for 5 minutes points, packaged for storage.

[0027] 2) The formula of component B in terms of parts by mass is: 70 parts of polyoxypropylene triamine T-403, 10 parts of isophorone diamine, 30 parts of meta-xylylene diamine, and 8 parts of o-hydroxybenzyl dimethylamine , 1 part of isopropyl tris (isostearyl) titanate, 0.1 part of pigment zinc powder, and 0.5 part of fumed silica; select each raw material according to the stated ratio, and add them to the high-speed dispersing kettle in turn, and the speed of the ...

Embodiment 2

[0031] 1) The formula of component A in parts by mass is: 70 parts of hydrogenated bisphenol A epoxy resin, 5 parts of polyurethane containing hydroxyl active groups, 10 parts of polyphenoxy resin PKHB, 10 parts of diglycidyl aniline, 0.3 parts of BYK-066N, 0.3 parts of BYK-163, and 1.5 parts of fumed silica; each raw material is selected according to the above ratio, and added to the mixer in turn, the stirring speed is 350 rpm, and the group A is obtained after stirring for 10 minutes points, packaged for storage.

[0032] 2) The formula of component B in parts by mass is: 50 parts of polyoxypropylene triamine T-403, 20 parts of isophorone diamine, 10 parts of m-xylylene diamine, 3 parts of o-hydroxybenzyl dimethylamine , 2 parts of isopropyl tris (isostearyl) titanate, 0.5 part of pigment zinc powder, and 1.5 parts of fumed silica; each raw material is selected according to the stated ratio, and added to the high-speed dispersion kettle in turn, and the speed of the dispers...

Embodiment 3

[0036] 1) The formula of component A in parts by mass is: 75 parts of hydrogenated bisphenol A epoxy resin, 7 parts of polyurethane containing epoxy active groups, 12 parts of polyphenoxy resin PKHB, 8 parts of diglycidyl aniline 1 part, 0.2 part of BYK-066N, 0.2 part of BYK-163, 1 part of fumed silica; choose each raw material according to the stated ratio, and add them to the mixer in turn, the stirring speed is 400 rpm, and after stirring for 8 minutes, you can get A component, packaged for storage.

[0037] 2) The formula of component B in parts by mass is: 60 parts of polyoxypropylene triamine T-403, 15 parts of isophorone diamine, 20 parts of m-xylylene diamine, 5 parts of o-hydroxybenzyl dimethylamine , 1.5 parts of isopropyl tris (isostearyl) titanate, 0.3 part of pigment zinc powder, and 1 part of fumed silica; each raw material is selected according to the stated ratio, and added to the high-speed dispersion kettle in turn, and the speed of the dispersion disc is 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com