Flip semiconductor light-emitting element, semiconductor light-emitting device and display device

A technology for light-emitting components and semiconductors, applied in semiconductor devices, electric solid-state devices, electrical components, etc., can solve problems such as poor die bonding, electrode pad breakage, affecting device reliability, etc., and achieve good morphology and enhanced adhesion. , the effect of enhancing stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

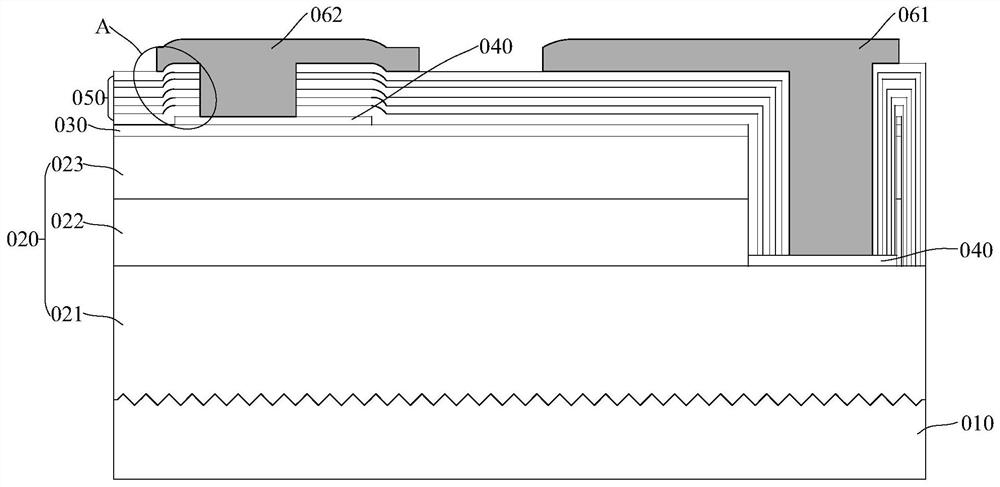

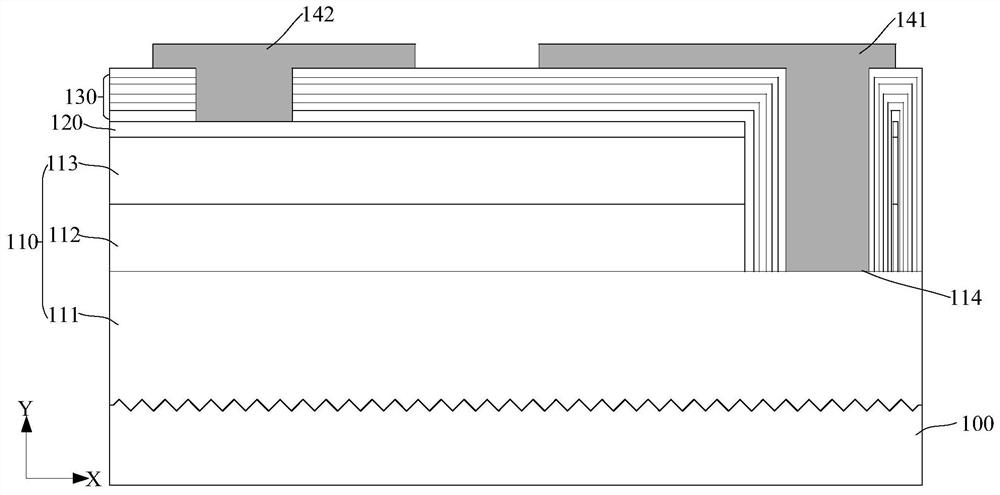

[0068] This embodiment provides a flip-chip semiconductor light-emitting element, such as figure 2 As shown, the semiconductor light emitting element of this embodiment includes a substrate 100, a light emitting epitaxial layer 110 formed on the substrate, and the light emitting epitaxial layer 110 includes a first conductivity type semiconductor layer 111, an active layer formed on the substrate 100 in sequence, layer 112 and the second conductivity type semiconductor layer 113 .

[0069] In this embodiment, the substrate 100 may be an insulating substrate. The substrate 100 may be a growth substrate for growing the light-emitting epitaxial layer 110 , for example, including a sapphire substrate. Such as figure 2 As shown, the substrate 100 further includes a plurality of protrusions formed on at least a part of the upper surface thereof. The plurality of protrusions of the substrate 100 may be formed in regular and / or irregular patterns. For example, the substrate 100 ...

Embodiment 2

[0085] This embodiment also provides a flip-chip semiconductor light-emitting element, and the similarities with the semiconductor light-emitting element provided in Embodiment 1 will not be repeated, but the difference lies in:

[0086] In this embodiment, the insulating layer 130 further includes a third insulating protective layer, wherein the third insulating protective layer is interposed between the first insulating protective layer and the insulating reflective layer, and the third insulating protective layer has a high density It is better than the compactness of the insulating reflective layer, but lower than that of the first insulating protective layer. The first insulating layer is obtained by ALD deposition, for example, an aluminum oxide layer, and the third insulating protection layer is obtained by PECVD deposition, such as a silicon oxide layer, and the thickness of the third insulating protection layer is between 80nm and 450nm. More preferably, the thickness...

Embodiment 3

[0088] This embodiment also provides a flip-chip semiconductor light-emitting element, and the similarities with the semiconductor light-emitting element provided in Embodiment 1 will not be repeated, but the difference lies in:

[0089] The insulating layer 130 in this embodiment includes a fourth insulating protective layer, wherein the fourth insulating protective layer is between the second insulating protective layer and the insulating reflective layer, and the density of the fourth insulating protective layer is higher than that of the insulating reflective layer. The density of the layer is lower than that of the second insulating protective layer. The second insulating layer is obtained by ALD deposition, such as an aluminum oxide layer, and the fourth insulating protective layer is obtained by a PECVD deposition process, such as a silicon oxide layer or a silicon nitride layer. Preferably, the thickness of the second insulating protective layer is between In 8nm-200nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com